- Available ISO Ratings: ISO 6, ISO 7, ISO 8

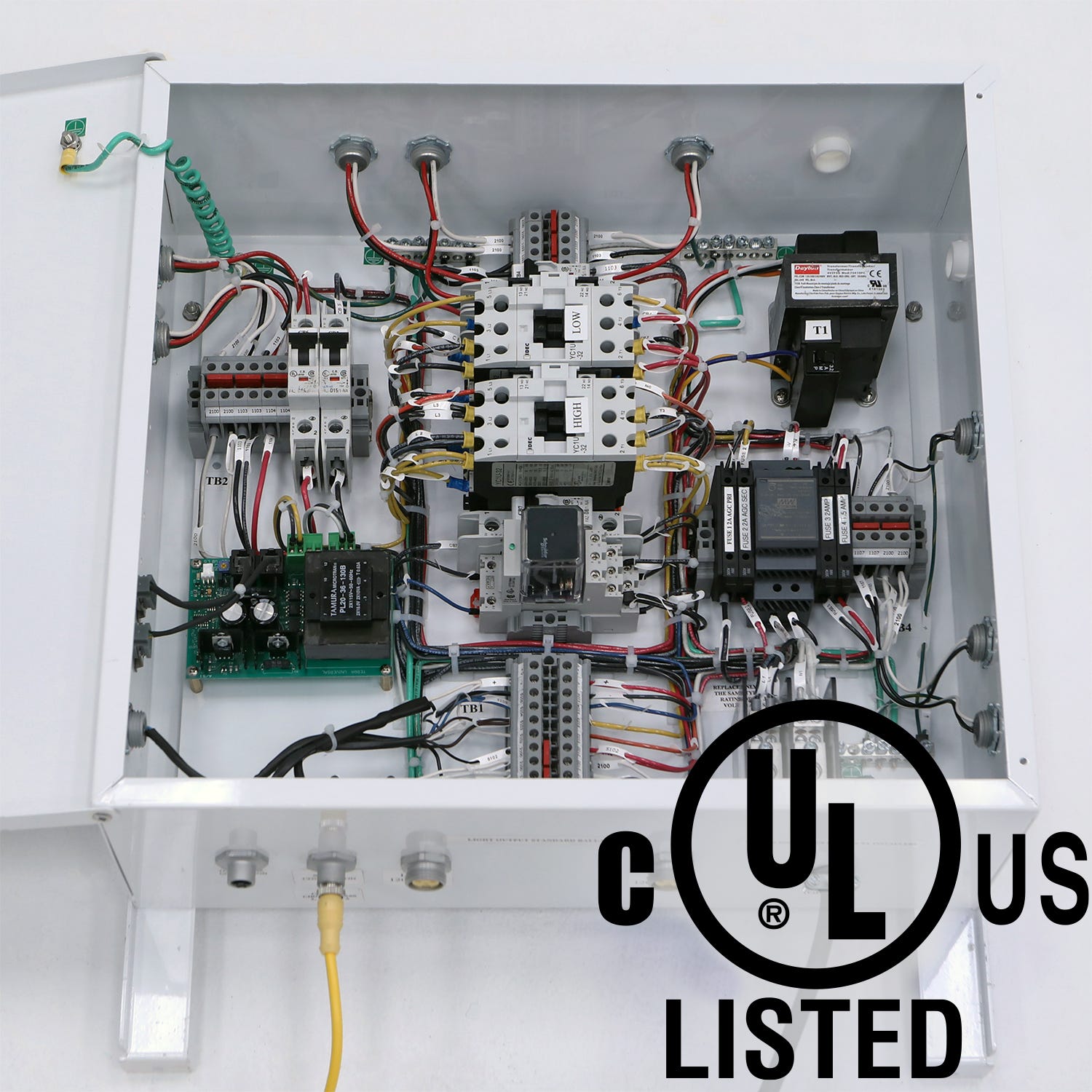

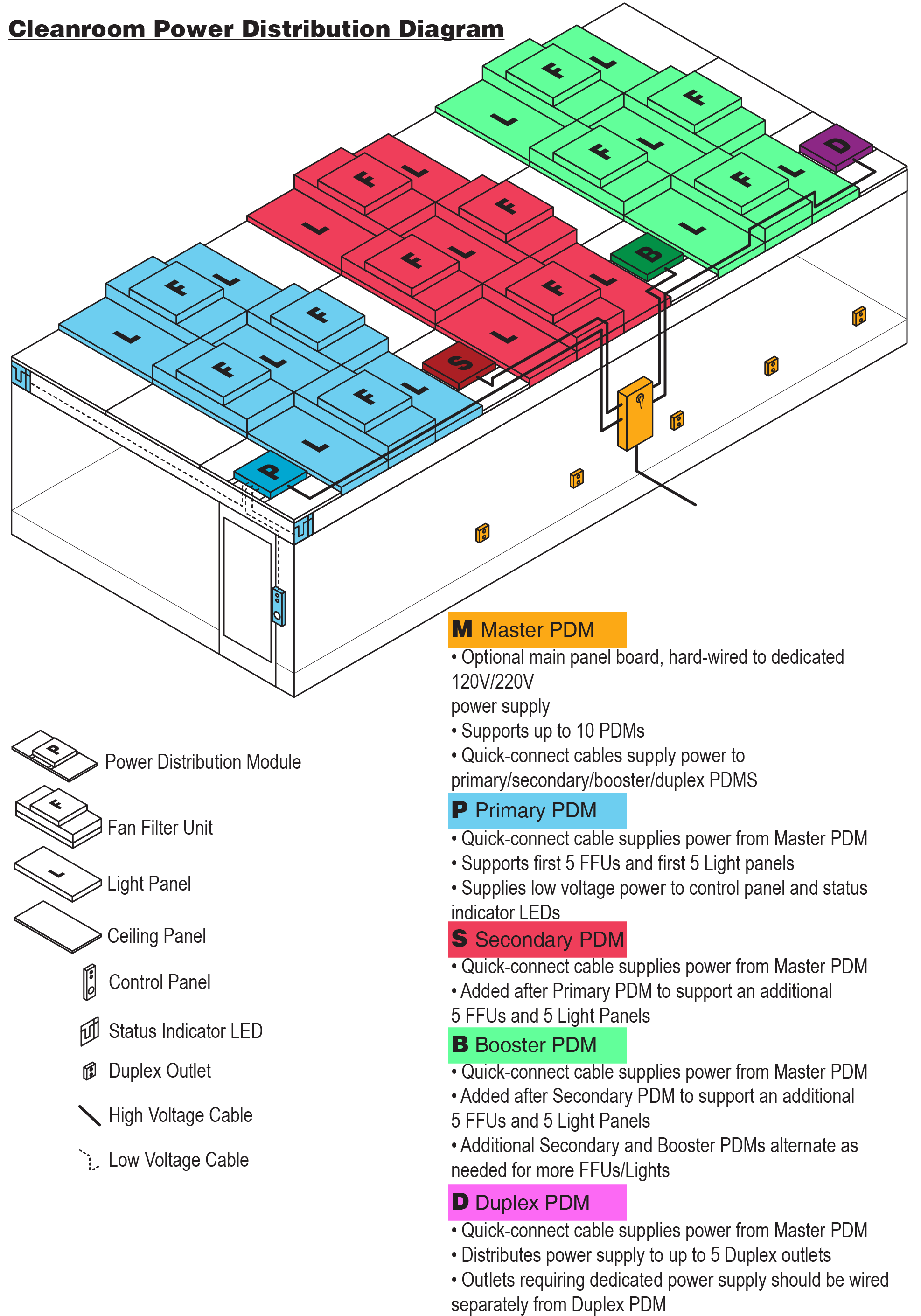

- Cleanroom control panel provides convenient, centralized access to monitor and adjust cleanroom controls

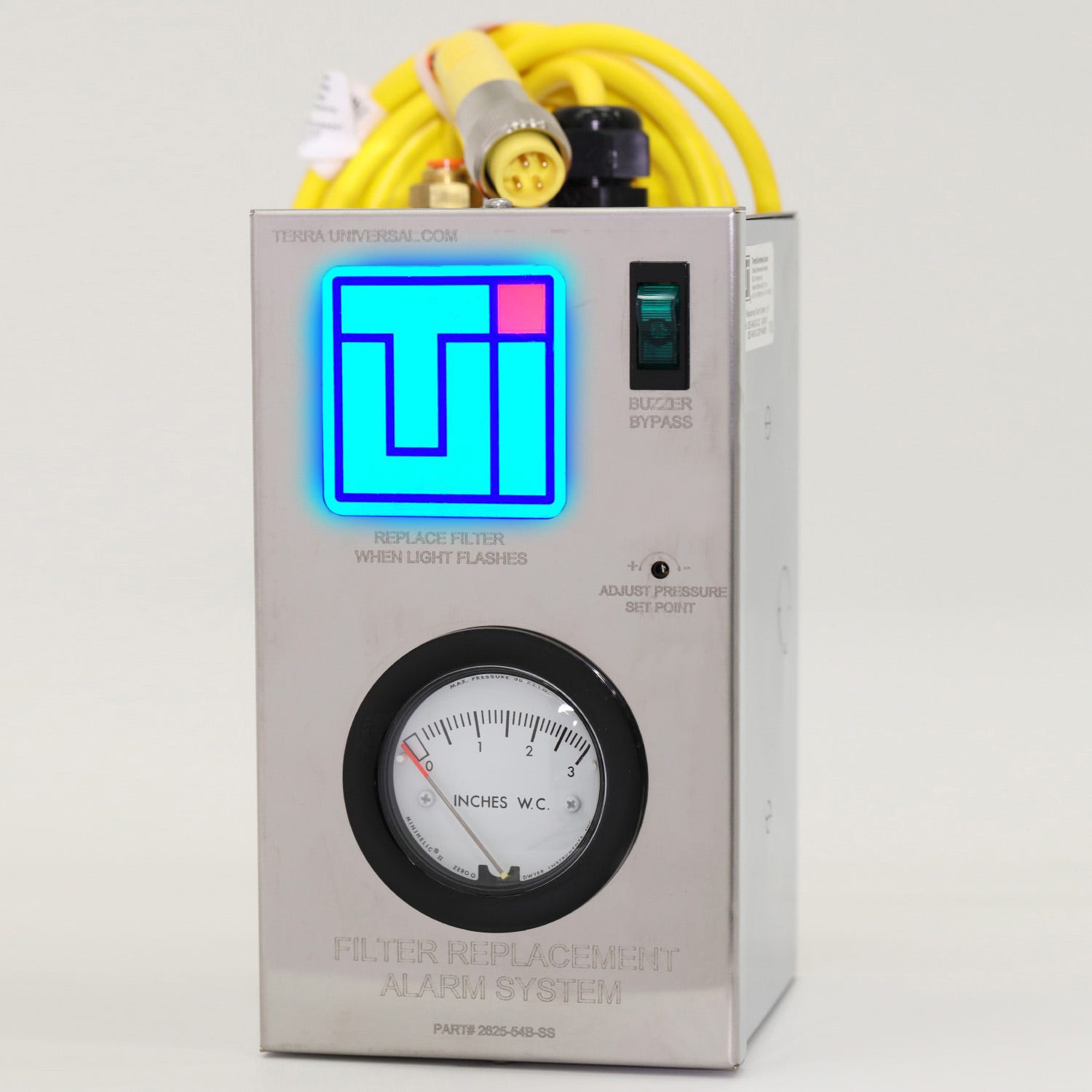

- Includes differential pressure gauge, power switches for FFUs and lights, and a filter replacement alarm

- Integrated filter replacement alarm keeps your fan filter units working safely and efficiently

- Night Service switch automatically sets FFUs to low power mode to shave 25% of energy costs

- Upgrade to Smart® control panel for more environmental sensors and advanced control of up to 200 FFUs

• Cleanroom Type: BioSafe®

• Mounting Position: External

• Night Switch: Yes

• Unit of Measure: EA