- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Monthly Archives: October 2016

-

Posted: October 24, 2016Categories: Wet Processing StationsRead more »

What is a Semiconductor?

“Semi-conductors,” also known as integrated circuits (ICs) or chips, are components with more electrical conductivity than insulators, but less electrical conductivity than conductors, as measured by the potential activity of charged electrons. They are ubiquitous in our society: anything with an ON/OFF switch contains an integrated circuit. Metalloid elements such as the abundant silicon (Si) are used as the chips’ substrate. When manufactured, impurities are deliberately added (a process called “doping”) to alter the conductivity characteristics, making them more suitable as electronic-device components. Common dopants are arsenic or boron, each with a different quantity of outer electrons that create positive or negative charges and electron “holes.” In a move away from electronic technologies such as vacuum tubes and crystal diodes in 1958, semiconductor components have allowed companies to continually

-

Posted: October 20, 2016Read more »

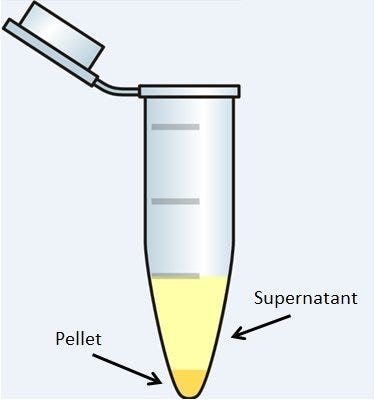

Centrifugation is one of the most widely used laboratory techniques for the separation of materials in the fields of biochemistry, molecular biology, medicine, food sciences and industry. It’s all about gravity and mass: particles in a heterogeneous solution will, given enough time, separate based on their size and density. Smaller, less-dense particles may also migrate down, but not always; some particles will never settle, but remain suspended in solution. Centrifuges force this process along much more quickly and efficiently. Its uses have proven to be so powerful and wide-spread across the sciences that centrifuges have been a common piece of laboratory equipment since the late 19th century.

-

Posted: October 03, 2016Categories: Furnishings & EquipmentRead more »

Cleanrooms are used to perform clean processes, so it’s counterintuitive to think of maintenance and repair activities inside a controlled environment. Yet, they are very necessary and performed quite often. Protocol for crews working inside a cleanroom is different than the typical office space: personnel must gown and adhere to strict clean processes, just like lab technicians. The equipment crews bring into the cleanroom must also be compatible with the required ISO rating. Slow, careful movements and meticulous control over dust and other contaminants are critical to prevent complete shut-down and time-consuming recertification of the room.