Process Control, Safety, and Consistency

Polypropylene

- Economical plastic with broad chemical compatibility

- Ideal for wet processing station panels

- Loses some chemical resistance at high temperatures

- Suitable for HF and KOH processes

Quartz

- The preferred material for ultra-pure applications

- Provides greater uniformity in heat transfer than plastic baths—ideal for very tight temperature control

- Suitable for most chemicals (but not HF acid)

- Hard surfaces won’t scuff, stain, or absorb impurities

PVDF (polyvinyldilene fluoride)

- Broader range of chemical resistance than polypropylene

- Suitable for high process temperatures

- Ideal for HF and BOE processes at high temperatures

PTFE (Teflon®)

- Resistant to an extremely wide range of chemicals

- Perfect for KOH and HF acid (which etch quartz)

- Softer than quartz, so care must be taken to avoid scuffing, staining

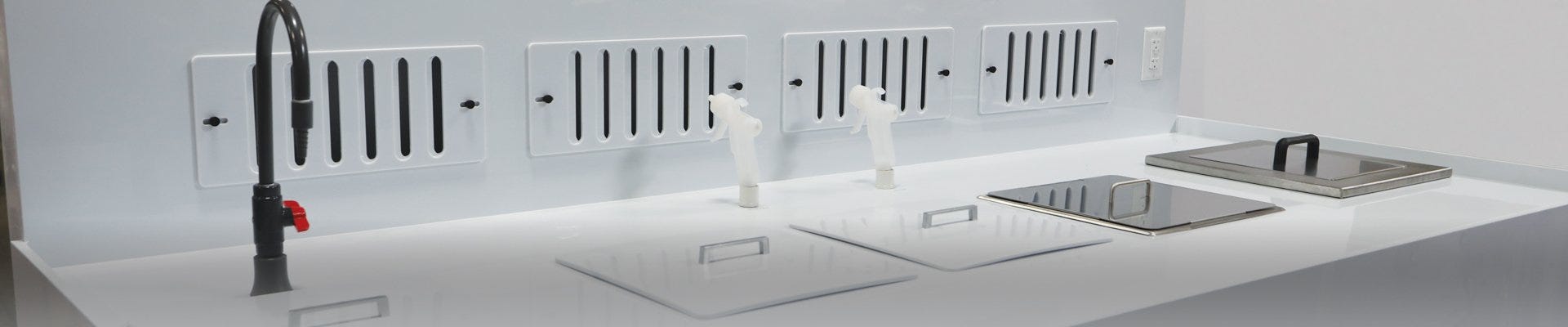

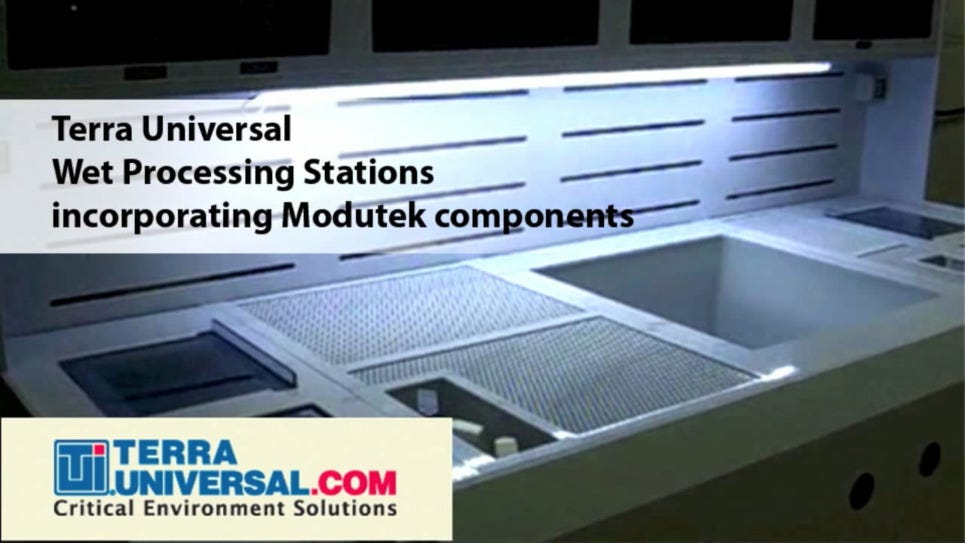

Terra’s comprehensive range of constant-temperature baths, etching baths, dump risers, and other processing equipment is ideally suited for the high-purity requirements of the semiconductor industry. Microprocessor controls ensure the integrity of your operations.

The chart below indicates the baths best suited for common semiconductor operations. Once you select the equipment that meets your requirements, a Terra process engineer will help configure a turnkey solution.

Product Application Chart

| Commercial or Generic Name | Process | Chemical Composition | Concentration | Typical Temperature | Recommended Product |

|---|---|---|---|---|---|

| Aqua Regia | Gold Etchant | Hydrochloric Acid (HCl) Nitric Acid (HNO3) | 75% 25% | 90° | C Series |

| Buffered Oxide Etch (BOE) | Etch SiO2 | Ammonium Fluoride (NH4F) Aqueous Hydrofluoric Acid (HF) Aqueous | 40% | 15-40°C Ambient | A Series RCe Series |

| CP8 | Etch | Nitric Acid (HNO3) Hydrofluoric Acid (HF) | Ambient | A Series | |

| Etch (Indium) Molybdenum Platinum Nichrome | Etch | Hydrochloric Acid (HCl) Aqueous Nitric Acid (HNO3) | 37-38% 70-71% | QA Series | |

| Metal Etch | Etch A, AlSi Al Si Cu | Phosphoric Acid (H3PO4) Acetic Acid (CH3COOH) Nitric Acid (HNO3) | 85-87% | 30-60°C | QA Series |

| Nitride Etch | Etch | Phosphoric Acid (H3PO4) DI Water (H20) | 85-87% 15-13% | 150-185°C | Nb Series |

| Organic Stripper | Resist Removal | PRS-1000 S-43 Lozolin No Phenol-922 | Full strength | Room Temperature 120°C | Nb Series |

| Oxide Resist Strip | SiO2 Resist Stripping | Sulfuric Acid (H2SO4) Ammonium Persulfate (NH4S2O2) | 95-96% | QA Series | |

| Phenolic Stripper | Resist Removal | J100 Bermar 712D R-10 | 95-100°C | C Series | |

| Resist Series (Metalized) | Resist Removal | Chromic Sulfuric Acid (CrO3+H2SO4) | A Series | ||

| R.C.A. Clean | Pre-Diffusion Cleans Quartzware | Step 1: Water Hydrogen Peroxide (H2O2) Ammonium Fuoride (NH4CH) Step 2: DI Water (H2O) Hydrogen Peroxide (H2O2) Hydrochloric Acid (HCL) | 40% | 75-85°C | Qa Series |

| Silicon Etch | Etch | Acetic Acid (CH3COOH) Nitric Acid (HNO3) HydroFuoric Acid (HF) | Ambient | A Series | |

| Sirtl Etch | Etch | Chromium Trioxide (CrO3) DI Water (H20) Hydrofluoric Acid (HF) | Ambient | A Series | |

| Slope Etch | Etch | Phosphoric Acid (H3PO4) Acetic Acid (CH3COOH) Nitric Acid (HNO3) | 55°C | Qa Series | |

| Standard Resist Strip (do not use w/aluminum) | SiO2 Resist Strip | Sulfuric Acid (H2SO4) Hydrogen Peroxide (H2O2) | 95-96% | 110-140°C | Qa Series |

| 2:1 Etch | Etch | DI Water (H2O) Hydrofuoric Acid (HF) | Ambient | A Series | |

| Wafer Rinsing | Rinsing | DI Water (H2O) | 100% | Ambient | DR-Series |

Can't find what you're looking for?Tell us what you need and we'll build it!