Learn More: eVAC Altitude Simulation Controller

eVAC™ Altitude Simulation Control Module

- Terra’s acrylic vacuum chambers can be used to simulate altitude very reliably by altering absolute pressure.

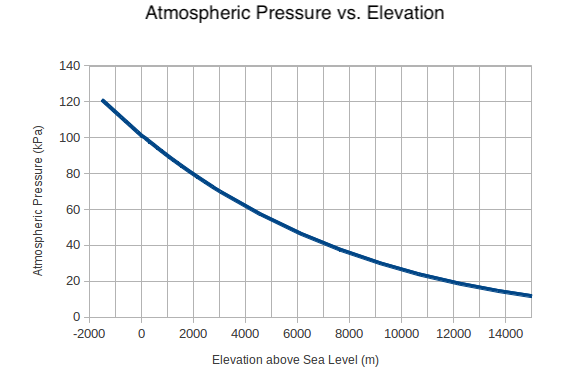

- Air pressure is a function of elevation – the higher the altitude the lower the pressure.

- Enter your kPa set point on control module to achieve corresponding altitude simulation required.

- The clear acrylic construction enables full view of the interior during testing.

Why is this applicable?

This is a very real packaging concern because the drop in atmospheric pressure induces pressure differences between the package and the shipper, resulting in shipping damage to the product.

The issue of altitude usually manifests itself by affecting package integrity. The ASTM 6653 test procedure, the standard test used to determine how the effects of higher altitude will affect package integrity, should be implemented on all packages.

Common applications include simulating package failures during transport of foods in high altitude, its effects on design of electronic devices since air is used as an electric insulating medium, aerospace industry testing to ensure their products can endure pressure changes with space travel, and the cosmetic industry’s need for testing due to different levels of intense sensitivity in consumers.

Why so Thick and Heavy?

Although your application may not require vacuum levels to 29.9"Hg, Terra builds its chambers to support this vacuum level due to safety concerns.

Variations in operators and operating protocol may lead to inadvertent spikes in vacuum pressure. Because these chambers are small, a few moments of vacuum operation beyond your target vacuum can subject them to substantially higher stress than you intend. Even a safety release switch is no guarantee that a chamber won't experience high vacuum pressure since these valves are not tamper-proof.

The best way to guarantee the safety of your parts and personnel is to use a chamber designed to sustain high vacuum levels. That's why Terra fabricates these chambers of 1" thick acrylic.

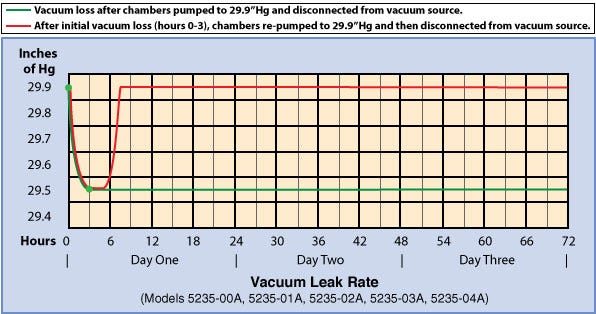

Vacuum Leak Test, 0-72 hours

Chambers lose vacuum pressure initially due to air released from acrylic walls during first three hours. If vacuum level of 29.9"Hg is restored following this initial drop in vacuum pressure, chambers hold 29.9"Hg with no detectable change in pressure over duration of test.

Aluminum vs. Plastic

- Acrylic Chambers

- Economy: Lower material cost translates into a less expensive chamber.

- Full visibility: You can add windows to an aluminum chamber, but nothing beats the 360-degree visibility offered by acrylic.

- Aluminum Chambers

- Chemical resistance: Aluminum stands up to Spor-Klenz®, alcohol and other sterilants, making it preferable in many bio/pharmaceutical applications. In addition, because many joining and sealing compounds are designed for use with metals, they may degrade acrylic and result in leaks or chamber failure.

- Greater machining versatility: Aluminum allows easier addition of feed-throughs to accommodate power and data cords, electrodes and other accessories. These add-ons are more feasible on aluminum than acrylic chambers, which are more prone to cracks that develop into leaks over time. For such applications, an aluminum chamber is a wiser long-term processing solution.

- More effective moisture barrier: Acrylic, because it is hygroscopic, allows moisture penetration on a molecular level. Under vacuum, these water molecules are released from the surface and may require several vacuum cycles to remove. These issues don’t occur with aluminum and other metallic moisture barriers.

- Greater dimensional versatility: Due to greater strength, aluminum is more appropriate than acrylic for larger chamber sizes.