- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

A vacuum chamber is a sealed container that creates a localized, low-pressure environment. Vacuum chambers and vacuum gloveboxes are used in a variety of applications including scientific research, manufacturing, product development, performance testing, and simulation environments. Vacuum chamber applications include, but are not limited to, leak testing, stress testing, semiconductor failure analysis, degassing, drying, distillation, permeability testing, coating, specific gravity determination, atmospheric simulations, and inert gas storage.

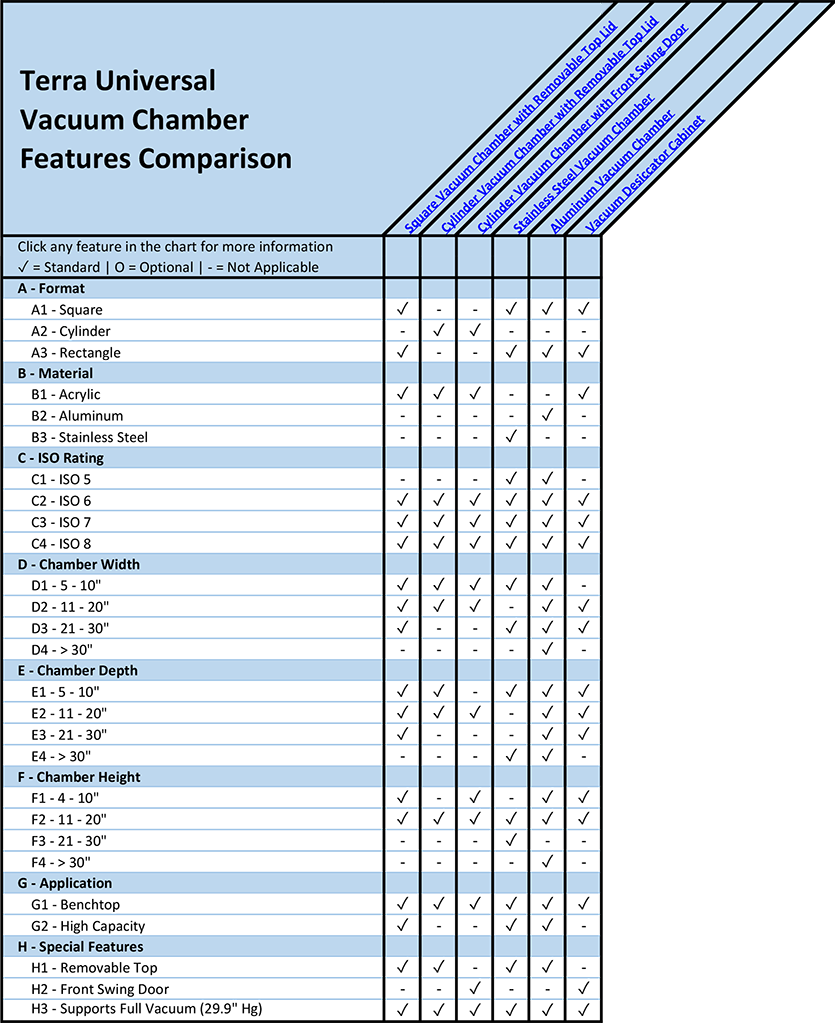

Terra manufactures its vacuum chambers in a variety of materials including acrylic, polycarbonate, aluminum, and stainless steel. Depending on the material type, size, and configuration, each type of vacuum chamber has its own set of unique features that are important for different applications, and unique to the needs of the end user. Importantly, end users must consider the size, volume, and geometry of the vacuum chamber to maximize the speed, ease, and efficiency of the task at hand.

Below, we'll discuss, compare, and contrast several vacuum chamber designs, types, and styles that will help you determine the best vacuum chamber solutions for your needs.

Square Vacuum Chambers maximize headroom to accommodate items with a broad footprint, while also having a larger internal volume and more uniform pressure distribution than cylinder vacuum chambers.

Terra's Cylinder Vacuum Chambers offer improved rigidity and minimize 90-degree corners, thus making them easy to clean and maintain. A smaller footprint makes them affordable and well-suited for smaller spaces. A smaller chamber volume makes for faster and more efficient vacuum cycling but offers the least amount of internal chamber space compared to square and rectangular versions.

Rectangular Vacuum Chambers maximize internal chamber space and have a larger internal volume than both cylinder and square vacuum chambers. Rectangular chambers offer a high degree of pressure uniformity and enable the processing of larger components or assemblies, especially those that are extra long or wide.

Acrylic Vacuum Chambers with Removable Top Lids support full vacuum to 29.9" Hg. Transparent 1" thick acrylic chambers feature stainless steel latches and an inlaid O-ring with a precision-routed channel to ensure uniform coverage and ultra-low leak rate.

Acrylic Adjust-A-Shelf™ Vacuum Desiccator Cabinets are made of acrylic and have 1" thick walls, which support full vacuum up to 29.9" Hg. The spacious vacuum chambers have front-swing doors, making it easy to access and transfer parts quickly. The shelf system is removable and adjustable, allowing for faster batch processing of smaller parts. Each unit is individually tested to hold full vacuum at 29.9"Hg with no detectable change for 72 hours. Additionally, the cabinets can be customized with feed-throughs for electrical connections inside the vacuum chamber.

Terra's Aluminum Vacuum Chambers are available in benchtop sizes for small and general items, or larger format high-capacity chambers for large and numerous items.

Benchtop units are as small as 9" x 9" x 9.5"

Floor-standing units are as large as 37" x 37" x 37.5".

Advantages of Aluminum Vacuum Chambers

Terra's Aluminum Vacuum Chambers offer an economical alternative to stainless steel chambers, while also offering better chemical and thermal properties than acrylic chambers. Aluminum offers enhanced chemical resistance when using disinfectants, such as isopropyl alcohol, or sporicidal agents.

Regarding thermal properties, aluminum vacuum chambers transfer heat quickly and efficiently, which can be essential for temperature-sensitive processes, such as thermal cycling. However, this characteristic also makes these chambers more sensitive to environmental drift via changes in ambient air temperature, or when placed nearby to heat-generating equipment.

Because aluminum is not magnetic, it can be beneficial for reducing interference when testing materials that generate magnetic fields, or to prevent damage to materials that are sensitive to electromagnetic fields.

Terra's 304 Stainless Steel Vacuum Chambers feature double-wall stainless steel chambers and vacuum levels down to 29.9" Hg. Stainless steel is preferable for sterile or aseptic environments that require frequent cleaning between cycles and are particularly well suited for degassing, curing plastics, processing chemicals, and removing moisture.

Stainless steel vacuum chambers are typically associated with precision testing and research environments that are sensitive to contamination and off-gassing. For example, semiconductor manufacturing, space simulation, surface analysis, and high-energy physics. In these sectors, minuscule amounts of molecular or particulate contamination may cause failures, defects, inaccurate results, and poor reproducibility.

The outgassing rate is an important consideration when selecting a vacuum chamber for certain types of tasks. Outgassing refers to the release of gases from the surfaces of materials when they are placed in a vacuum environment, which can interfere with the performance of sensitive equipment or contaminate samples being studied. A low outgassing rate means that fewer gases are released into the vacuum environment, which maintains a stable environment for experiments or other applications. Stainless steel chambers offer the lowest rates of off-gassing when compared to plastic chamber materials.

Effective cleaning processes alone can reduce outgassing rates by multiple orders of magnitude, therefore Terra's high-quality 304 stainless steel chambers are designed to make easy work of regular cleaning and bake-out cycles. Rated for ISO 5 cleanrooms, the smooth interior surfaces simplify cleaning and minimize edges and crevices that may harbor contamination. A double wall chamber includes an integrated, heat-resistant safety glass viewing window for viewing and monitoring.

As a cleanroom specialty manufacturer, Terra provides a deep selection of cleanroom-rated vacuum chambers, and each product is conveniently labeled with its respective cleanroom rating.

Terra often provides custom vacuum chamber solutions when a customer requires an atypical design, material, or configuration that must meet a specific ISO cleanliness rating. Terra can tailor the product to meet your rating and certify it with the part numbers appended to your invoice, which will be included in your compliance package.

Terra's Stainless Steel and Aluminum Vacuum Chambers offer ISO-rated cleanliness levels down to ISO Class 5, which are typically specified for ultra-hygiene applications.

Terra's Acrylic Plastic Vacuum chambers are ISO-6 cleanroom rated.

Terra's Acrylic Full-Vacuum Gloveboxes are rated for ISO 7 / ISO 8 cleanroom environments, which makes them suitable for moderate cleanliness requirements during anaerobic processing in a low-humidity nitrogen or argon environment.

Benchtop Vacuum Chambers offers a small-footprint vacuum chamber configuration for general applications, pressure testing, and cycle testing of small objects.

Large-Capacity Vacuum Chambers provide ample processing space for degassing large assemblies. An internal 18" wide shelf supports loads up to 75 pounds.

Terra's Acrylic Vacuum Chambers with Removable Top Lids feature a removable top lid that offers easy access to the interior of the chamber, which simplifies the loading and unloading of samples or equipment. Top-side removal lids are ideal for frequent changes or adjustments to the contents of the chamber, a common requirement for vacuum chamber testing, research, and manufacturing processes involving multiple stages, cycles, or iterations. The removable top lid allows for larger or irregularly shaped items to be placed inside the chamber, thus making them well-suited for industries including aerospace, electronics manufacturing, and materials science.

Terra's Cylindrical Vacuum Chambers with front-swing doors allow high-capacity storage, easy batch processing, and quick parts transfer. Optional feedthrough ports allow for the connection of electronics, probes, and sensors within the vacuum chamber. A Vacuum Control Module is important for vacuum testing or processing applications that require sustained and precisely regulated vacuum levels (besides full vacuum).

Terra Vacuum Chamber Systemsare capable of producing low pressure down to 29.9inHg. Beyond achieving a specific pressure target, it's also important to choose a vac chamber that can maintain that pressure range throughout the entirety of the cycle, which is required to support many different manufacturing and scientific pursuits including: Thin Film Deposition: used in the production of electronic devices, solar cells, and other applications to deposit thin films without interference from air molecules. Material Testing: simulate the conditions of outer space or high-altitude environments and study the effects of low pressure on materials in extreme conditions.

Electron Microscopy: create a low-pressure environment that allows electrons to travel freely without interference from air molecules, thus enhancing resolution when imaging materials or biological samples.

Thermal Processing: create a controlled environment for the heat treatment of materials during the production of semiconductors, ceramics, and other materials.

Leak Testing: low-pressure vacuum chambers allow the detection of leaks that are difficult to detect in normal atmospheric conditions.

Shop Terra's wide selection of in-stock benchtop vacuum chambers. Buy a vacuum chamber online, or chat with a live product specialist to discuss your unique requirements.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Call (714) 459-0731