Learn More: Modular Cleanroom Designs

Modular Cleanroom Selection Guide

Not sure what you need? Our Consultation Experts can help! Click here to specify your application requirements and receive a quotation within 24 hours.

Hardwall or Softwall Cleanrooms Full-View Plastic Panel

All-Steel BioSafe® Modular Cleanrooms

Hardwall Cleanrooms — Select transparent acrylic*, dissipative PVC, polycarbonate, or polypropylene panels. All-steel support frame for strength and easy installation - requires no external bracing.

*Acrylic is damaged by alcohol and other cleaning agents.

Softwall Cleanrooms — Many panel options, including anti-static vinyl and clear or frosted strip shields. All-steel supports available with casters. Softwall rooms do not hold pressure.

The most effective design for bio-tech and pharmaceutical applications.

304/316 stainless or powder-coated steel construction resists most solvents, disinfectants and other cleaning solutions. Radius corners and smooth interior walls simplify cleaning; optional raised flooring allows disinfectant wash-down. Configure as a positive- or negative-pressure room, with A/C and humidity control.

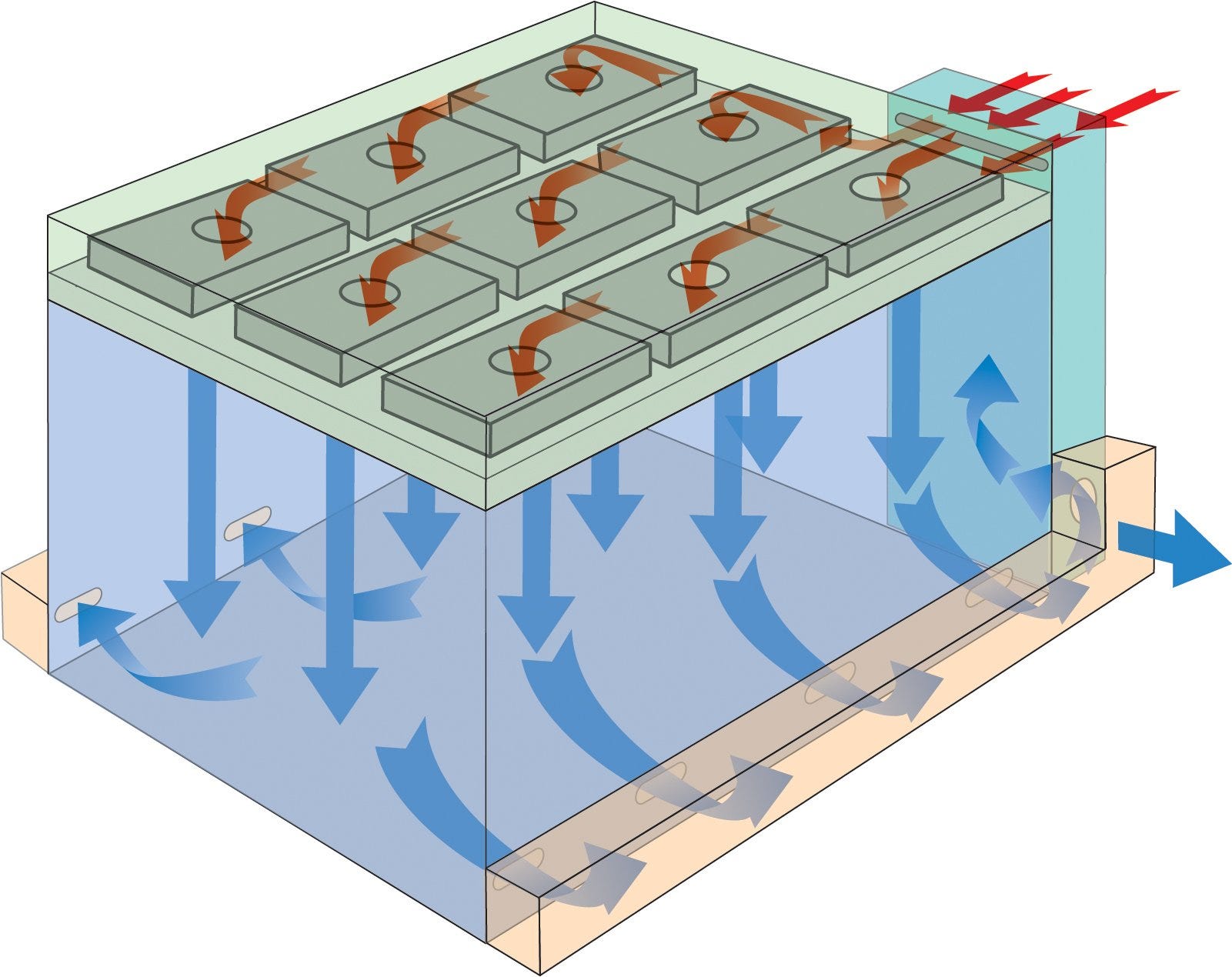

Double-Wall, Raised-floor Plastic Cleanrooms

Ventilation Cleanroom

Ideal for applications that require raised flooring for true laminar flow. Double-wall structure allows air to circulate through the inter-wall plenum, increasing filtration and A/C efficiency.

Ideal for safe removal of fine powders or chemical vapors. Adjustable ceiling ventilator draws air through HEPA filters and/or exhaust ductwork on ceiling or room perimeter. Inlet filters ensure a clean working environment.

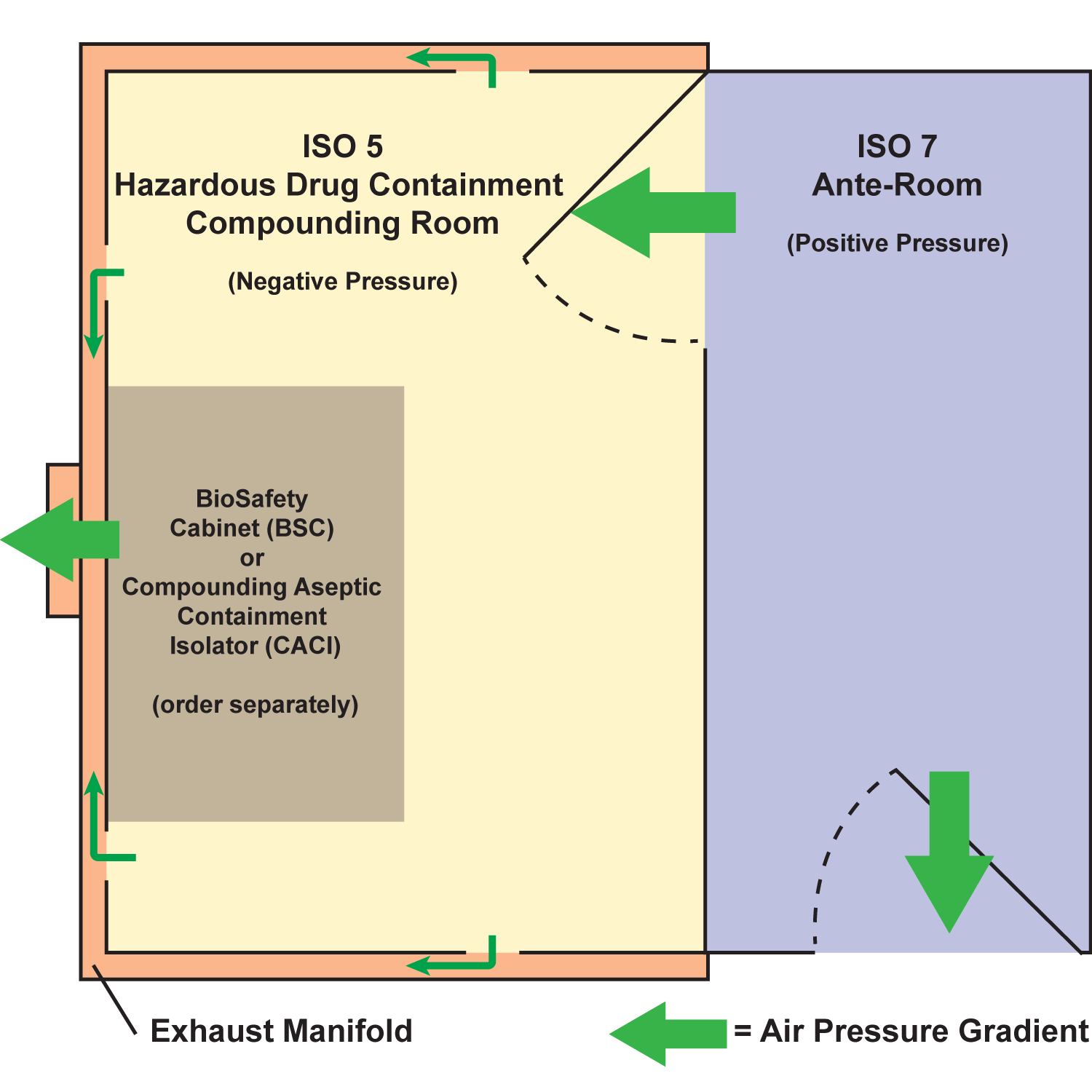

Sterile Compounding Rooms

Negative-Pressure Cleanrooms

In USP 797 applications, positive-pressure ISO 8 anteroom opens to an ISO 7 compounding room. For hazardous drug compounding to USP 800 requirements, air handlers remove HEPA-filtered air to produce a negative-pressure containment area. ISO upgrades meet more rigorous DQSA 503(b) requirements.

Ceiling fan/filter units create laminar flow of particle-free air. Exhaust ductwork along the floor and adjustable air handlers create overall negative pressure to protect external environment from pharmaceutical powders and biohazards.

Terra Universal's Value Advantage

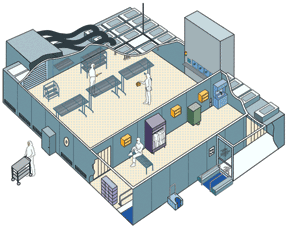

Facility Optimization — Create the production environment you require without the expense or disruption of a major fab upgrade! Expand or reconfigure as your requirements change.

Unsurpassed Cleanliness — Filtration and ventilation efficiency required to meet the most rigorous cleanliness standards. Independently certified Class 1.

Hardwall, Softwall, and AirLock Designs — A style for every requirement, schedule, and budget!

Comprehensive Environmental Controls — Over particulates, humidity, temperature, and ESD (electrostatic discharge)

Industry-leading Quality — Over 40 years of engineering and manufacturing experience provide standardized quality you can count on.

Certified Designs and Fabrication Techniques — Terra Universal has received independent certification as a Cleanroom Manufacturing Specialist.

Delivered to Your Production Schedule — Terra Universal understands the critical importance of timely delivery and works closely with you to accommodate tight schedules. Expanded QuickShip configurations provide a wide variety of "need it now!" cleanrooms.

Turnkey Purchasing: Terra universal's Value Advantage

No one shopping for a car would think of sourcing out the thousands of automobile components separately. Why should it be any different with a Modular Cleanroom?

Terra Universal's integrated design and manufacturing know-how lets you specify not just a clean work environment, but a total production solution:

- Application-Appropriate Environment—Over 20 years of design and manufacturing experience in all areas of environmental control: particles, humidity, static, temperature.

- Work Stations—ergonomic, space-saving, ultra-clean designs, including laminar flow and exhaust purification systems.

- Storage Solutions—from wall-mount and benchtop dry boxes to high-volume automated stockers.

- Gowning Area Furnishings—from the recognized industry leader in change room design and garbing protocol.