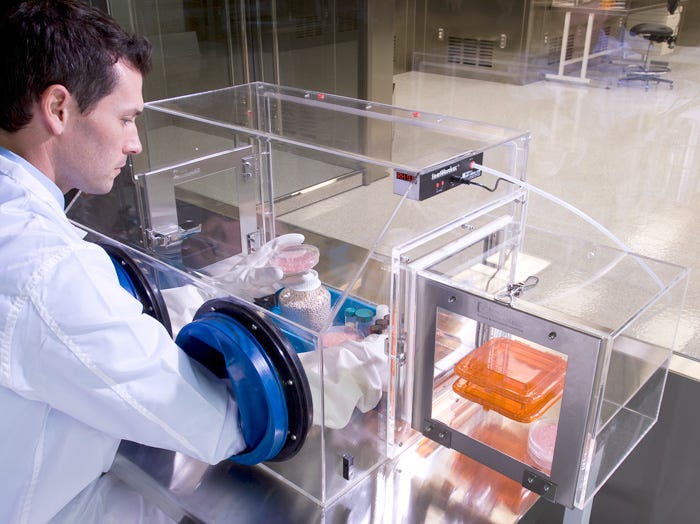

Learn More: Smart Glovebox

Smart™ Glovebox

- Humidity set point controls

- %RH display

- Choice of six materials, including 304/316L SS and dissipative PVC

- Automatic RB Valve

- 9" (229 mm)-diameter glove ports (order desired gloves separately)

- Airlock (optional)

- Stainless steel model comes with fluorescent illuminator

- Nitrogen Generator (not shown)

- Automates low-humidity processing to prevent degradation of moisture-sensitive parts

- Gas control system auto-adjusts nitrogen purge to maintain humidity set point

- Ideal for work with semiconductor components, medical devices and pharmaceutical powders

- Fully integrated turnkey system takes seconds to install and program

Positive Pressure Isolation vs. Biohazard Containment

Terra glove boxes are designed as positive-pressure isolation chambers that operate with a continuous inflow of process gas and include bleed valves to relieve overpressures. Unless specified, they are not designed as low-leak or air-tight containment chambers, nor should they be used with hazardous substances that require air-tight seals. In containment applications, a glove box should typically be operated under continuous negative pressure, via a ventilated duct, so that any small leaks do not contaminate the operator or the environment.

Terra Universal's Smart™ Glovebox automatically maintains a low-humidity environment to protect moisture-sensitive parts.

Its quick-response feedback system continuously monitors the chamber’s relative humidity level and indicates the measured value on a bright LED display.

The minute the %RH climbs above a set point value, the Smart™ Glovebox activates a flow of dry nitrogen for as long as needed to restore the desired humidity level.

This fast-acting control system economizes on nitrogen use. Comparison testing reveals that the Smart™ Glovebox maintaining a 10% RH level uses only 22% of the nitrogen required by a flowmeter-based system of identical size. More importantly, this automated operation maintains the integrity of sensitive parts, such as semiconductor chips, medical devices or pharmaceutical powders, without operator monitoring.

For optimal performance, select a pass-through air lock, which functions as a transfer buffer zone.

The Smart™ Glovebox includes a control system, Automatic RB valve, and inlet/outlet fittings for 0.25" (6 mm)-diameter gas line. A removable back wall allows introduction of large process equipment. Select air lock, work surface and gloves separately.