- Available ISO Ratings: ISO 7, ISO 8

- Smart® gas-purge desiccator cabinet automates low-humidity control down to 0% RH

- Ideal for moisture-sensitive materials: microelectronics, medical devices, pharmaceutical powders

- Gas control system auto-adjusts nitrogen purge to maintain sub-ambient humidity set point

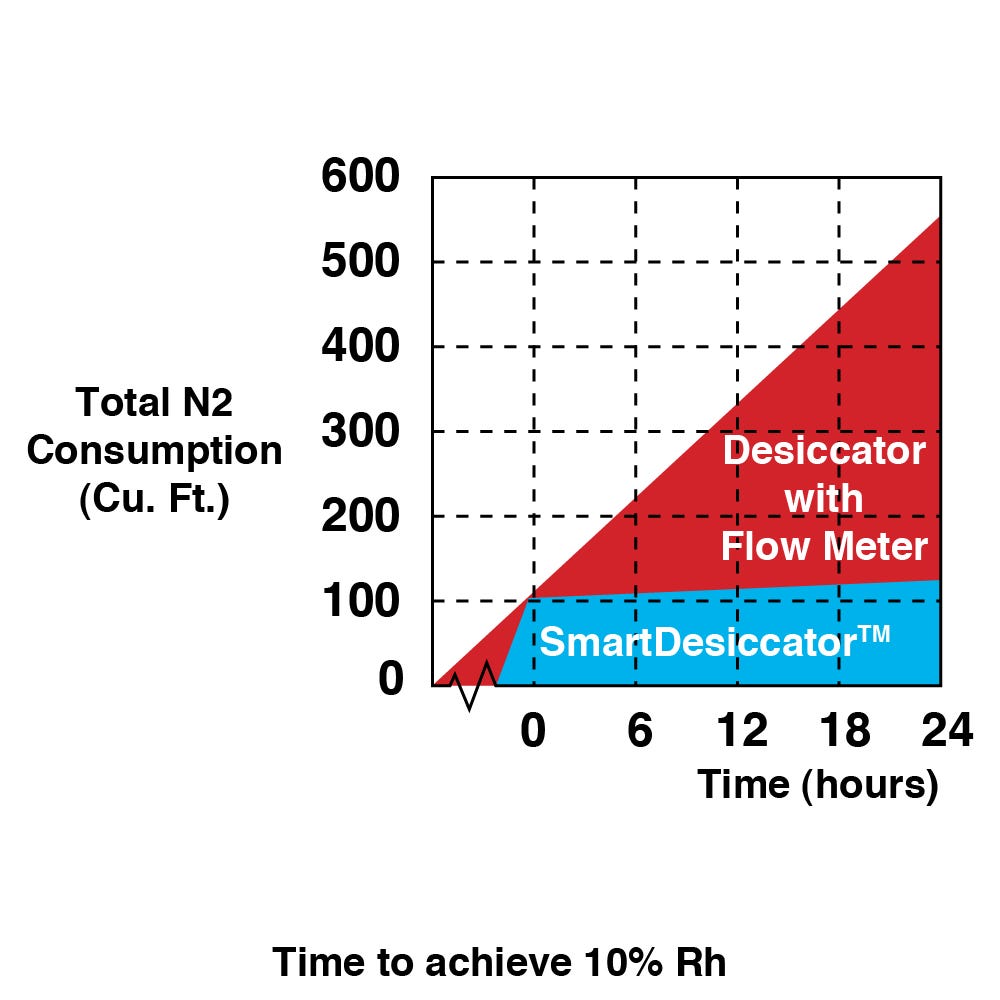

- Fast-acting and economical; maintains below 10% RH with 78% less nitrogen than manual flow meter

- Fully integrated turnkey system takes seconds to install and program

• Chamber Dimensions: 21.5" W x 20.5" D x 16.5" H

• Material: 304 Stainless Steel

• Opening Dimensions: 20.25" W x 14.5" H

• Number of Chambers: 1

• Model: Smart®

• Design: Benchtop

• Chamber Width: 21.5"

• Chamber Depth: 20.5"

• Chamber Height: 16.5"

• Humidity Control: Chamber Level

• Door Design: Leak Tight

• Unit of Measure: EA