- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

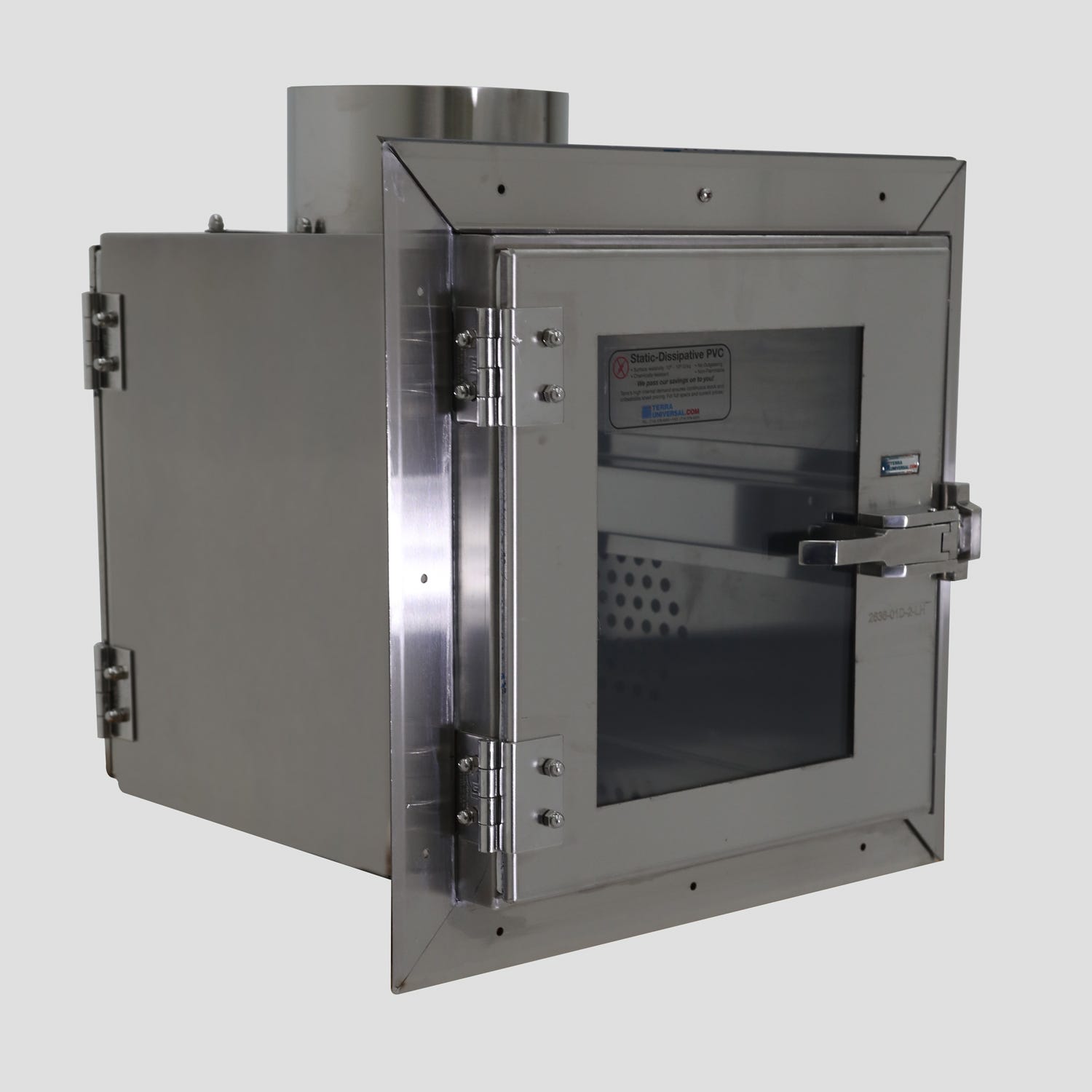

Terra's latest passthrough chamber designs feature a closed-loop HEPA filtration module and dozens of readily integrated smart features. In meticulously regulated industries, passthrough chambers with integrated HEPA filtration are essential for flushing stagnant air and maintaining low particulate within a transfer box enclosure.

Terra manufactures standard models of the HEPA-filtered pass-through chambers and can build fully customized solutions to fit any customer application.

Start browsing: HEPA/ULPA Filtered Pass-Through Chambers

Introducing people and objects to an atmosphere-controlled environment requires special considerations for contamination control. Without a passthrough chamber, an operator would need to enter and exit the cleanroom many times to retrieve, replenish, and deliver finished or raw goods. While passthrough chambers can address most logistical issues, additional measures are required to prevent dirty air from entering a clean environment, especially within negative pressure environments that also require aseptic workflow. Because transfer chambers are prone to spills and operator interaction, it's also important that the chamber components are easy to clean, free of cracks and crevices, and resilient against aggressive decontamination methods such as heat, radiation, or chemical sterilants.

A pass-through chamber with HEPA filtration ensures that air quality within the transfer box will not host pathogens or particulates. Continual purging and filtration of the chamber air ensures that air inside the passthrough remains as clean as air within the cleanroom.

Watch: Pass-Through Chambers for Aseptic Biological and Pharmaceutical Requirements

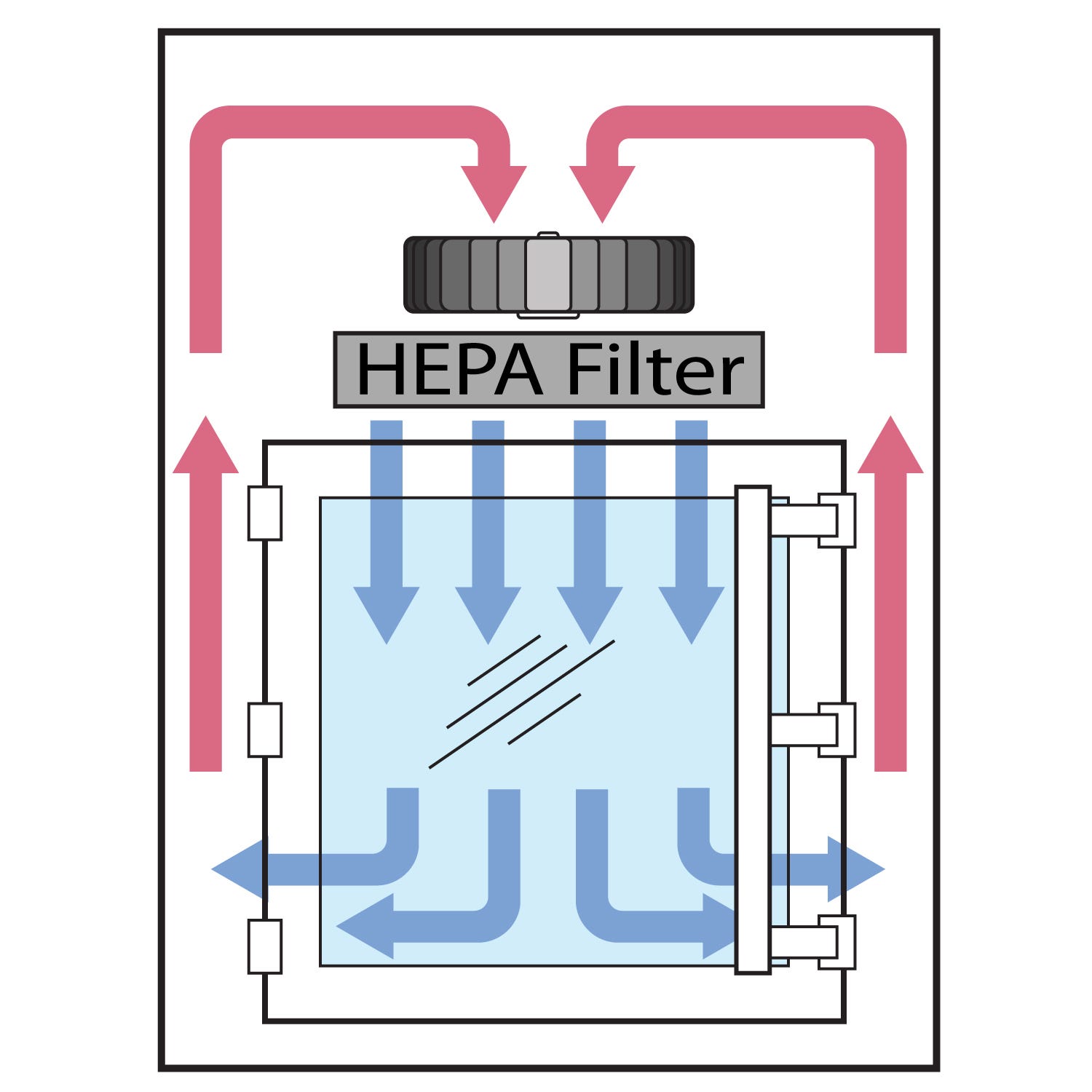

HEPA integrated cleanroom passthroughs enhance air quality and remove stagnant air when passing sterile preparations or biologically sensitive samples between two areas of different air quality classification. By recirculating the interior air, airborne particles are rapidly removed by successive passes through the HEPA filter. Recirculation also minimizes pressure buildup that can cause leakage into an adjacent positive-pressure cleanroom.

USP 800 and Hazardous Drugs

Like Terra’s other Smart pass-through chambers, the HEPA-filtered model includes an interlock mechanism with an alarm that prevents the doors on either side from opening at the same time. Not only does this prevent contamination from dirtier spaces, but it also prevents disruption of air balancing between rooms of differential pressure. As long as one side of the passthrough remains open, the other side will always remain locked.

A HEPA-filtered pass-through chamber is especially important for any USP 800 cleanroom that is also used for sterile preparations. Since a USP 800 cleanroom must be under negative pressure, the air inside the pass-through will be pulled into the cleanroom each time the door is opened. Recirculating HEPA filtration further minimizes the chance of introducing airborne contaminants via the pass-through chamber, particularly when the adjoining room is unclassified.

USP 797 Cleanrooms

A BioSafe® passthrough chamber with HEPA filtration is ideal for preparing pharmaceutical compounds including injectables, IVs, and other sterile preparations. The seamless interior makes daily cleaning and sterilizing much faster and easier. The filtered airflow also greatly reduces the amount of surface contamination that accumulates throughout the day.

316L stainless steel is easily sterilized and thus an ideal material for cleanroom pass through construction within sterile bio-pharma applications. The isolated interlock (hidden inside a double-wall design) simplifies cleaning and eliminates cracks that can harbor contaminants, making it ideal for life sciences and clinical applications. Removable doors facilitate rapid and repeatable sterilization which could otherwise only be achieved by aggressive chemical sterilants such formaldehyde, vaporized hydrogen peroxide (VHP), or other biocidal oxidizes.

For typical USP 797 cleanrooms, a larger passthrough window may be specified for supplies introduced from the buffer area, while a smaller passthrough chamber is suitable for passing completed preparations back to the ante-area where a pharmacist checks them.

Medical Devices and Sterile Packaging

Similar to sterile pharmaceuticals, these passthrough chambers are a great choice for medical device manufacturing during the production of T-cell therapy devices, catheters, sterile packaged items, pacemakers, and other biologically sensitive items. Integrated HEPA filters and add-on UVC decontamination lighting provides an additional level of contamination control as objects enter and leave the cleanroom through the transfer box. Optional barcode stock control systems enhance the speed and ease of receiving materials, maintaining stock levels, and allow immediate updates to the facility database.

Terra offers specialized HEPA-filtered pass-through chambers for installation in fire-rated walls. The fire-rated doors include insulated double stainless steel walls, wire-free construction, a fire-rated glass-ceramic viewing window that is also impact resistant. To maintain UL fire-rating certification, maximum fire-rated door dimensions not to exceed 30”W x 45”H.

Each time the passthrough chamber opens, the filtration system rapidly evacuates any contaminated air within the chamber and introduces fresh HEPA filtered air.

HEPA filtered air is standard for all cleanroom environments, as it isolates a product from airborne lint, fiber, particulate, or human borne contamination (hair, dandruff, dead skin cells). A closed loop system means that the air continuously recirculates through the HEPA filter. The transfer chamber will be slightly pressurized, but this may differ depending on the pressurization of adjacent rooms.

Models include either a mechanical or a fully electronic interlock system. The interlock device allows only one open door at a time, thus minimizing the amount of “dirty” air and cross-contamination that might otherwise encounter sensitive products or tooling.

A stainless steel screen protects the face of the HEPA filter and provides an easy-to-clean surface. The screen is held in place by double roller catches, which allow the screen to be easily popped out of the ceiling to replace the HEPA filter.

Air return slots along the bottom interior of the chamber circulate air back through the built-in fan and HEPA filter. The speed control knob allows adjustment of the blower RPM, increasing the airflow and pressure within the chamber.

The pressure gauge on the unit measures the backpressure at the filter, which can be used to monitor its efficiency and remaining filter life.

Related: Do I Need A Passthrough? Benefits of Cleanroom Passthrough Chambers

Standard Floor Configuration installs at the base of the wall and includes ramps for rolling carts and wheeled containers through.

Standard Wall Mount Configuration reduces the size footprint when space is limited.

The CleanMount® System is a clamping mechanism for installation without requiring piercing of the wall surface. This design enables quick installation with minimal impact on any high-grade finished surfaces. In this video, you can see that CleanMount installation is feasible in just a few minutes with minimal tools and does not require shutting down the cleanroom for installation. The CleanMount® System also disassembles quickly and cleanly while the cleanroom remains in operation.

Terra’s knowledgeable Product Specialists are available by phone, email or LiveChat to help select the best pass-through for your application: Contact Us!

The General-Use HEPA Filtered Pass-through offers a standard mechanical interlock and economical construction. These pass-throughs are designed to control particles, but should not be used for sterile/hazardous applications.

Terra’s Smart Pass-Through™ version features BioSafe® construction for aseptic environments and includes an integral Smart controller. The Smart controller allows the addition of electronic accessories such as UV sterilization, open/close LED indicator, load presence sensors, data-logging, and a host of high-tech security features.

Intercom System

Built-in intercom system lets users easily call and communicate between rooms. No more shouting or awkward sign language.

Automatic Passthrough Chamber Doors

Hands-free operation of the pass-through door, governed by the electronic interlock; automatically closes based on delay timer.

Watch: Terra Universal Automatic Passthrough Chambers Doors

Infrared Load Sensor

Infrared load sensor beams detect objects placed inside the transfer chamber; can be used to trigger an audible alert.

Iris Scanner

Fully automated iris scanner for secure, hands-free access (includes data logging and optional secondary keycard reader)

Fingerprint Scanner

Biometric fingerprint scanners prevent unauthorized access via shared keys or passwords while also providing data logging capability. An integrated proximity card reader enables two-factor authentication. access to the pass-through

Video Camera

An HD camera with a microphone continuously records during door-opening for remote monitoring within the transfer chamber.

UV-C Sterilization and LED lights

LED lights are recessed with a transparent lens for easy cleaning; UV-C module neutralizes microbes using a timed disinfection cycle.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Call (714) 459-0731