Learn More: BioSafe Features

More Information

All-Steel BioSafe Panels

Engineered for ease of installation and cleaning, BioSafe Cleanroom wall panels come in standard 4-foot widths and heights ranging from 7 to 12 feet. Their modular design lets you configure a custom cleanroom using pre-engineered components, many of which are inventoried at Terra’s Fullerton, California manufacturing facility.

Terra technicians assemble and test each BioSafe Cleanroom to ensure it meets performance requirements prior to packaging. Panels and other components are labeled before crating to simplify installation, which typically requires no special contracting or permitting (on-site installation and testing services are available). Whether your requirements call for a single room or a multi-suite facility, your BioSafe Cleanroom is operational in a fraction of the time and at a fraction of the cost associated with conventional cleanrooms.

Each wall section is composed of two panels that snap together, with space in between for insulation or utilities, similar to a conventional wall. Wall sections are bolted end-to-end to form a continuous interior wall surface with very fine seams that can be caulked if necessary. Wall panels can be fitted with flush-mounted BioSafe windows or any of Terra’s cleanroom door designs. Certain panels will include the required exhaust vents; customers can specify the addition of an exterior exhaust plenum that covers these vents and directs exhaust airflow to an external air handling system. Air return plenums may also be used to recirculate conditioned air to maintain suitable working temperatures and save energy.

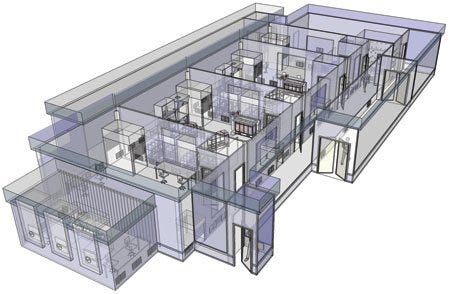

Multi-Room Configurations

BioSafe wall panels function equally well as exterior and interior cleanroom walls, which simplifies engineering of multi-room facilities. Corridors and anterooms can be added where necessary by regulation or to provide additional barriers against cross-contamination. These intermediate spaces help to maintain proper air pressure by providing neutral buffer spaces. They also may serve as convenient staging areas for supplies and other materials. Pass-through chambers can also be used for more staging and transfer, as well as simply limiting the number of personnel in a critical area.

The modular ceiling grid can be configured for different ISO-classifications through appropriate placement of fan/filter units. FFUs can be positioned (and repositioned) in the ceiling grid to concentrate clean air in the most critical processing areas. Rooms with less critical cleanliness requirements may operate with fewer FFUs, reducing energy and maintenance expenses. For example, a gowning room may only need one FFU to ensure a slight overpressure that limits leakage.

As FFU configurations become more complex, Terra can provide more advanced control systems, from PLC touchscreen controllers to fully automated air balancing systems. In addition, security measures can be integrated into the various access points of the cleanroom, including biometric scanning equipment and access logs.