- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

-

Fully-integrated, end-to-end hybrid and stick-built cleanrooms including wall panels, frames, ceilings, air handling, and filtrationClose

-

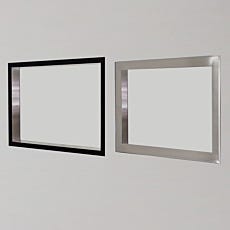

Frameless or framed flush-mount windows; single or double-sided designs compatible with any wall material or thicknessWindow Features Overview

28 Products

Close28 Products

-

Portable, accurate, precise and easy to use, air particle counters ensure clean room, glove box, hood or other enclosure meet ISO cleanliness requirements.

39 Products

Close39 Products

-

Reusable cleanroom garments are noncontaminating, even after repeated laundering, and resist snagging; select lint-free polyester, super dense polyester and static-control carbon grid

120 Products

Close120 Products

-

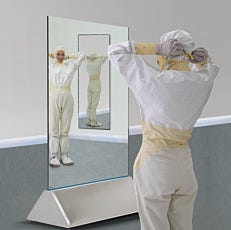

Cleanroom-grade, copper-free mirrors combine safety, cleanliness, and corrosion resistance in space-saving designs that allow a self-check of proper gowning prior to entering cleanroom.

39 Products

Close39 Products

-

Suitable for ISO Class 4-8 cleanrooms, HEPA/ULPA filtration vacuum cleaners contain sub-micron particles; specialized units for explosive material, mercury or cyanide recovery.

81 Products

Close81 Products

-

General Purpose -20°C Lab Freezers from Thermo Fisher and Helmer Scientific

47 Products

Close47 Products

-

Terra offers high-precision instruments for monitoring pressure, velocity and flow of air in cleanrooms, gloveboxes, hoods, and other enclosures

59 Products

Close59 Products

-

Vortexers by Thermo Fisher and Benchmark Scientific for sample, reagent and media mixingVortexer Features Overview

27 Products

Close27 Products

-

Disposable cleanroom garments shield personnel and product from contaminants; non-woven materials limit lint generation, and economical pricing allows garment disposal.

64 Products

Close64 Products

-

Organize cleanroom gloves, booties and garments as well as safety glasses, wipers and other lab supplies; bench and wall models conserve space, and BioSafe models simplify cleaning.

199 Products

Close199 Products

-

UV-C sanitizers use precise wavelengths of light to disinfect rooms, enclosures, parts, tools and surfaces; effectively inactivates most bacteria, viruses and molds spores

32 Products

Close32 Products

-

Terra offers high temperature/acid gloves, disposable and reusable cleanroom gloves, static-safe gloves, glove liners and finger cots

49 Products

Close49 Products

-

Easily accomplish out-of-reach cleanroom tasks; meet OSHA safety and load capacity standards; BioSafe stainless steel design with continuous seam welds is ISO 5-compliant.

138 Products

Close138 Products

-

Compounding cleanrooms feature ISO-rated anterooms to comply with USP 797 and 800 requirements for sterile drug preparationsPharmacy Compounding Cleanroom Features Overview

22 Products

Close22 Products

-

Custom and preconfigured modular cleanrooms meet ISO 5-8 and sterile processing requirementsFan Filter Units Features Overview

271 Products

Close271 Products

-

Safely contain chemical, biohazardous, and general waste; durable stainless steel or plastic construction resists chemicals, contains leaks, prevents spills and ensures long service life.

72 Products

Close72 Products

-

Transform any space - warehouse, lab, office, production area - into an ISO-rated cleanroom with Terra's turnkey conversion packageCleanroom Conversion Features Overview

275 Products

Close275 Products

-

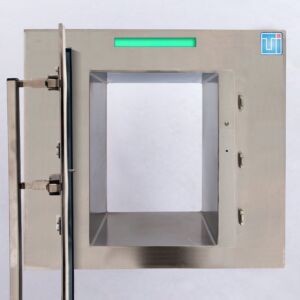

HEPA filtered pass-throughs protect against particle contamination, exceed USP 797 and 800 pharmacy compounding standards HEPA Filtered Cleanroom Pass-Through Explained

17 Products

Close17 Products

-

Transfer documents and small parts into a lab or medical clinic. Controls access and minimizes foot traffic in sensitive areas.

46 Products

Close46 Products

-

Compounding Aseptic Containment Isolators (CACIs) or Class II, Type A1 or A2 nuclear pharmacy isolators meet USP 797 and ISO Class 5 for sterile compounding of radiopharmaceuticals

11 Products

Close11 Products

-

Designed for transferring tall carts or large equipment into a cleanroom on a regular basisRoll-Up Door Passthrough Explained

3 Products

Close3 Products

-

Replacement parts and accessories, including filters, for laminar flow hoods, fume hoods, and biosafety cabinets

677 Products

Close677 Products

Product Comparison

Select and compare up to 4 product families

Features and Benefits

Critical Environment Solutions

Terra's mission is to help customers in highly regulated industries transform the world with critical environment solutions that improve health, safety, performance, and yields. These environments may comply with stringent UL, ISO, IEST, ASTM and OSHA standards and local requirements.

Hoods and BioSafety Cabinets Meet ISO 5 Compounding Requirements

WhisperFlow laminar flow hood meets ISO 5 Primary Engineering Control requirement of USP-797; Purifier Logic Biosafety Cabinet is ideal for hazardous drug containment, per USP-800 regulations

Framed Double-Flush Cleanroom Window for Pharmaceutical Compounding Rooms

Dual-pane window sits flush with wall surface, design is free of cracks and crevices where contaminants can aggregate. Design meets USP and medical-grade requirements.

-fb.jpg)