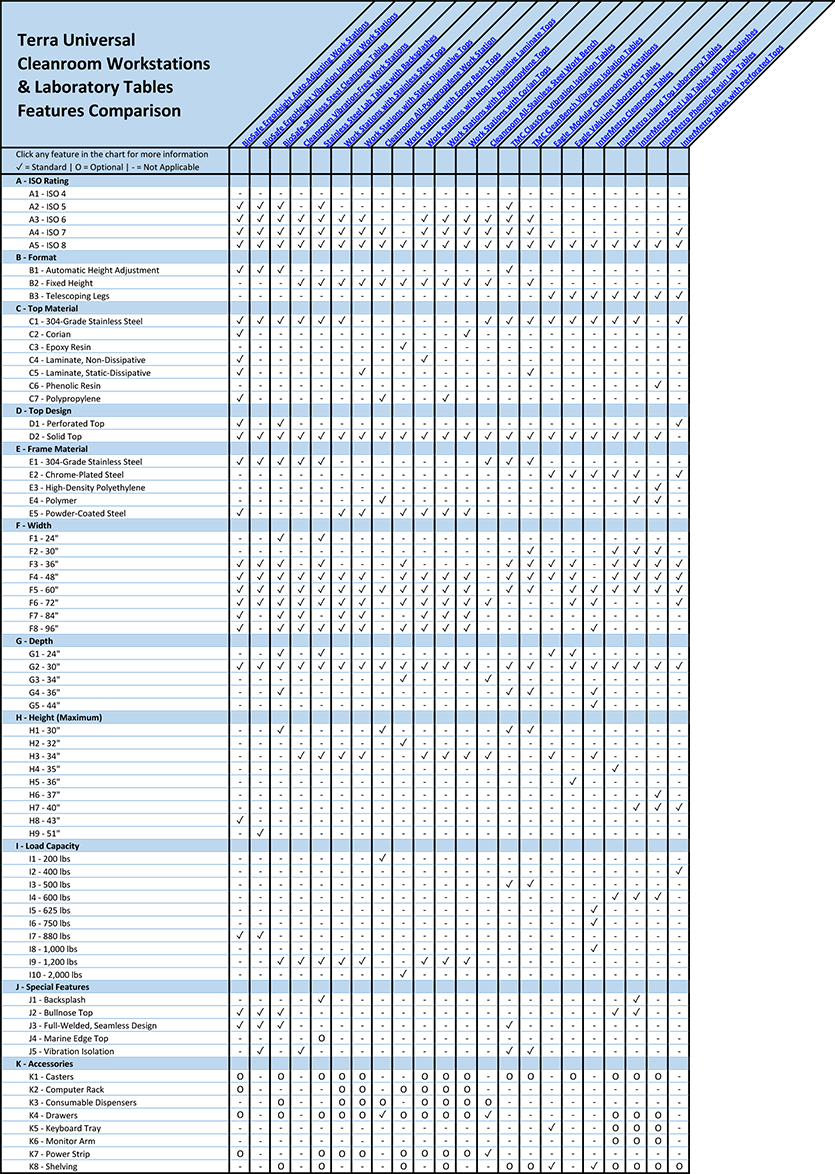

Terra Universal manufactures application-specific cleanroom workbench packages for a variety of uses, many available for immediate shipment and delivery from its Fullerton, California facility.

Terra also offers a wide selection of cleanroom specialized equipment from the following manufacturers:

Eagle (on-budget cleanroom tables and storage)

Metro (gowning furniture, modular tables, keyboard trays, monitor arms & drawers)

TMC (pneumatic vibration-isolated tables)

View All Cleanroom Workstations and Tables

A - ISO Rating

(back to chart)

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO 14644-1 provides guidance on monitoring and validating cleanroom conditions, establishing procedures for testing and evaluating air cleanliness, and ensuring ongoing compliance with the specified cleanliness levels.

Terra’s products are designed to comply with the below ISO 14644-1 classifications.

A1 - Iso 4

The maximum allowable concentration in an ISO class 4 environment is 10,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 4 cleanrooms, or enclosures, must maintain an average airflow velocity of 50 – 90 feet per minute and an average air change rate of 300 – 540 changes per hour.

A2 - Iso 5

The maximum allowable concentration in an ISO class 5 environment is 100,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 5 cleanrooms, or enclosures, must maintain an average airflow velocity of 40 – 80 feet per minute and an average air change rate of 240 – 480 changes per hour.

A3 - Iso 6

The maximum allowable concentration in an ISO class 6 environment is 1,000,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 6 cleanrooms, or enclosures, must maintain an average airflow velocity of 25 – 40 feet per minute and an average air change rate of 150 – 240 changes per hour.

A4 - Iso 7

The maximum allowable concentration in an ISO class 7 environment is 352,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 7 cleanrooms, or enclosures, must maintain an average airflow velocity of 10 – 15 feet per minute and an average air change rate of 60 – 90 changes per hour.

A5 - Iso 8

The maximum allowable concentration in an ISO class 8 environment is 3,520,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 8 cleanrooms, or enclosures, must maintain an average airflow velocity of 1 – 8 feet per minute and an average air change rate of 5 – 48 changes per hour.

B - Adjustable and Fixed Height Workstation Formats

(back to chart)

B1 - Automatic Height Adjustment Workstations

Terra’s BioSafe® ErgoHeight™ Adjustable Cleanroom Workstations allow the user to easily alter the viewing position between multi-shift operations or amidst changing workflow requirements. An on-board controller includes 4 saved height settings for quick and easy adjustment.

B2 - Fixed Height Workstations

Fixed-height cleanroom and lab tables are available with a weight capacity ranging between 1,000 - 2,000lbs.

Heavy-duty BioSafe® tables are rated to 1,200lbs and 3X tested at 3,600lbs for additional safety. Fixed height cleanroom tables ship fully assembled after being pre-packaged in a cleanroom. As described, these tables arrive with fixed legs and the surface height cannot be adjusted.

B3 - Telescoping Legs

Workstations with telescoping legs allow as-needed adjustment of the work surface height. Telescoping legs enhance ergonomics, reduce shipping cost, integrate with existing tables or casework, and support multiple operators who require different work surface heights. Each telescoping workstation is tested to ensure a weight load of 1,200lbs.

C - Cleanroom Work Surface Top Material

(back to chart)

C1 - 304-Grade Stainless Steel

Terra Universal designs and manufactures stainless steel table top workstations that combine durability, chemical-resistance, cleanliness, and conductivity.

304 stainless steel surfaces are an industry standard for cleanroom and laboratory environments. Stainless steel is compatible with most chemicals, resists oxidation, and cleans easily.

Terra's BioSafe® workstations minimize gaps and crevices known to harbor microbial, particulate, and residual contamination.

C2 - Corian Workstation Surfaces

Corian workstation surfaces are non-porous, 0.5" -thick table tops that discourage bacteria and mildew growth. The smooth surface is chemical-resistant and easy to wipe down. Beneficially, corian is a non-toxic hybrid composite formulated with acrylic resin and natural minerals.

C3 - Epoxy Resin Workstation Surfaces

Epoxy resin table tops are self-extinguishing, non-absorbent and corrosion-resistant. Fungal and bacterial resistant properties make these surfaces ideal for use in high-volume biochemistry labs and proteomic research.

C4 - Laminate, Non-Dissipative Workstation Surfaces

Terra's non-dissipative laminate cleanroom workstations cleanrooms or laboratories. Sealed laminate tops are compatible with ISO 5 (Class 100) cleanrooms and resistant to most solvents and hot solder.

Note: Laminate work surfaces are not designed for use with mineral acids.

C5 - Laminate, Static-Dissipative Workstation Surfaces

Terra's static-dissipative cleanroom workstations are optimal for static-sensitive materials that can be degraded or destroyed by the charges conducted by conventional benchtops. When made from inherently static-dissipative polyurethane, the result is a permanent, humidity-independent ESD protected surface for sensitive manufacturing conditions.

C6 - Phenolic Resin Workstation Surfaces

Phenolic resin cleanroom tables are chemical compatible and resistant to corrosion, abrasion and impact damage.

C7 - Polypropylene Workstation Surfaces

Polypropylene cleanroom surfaces resist a wide range of acids and caustic materials.

D - Workstation Surface Design

(back to chart)

D1 - Perforated Top Cleanroom Tables

Perforated top workstations allow laminar flow air to pass through the top surface and promote the passage of dirty air back to floor or wall mounted air returns. The design reduces air flow obstruction on critical surfaces and mitigates the occurrence of resuspended particles caused by eddies or turbulence.

D2 - Solid Top Workstations

Terra's solid top cleanroom and laboratory surfaces are easy to clean, sturdy, and well suited for research involving microtubes, vials, and ampules.

E - Workstation Frame Material

(back to chart)

E1 - 304-Grade Stainless Steel Workstation Frames

304 stainless steel workstation frames and work surfaces support easy disinfection, wipedown, and sterilization methods required for medical device or biotechnology use.

E2 - Chrome-Plated Steel Workstation Frames

Chrome plated steel is highly aesthetic, economical grade material that is both affordable and well-suited for a wide variety of dry storage and processing areas.

E3 - High-Density Polyethylene Workstation Frames

High-density polyethylene (HDPE) is a durable, lightweight thermoplastic with impact-resistant qualities and moderate chemical compatibility.

E4 - Polymer Workstation Frames

Polymer table frames offer a strong, lightweight frame design made of chemical-resistant polymer.

E5 - Powder-Coated Steel Workstation Frames

Terra’s signature white powder coat finish provides a high quality, durable barrier to protect against corrosion, plus a clean and attractive aesthetic. The advanced heat-fused formulation exceeds ASTM and ISO paint standards to resist chipping, scratching, fading, and wearing.

F - Cleanroom Workstation Width

(back to chart)

F1 - 24"

F2 - 30"

F3 - 36"

F4 - 48"

F5 - 60"

F6 - 72"

F7 - 84"

F8 - 96"

H - Cleanroom Workstation Height (Maximum)

(back to chart)

H1 - 30"

H2 - 32"

H3 - 34"

H4 - 35"

H5 - 36"

H6 - 37"

H7 - 40"

H8 - 43"

H9 - 51"

I - Cleanroom Workstation Load Capacity

(back to chart)

I1 - 200 lbs

I2 - 400 lbs

I3 - 500 lbs

I4 - 600 lbs

I5 - 625 lbs

I6 - 750 lbs

I7 - 880 lbs

I8 - 1,000 lbs

I9 - 1,200 lbs

I10 - 2,000 lbs

J - Special Workstation Features

(back to chart)

J1 - Workstation Backsplash

Cleanroom workstations with backsplashes help contain liquids, splatter, and spills from penetrating difficult to clean areas behind the workstation.

J2 - Bullnose Top Tables

Terra's one-piece bull-nose rounded edges increase operator comfort and reduce particulate shedding caused by sharp or abrasive edges. The smooth, continuous-seam welds also eliminate cracks and crevices that can harbor contaminants.

J3 - Full-Welded, Seamless Design

Fully-welded, seamless construction minimizes cracks, gaps, and crevices that may otherwise harbor microbes, particulate, and residual debris.

J4 - Marine Edge Table Tops

Seamless marine-edge work surfaces subdue spills and splashes when handling liquids and chemicals.

J5 - Vibration Isolation Workstations (Anti Vibration Lab Tables)

Vibration isolation workstations are ideal for housing sensitive instruments including microscopes, semiconductor inspection equipment, and automated lithographic exposure workflows.

Humans can sense vibration at a rate of 200 um/sec when performing microscopy work. Whether obvious or impalpable, environmental disturbances during magnified observation and inspection can cause operators to experience discomfort or sickness. Visual blur, which is caused by viewing vibrating objects under high magnification, is a typical contributor to nausea, dizziness, headaches, and fatigue.

Terra's ClassOne™ Cleanroom Vibration Isolation Tables feature Gimbal Piston isolators that eliminate up to 99.9% of floor vibrations caused by traffic, footfall, air handling equipment, and other conditions.

Terra's TMC CleanBench™ Vibration Isolation Tables with Gimbal Pistons achieve very low horizontal and vertical isolation input levels for loads up to 500lbs.

Learn More: Vibration Isolated Tables & Workstation Guide

K - Workstation Accessories

(back to chart)

K1 - Workstation Casters

Cleanroom workstation casters are easily retrofitted for mobility. Products can be rolled out of the way when cleaning or relocated as workflow changes.

K2 - Workstation Computer Racks

Workstation computer racks allow for easy, neat, and non-intrusive integration of workstation mounted PCs. The space-efficient rack mounts below the workstation surface and is constructed of powder-coated stainless steel for strength and cleanliness.

K3 - Consumable Dispensers

Integrated workstation dispensers are configurable for a wide variety of PPE, packaging materials, garments, and cleaning supplies. Integrated dispensers expand on-location storage capacity while also keeping stocked supplies neat and tidy.

K4 - Workstation Drawers

Optional workstation drawers are available in either plastic or stainless steel with many sizes and drawer configurations.

K5 - Workstation Keyboard Tray

Underdesk keyboard trays promote ergonomics and easy access. Trays support easy cleaning and mouse placement on either the left of right of the keyboard.

K6 - Workstation Monitor Arms

Workstation monitor arms are available in single and dual configurations. Heavy duty for flat monitors allow up to three pivot points and a clamp mount for a variety of table thicknesses.

K7 - Workstation Power Strip

Terra's integrated workstation power strips are UL-listed, surge protected, and available pre-installed from the factory.

K8 - Workstation Shelving

Terra Universal is a factory-direct distributor for Metro and Eagle shelving products, racks, fixtures, and accessories.

Need Help with Product Configuration?

Shop Terra Universal products online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra sales specialist via phone, webchat, or email for help with configuration, large purchases, and application expertise.

Shop Cleanroom and Laboratory Workstations by Brand

Can't find what you're looking for?Tell us what you need and we'll build it!

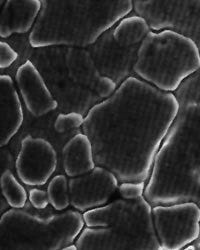

This photomicrograph represents the surface of 304 stainless steel with a No. 2B mill finish before Electropolishing. Note that the etched boundaries between the grains are only partially sealed, resulting in a network of sub-surface crevices. Contaminants that lodge in these crevices are protected from contact with cleaning agents leading to subsequent migration of trapped contaminants onto the cleaned surface.

This photomicrograph represents the surface of 304 stainless steel with a No. 2B mill finish before Electropolishing. Note that the etched boundaries between the grains are only partially sealed, resulting in a network of sub-surface crevices. Contaminants that lodge in these crevices are protected from contact with cleaning agents leading to subsequent migration of trapped contaminants onto the cleaned surface. This photomicrograph represents the same No. 2B surface after Electropolishing. Note that the surface is now completely featureless on a microscopic level and has the desired noncontaminating, non-particulating and non-sticking properties.

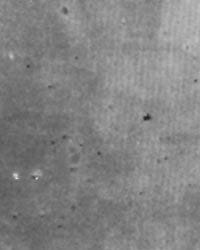

This photomicrograph represents the same No. 2B surface after Electropolishing. Note that the surface is now completely featureless on a microscopic level and has the desired noncontaminating, non-particulating and non-sticking properties. This photomicrograph represents a 304 stainless steel surface with a mechanically polished No. 4 mill finish before Electropolishing. Note the deep grooves, cavities, torn metal and other microscopic imperfections that entrap and retain contaminants.

This photomicrograph represents a 304 stainless steel surface with a mechanically polished No. 4 mill finish before Electropolishing. Note the deep grooves, cavities, torn metal and other microscopic imperfections that entrap and retain contaminants. This photomicrograph represents the same No. 4 finish after Electropolishing. The surface may still show some of the abrasiveproduced topography to the naked eye, but will now be microscopically featureless with the desired non-contaminating, non particulating and non-sticking properties.

This photomicrograph represents the same No. 4 finish after Electropolishing. The surface may still show some of the abrasiveproduced topography to the naked eye, but will now be microscopically featureless with the desired non-contaminating, non particulating and non-sticking properties.