Laminar Flow Hood Frequently Asked Questions

What is a laminar flow hood and how is it used?

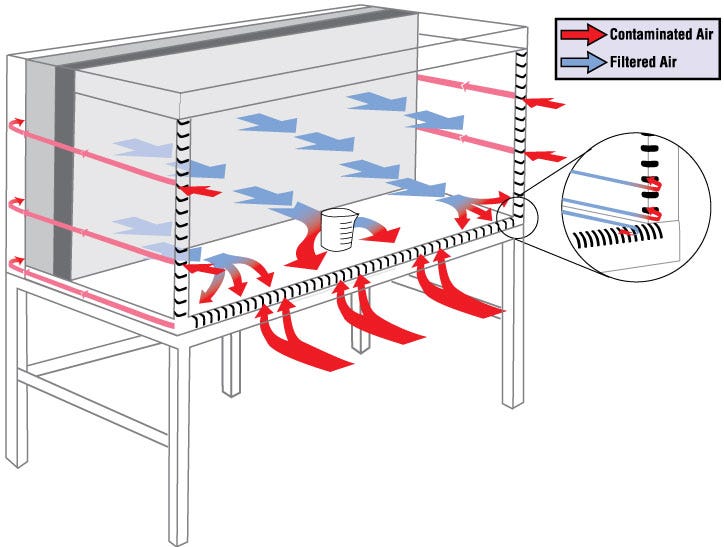

A laminar flow hood, or laminar flow clean bench, controls particle-driven contamination by washing the work area with uniform, unidirectional, HEPA-filtered air. By design, a laminar flow hood will mitigate turbulent eddies, such as second-pass air, that deposit particles randomly on surfaces throughout the working zone, causing cross-contamination. To maintain an environment that protects samples, reactions and equipment from contamination, laminar flow hoods sweep micro-filtered air from the cleanest work zone – directly underneath the filter face – to the exit area, located at the front sash. This air flow design applies to both horizontal and vertical laminar flow configurations, motivating users to perform their work closer to the filter face (and away from turbulence-inducing obstructions, such as sample racks or analytical instrumentation). Vertical and horizontal flow hoods each offer distinct advantages; understanding the benefits of each configuration will enable flow hood operators to enclose their processes with a design that supports their objectives.

What is the difference between a Horizontal and Vertical Laminar Flow Hood?

There are compelling reasons to choose either airflow system depending on clearance requirements, process location, work surface design, and operator safety. Below is a brief comparison (read more on horizontal vs vertical laminar flow hoods)

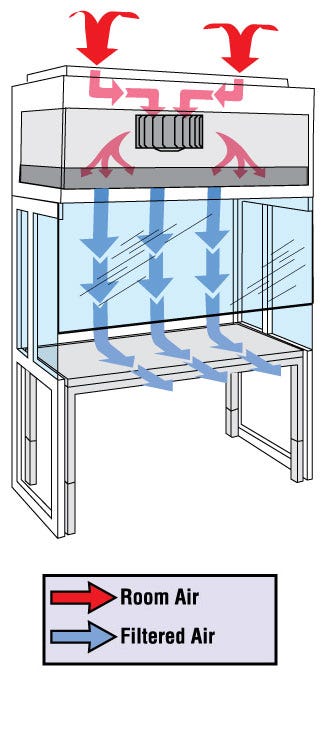

Vertical Laminar Flow Hood

The fan filter unit (FFU) and HEPA filter, installed above the work zone, draws ambient room air from above the vertical laminar flow hood, or clean bench, downward across the work area toward the front exit sash. In essence, the air flow pattern of a vertical laminar flow bench mirrors that of a laminar flow cleanroom with ceiling-installed HEPA filters.

Advantages:

- Smaller footprint design fits on top of a standard lab bench

- Front sash protects the operator from exposure to nuisance odors or reaction emissions

- Unobstructed access to the HEPA filter for certification testing or filter changes

- Comprehensive washing of work surface with clean air reduces rate of sample cross-contamination during reaction prep

- Process equipment or analytical instrumentation unlikely to block work zone from HEPA-filtered air.

- Purchase of perforated workstation further enhances laminarity

- Isolated work surface and anti vibration table available for microscopy work

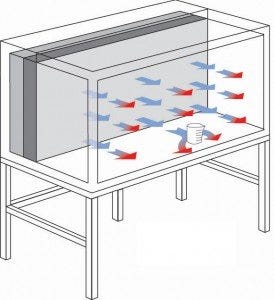

Horizontal Laminar Flow Hood

The HEPA filter, installed in the rear of the work zone, draws ambient room air from behind the horizontal flow hood laterally across the work area toward the front exit sash. A horizontal flow hood require additional depth to accommodate the rear-mounted blower and make-up air space needed to feed the system.

Advantages:

- Shield-free design supports unobstructed work area access

- Operator sits downstream of process, less likely to contaminate samples or reactions

- Reduced turbulence from air striking work surface

- Shorter vertical clearance fits in spaces with low ceilings

- Equipment installed above work area, like IV bars or overhead stirrers, will not impact work surface cleanliness

What are some common laminar flow hood applications?

Vertical and horizontal laminar flow benches are widely used across many different industries, from contact lens testing and smart phone screen development to circuit board assembly and nutraceutical research. The most prevalent laminar flow hood applications have informed the development of specific designs crafted to support the unique needs of each operation.

Microscopy Flow Hood

Vertical laminar flow hoods, with vibration isolated work surfaces and bellows-compatible shields, are designed to support microscopy operations, from cell counting to microelectronic assembly. The vibration-free work station, or surface-mounted anti vibration platform, reduces operator fatigue and nausea stemming from intrinsic building vibrations. Certain models feature bellows eyepieces integrated with the front hood shield to protect the operator from exposure to nuisance vapors or odors. For secondary disinfection purposes, models are equipped with UV germicidal lamps designed to denature microbial genetic material. For assembly of static-sensitive electronics, microscopy flow hoods feature side and back panels composed of static-dissipative PVC to prevent electrostatic build-up.

PCR Hood

Benchtop vertical laminar flow hoods, equipped with UV disinfection lamps, support polymerase chain reaction prep and assay development. A PCR hood maintains ISO 5 conditions within the work area by ensuring HEPA filter coverage above the entire work surface. UV-C lamps emit germicidal light at 254 nm to prevent microbial contamination of samples and false amplification positives. PCR hoods are installed on vibration-free tables to prevent ambient vibrations from affecting the performance of thermal cyclers, benchtop centrifuges and analytical balances. PCR hoods are designed to small footprints to fit within crowded, shared lab spaces.

Wet Processing Flow Hood

Free-standing, large footprint laminar flow hoods, equipped with integrated PLC controls, enclose wet stations to support sterile wafer processing and cleaning. Composed of acid-resistant 304-grade stainless steel or opaque polypropylene, a wet processing hood resists corrosion and degradation stemming from acid spills or vapor exposure. Open-body design leaves space for carboys, baths, sinks, spray stations, circulators and storage cabinets. The PLC controller includes a filter replacement alarm and energy-efficient night mode setting.

Cell Culture and Mycology Flow Hood

Benchtop laminar flow hoods are designed to maintain sterile environments for mammalian tissue culture or microbial cell culture studies. Cell culture hoods maintain an ISO-5 environment to prevent colony cross contamination. Powder-coated or 304-grade stainless steel hood frames are mounted on stainless steel work surfaces to preserve aseptic conditions. Fluorescent or LED lights illuminate the work area to support colony picking. Larger-footprint laminar flow cabinet designs can include space for CO2 incubators, plate handlers, petri dish stackers and colony pickers. UV-C germicidal lamps provide secondary disinfection of the work surface by denaturing microbial nucleic acid strands.

Contamination control is also key for work related to mycology (study of fungi). A laminar flow hood for mushroom cultivation eliminates contamination exposure problems of a cumbersome Still Air Box (SAB). The micro-filtered clean environment inside a laminar flow hood is optimal for making and working with agar plates, spore syringes, spore prints, and much more.

Sterile Drug Compounding Cleanroom Hood

Vertical and horizontal laminar flow cabinet designs meet USP <797> requirements to enclose compounding of non-hazardous sterile preparations, such as TPNs and antibiotics. A pharmacy compounding hood includes an internally-mounted IV bar to hang saline bags and lateral space for sharps containers, syringes, totes and active pharmaceutical ingredients. Certain models include motorized front shields to support hands-free entry into the critical compounding area. LED lights illuminate the work area and UV-C germicidal lights provide secondary work surface disinfection. Transparent plastic side panels and front shield support remote quality control procedures.

Explosion-Proof Laminar Flow Hood

An explosion-proof laminar flow hood is designed to work in hazardous areas with risk of ignition due to flammable fumes or explosive dusts. All electrical components in explosion-proof hood designs are rated compliant for hazardous locations Class I, Division 1, Groups C & D and Class II, Division 1, Groups F & G. This includes the fan filter unit (FFU), LED lights, wiring, and on/off switches.

Can't find what you're looking for?Tell us what you need and we'll build it!