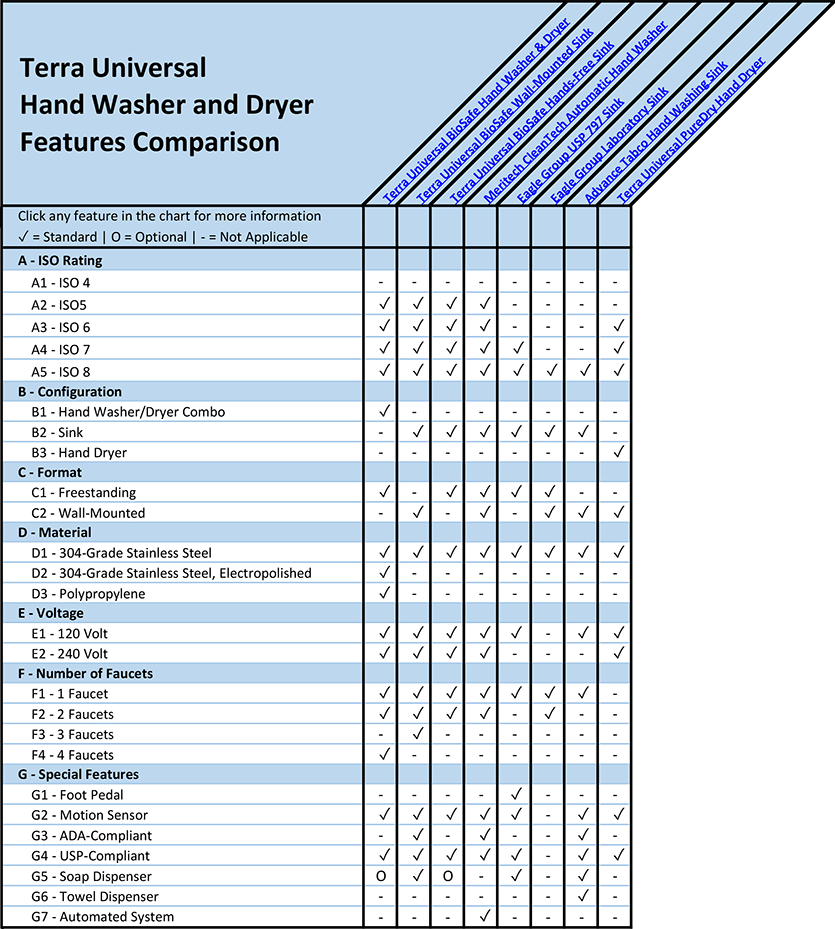

Compare Features: Cleanroom & Laboratory Sinks, Hand Washers, Hand Dryers

As humans are the primary source of contamination in cleanroom and lab environments, cleanroom-compliant hand washers, sinks and hand dryers play a critical role in reducing bioburden and viable particle counts within sterile spaces.

Cleanroom Sink Requirements

Several features, common to cleanroom-compliant sinks and hand dryers, support their use in critical environments. Sloped basins ensure efficient draining of water, protecting the lab from water spillage on work surfaces (which promote microbial growth and affect sample and reagent dilutions). Durable, rigid, 304-grade stainless steel construction resists common chemicals, alcohol-based cleaners, and disinfectants, preventing contamination stemming from rust or corrosion. Smooth surfaces promote easy wipe-downs, protecting the lab from particle aggregation in cracks and crevices. Hands-free mechanisms, such as foot pedals, motion sensors and infrared (IR) beams, inhibit surface-borne contamination from affecting experiments. Standard, food-grade sinks often do not include these features, placing their staff at risk of contaminating products, reactions and experimental results.

Terra’s portfolio of cleanroom hand washers, sinks and hand dryers includes several brands featuring an array of sanitization technologies and application-specific benefits.

BioSafe® cGMP Hands-Free Sinks and Drying Stations

Terra Universal’s offers an in-stock selection of BioSafe Sinks and Hand Dryer Stations that combine an IR-activated water faucet with two HEPA-filtered, air-blade hand dryers within a single system.

Ideal for aseptic cGMP labs, Terra’s BioSafe design features continuous-seam welds along the top perimeter of the station for an easy-clean surface free of cracks and crevices that harbor microbial growth. The combined hand washing and drying station eliminates the need for staff to move from the sink to a separate drying area, protecting the lab from water spillage. The whisper-quiet, mess-free Dyson air-blade dries hands in 14 seconds, improving staff scrub-in times. Within the BioSafe product line, Terra also manufactures wall-mounted, ADA compliant sinks, and modular, scalable pedestal sinks.

Cleanroom Hand Washing Stations

Meritech’s CleanTech Automatic Hand Washing Station provides a self-enclosed, touch-free, automated system to optimize employee hand hygiene. The system delivers a pressurized 12-second wash cycle to sterilize hands up to mid-forearm, including fingernails, palms, and fingertips. The CleanTech station automatically runs a self-cleaning cycle every 8 hours, flushing the system of harmful pathogens in the plumbing line.

USP-Rated Cleanroom Sinks for Pharmaceutical Compounding

Eagle Group’s USP <797> and <800> sinks comply with the U.S. Pharmacopeia standards for sterile hazardous and non-hazardous drug compounding. The pedestal sinks operate via two hands-free mechanisms – foot pedal or eye sensor – to prevent surface-borne contamination of compounded sterile preparations.

Medical Grade Sinks

Advance Tabco’s medical-grade hand washing sinks include soap and towel dispensers, deck-mounted or splash-mounted faucets, and basket drains to retard water spillage. Hands-free and ADA-compliant models are available.

Cleanroom Hand and Glove Dryers

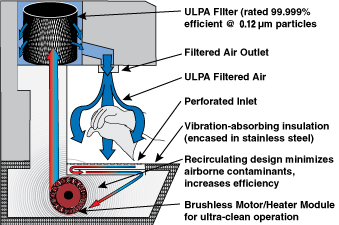

Terra Universal PureDry cleanroom hand and glove dryers (in-stock, ready to ship) supply warm, ULPA-filtered, contamination-free air to dry bare hands, gloved hands, medical devices, electronic components, and reagent bottles. Recirculating, wall-mounted models feature integral air returns and catch basins to prevent water spillage. The 304-grade stainless steel housing is free of cracks and crevices that harbor germs and non-viable contaminants.

A - ISO Rating

(back to chart)

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO 14644-1 provides guidance on monitoring and validating cleanroom conditions, establishing procedures for testing and evaluating air cleanliness, and ensuring ongoing compliance with the specified cleanliness levels.

Terra’s products are designed to comply with the below ISO 14644-1 classifications.

A1 - ISO 4

The maximum allowable concentration in an ISO class 4 environment is 10,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 4 cleanrooms, or enclosures, must maintain an average airflow velocity of 50 – 90 feet per minute and an average air change rate of 300 – 540 changes per hour.

A2 - ISO 5

The maximum allowable concentration in an ISO class 5 environment is 100,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 5 cleanrooms, or enclosures, must maintain an average airflow velocity of 40 – 80 feet per minute and an average air change rate of 240 – 480 changes per hour.

A3 - ISO 6

The maximum allowable concentration in an ISO class 6 environment is 1,000,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 6 cleanrooms, or enclosures, must maintain an average airflow velocity of 25 – 40 feet per minute and an average air change rate of 150 – 240 changes per hour.

A4 - ISO 7

The maximum allowable concentration in an ISO class 7 environment is 352,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 7 cleanrooms, or enclosures, must maintain an average airflow velocity of 10 – 15 feet per minute and an average air change rate of 60 – 90 changes per hour.

A5 - ISO 8

The maximum allowable concentration in an ISO class 8 environment is 3,520,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 8 cleanrooms, or enclosures, must maintain an average airflow velocity of 1 – 8 feet per minute and an average air change rate of 5 – 48 changes per hour.

B - Cleanroom Sink Configuration

(back to chart)

B1 - Hand Washer/Dryer Combo

Terra Universal’s in-stock selection of BioSafe Hands-Free Sink and Hand Dryer Stations combine an IR-activated water faucet with two HEPA-filtered, air-blade hand dryers within a single system. The combined hand washing and drying station eliminates the need for staff to move from the sink to a separate drying area, protecting the lab from water spillage.

B2 - Sink

Terra Universal’s BioSafe wall-mounted, ADA-compliant sinks and modular, pedestal sinks feature hands-free operation, rigid, durable 304-grade stainless steel construction and sloping drains to prevent water spillage. Meritech’s CleanTech Automatic Hand Washing Station provides a self-enclosed, touch-free, automated system to optimize employee hand hygiene. The system delivers a pressurized 12-second wash cycle to sterilize hands up to mid-forearm, including fingernails, palms, and fingertips.

Eagle Group’s USP <797> and <800> sinks comply with the U.S. Pharmacopeia standards for sterile hazardous and non-hazardous drug compounding. The pedestal sinks operate via two hands-free mechanisms – foot pedal or eye sensor – to prevent surface-borne contamination of compounded sterile preparations.

Advance Tabco’s medical-grade hand washing sinks include soap and towel dispensers, deck-mounted or splash-mounted faucets, and basket drains to retard water spillage.

B3 - Cleanroom Hand Dryer Features

Terra Universal PureDry cleanroom hand and glove dryers (in-stock) supply warm, ULPA-filtered, contamination-free air to dry bare hands, gloved hands, medical devices, electronic components, and reagent bottles. Recirculating, wall-mounted models feature integral air returns and catch basins to prevent water spillage. The 304-grade stainless steel housing is free of cracks and crevices that harbor germs and non-viable contaminants.

C - Format: Wall-Mounted vs Freestanding Cleanroom Sinks

(back to chart)

C1 - Freestanding Cleanroom Sinks

Freestanding cleanroom sinks offer simple connections to plumbing lines, easy access to change filters or clean reservoirs, and integral foot pedals for hands-free operation. In addition, pedestal sinks allow for installation in more locations than wall-mounted models. However, freestanding units encompass larger footprints and do not meet ADA guidelines.

C2 - Wall-Mounted Cleanroom Sinks

Wall-mounted cleanroom sinks meet ADA guidelines, include larger water basins, and take-up less floor space than freestanding systems. However, access to perform maintenance on the unit is often limited. Rather than foot pedal systems, hands-free models commonly include eye sensors or motion sensors. As wall-mounted units require wall cutouts, caulking and post-installation finishing, they are commonly specified during new lab builds rather than existing lab retrofit projects.

D - Cleanroom Sink Construction Requirements

(back to chart)

D1 - 304-Grade Stainless Steel Cleanroom Sinks

Durable, rigid, 304-grade stainless steel is resistant to a broad range of chemicals, hospital-grade disinfectants, and alcohol-based cleaners. Optimal for aseptic environments, 304-grade stainless steel resists corrosion and rust, but is more expensive than polypropylene.

D2 - Electropolished, 304-Grade Stainless Steel Cleanroom Sinks

Electropolished 304-grade stainless steel sinks are deburred and passivated to provide a cleaner, uniform aesthetic.

D3 - Polypropylene Cleanroom Sinks

Economical polypropylene is smooth, acid-resistant and capable of withstanding temperature fluctuations. However, polypropylene does not resist certain bleach-based, hospital-grade disinfectants.

E - Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States. 240-volt connections, common in Mainland Europe, require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

F - Single vs Multiple-Faucet Cleanroom Sinks

(back to chart)

Single-faucet units, like Advance Tabco’s Wall-Mounted Hand Washing Sinks, are designed for smaller research labs. For higher-throughput production labs with entire shifts of individuals scrubbing-in at the same time, multiple-faucet units, like Terra’s BioSafe Hands-Free Sink and Hand Drying Stations, help reduce staff gowning times.

G - Cleanroom and Laboratory Sink Special Features

(back to chart)

G1 - Foot Pedal Cleanroom Sinks

Hands-free pedestal units, like Eagle Group’s USP-Compliant Sinks, feature foot pedals to activate and alter the flow of water from the faucet.

G2 - Motion Sensor Cleanroom Sinks

Hands-free wall-mounted and freestanding units, like Terra’s BioSafe Hands-Free Sinks, feature infrared (IR) motion sensors to turn on and off the flow of water from the faucet.

G3 - ADA Compliant Cleanroom Sinks

ADA-compliant cleanroom sinks, like Terra’s BioSafe Wall-Mounted ADA Sinks, include a sloped drain board to provide space underneath the basin for wheelchair access.

G4 - USP Compliant Cleanroom Sinks

Eagle Group’s USP 797 and USP 800 cleanroom sinks comply with the U.S. Pharmacopeia standards for sterile hazardous and non-hazardous drug compounding. The pedestal sinks operate via two hands-free mechanisms – foot pedal or eye sensor – to prevent surface-borne contamination of compounded sterile preparations.

G5 - Cleanroom Sinks with Soap Dispensers

Several sink designs include integrated or optional, mechanical or hands-free soap dispensers mounted adjacent to the faucet.

G6 - Cleanroom Sinks with Towel Dispensers

Advance Tabco’s medical-grade hand washing sinks include soap and towel dispensers, deck-mounted or splash-mounted faucets, and basket drains to retard water spillage.

G7 - Automated Cleanroom Hand Washing Systems

Meritech’s CleanTech Automatic Hand Washing Station provides a self-enclosed, touch-free, automated system to optimize employee hand hygiene. The system delivers a pressurized 12-second wash cycle to sterilize hands up to mid-forearm, including fingernails, palms, and fingertips. The CleanTech station automatically runs a self-cleaning cycle every 8 hours, flushing the system of harmful pathogens in the plumbing line.

Shop and Compare Cleanroom Sinks, Hand Washers, and Hand Dryers Online

Visit Terra Universal Online to compare, configure, and get pricing for thousands of in-stock and ready-to-ship cleanroom sinks, dispensers, equipment, and furnishings. For over 40 years, Terra Universal has served the life science, pharmaceutical, biotechnology, and medical device markets.

Browse a wide selection of cleanroom sinks, hand washers, hand dryers, and hand washing stations. Contact a Terra sales specialist via phone, live chat, or email for help with configuration, large purchases, and application expertise.

Terra Sales and Customer Service

Mon - Fri, 09:00 AM - 08:00 PM PST

Tel: +1 (714) 578-6100

Email: [email protected]

Can't find what you're looking for?Tell us what you need and we'll build it!

.png)