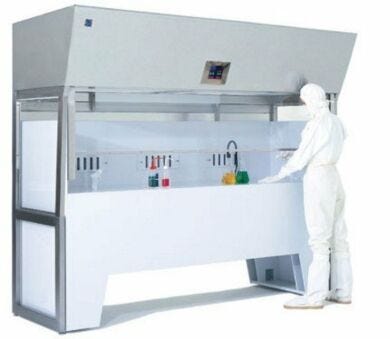

- Available ISO Ratings: ISO 6, ISO 7, ISO 8

- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Here at Terra Universal, we’ve made it our mission to offer the best possible lead times in the industry. In addition to aggressive stocking programs and streamlined fulfillment, Terra Universal also offers several services that ensure you receive your products as quickly as possible.

FasTrak 24/7 guarantees to meet the shipping date YOU specify, regardless of quoted lead times.

Terra Universal can provide FasTrak 24/7 service for both in-stock products and custom orders.

Examples of FasTrak 24/7 services include:

Terra FasTrak service fees are only meant to cover the cost of additional Terra services, they are not designed to generate profit. If Terra fails to ship on or before the specified date, Terra will refund up to 100% of the FasTrak charges at the client's request. This guarantee does NOT cover direct, special, consequential, or other damages. It is strictly limited to 100% of the amount paid for the FasTrak service.

The FasTrak 24/7 refund policy does not apply when a specified ship date is missed due to factors outside Terra's control, such as vendor performance or shipping company delays. The FasTrak 24/7 guarantee DOES apply in instances where the shipping date is missed due to Terra's own negligence.

Mon - Fri, 09:00 AM - 08:00 PM PST

Tel: +1 (714) 578-6100

Email: [email protected]

On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.