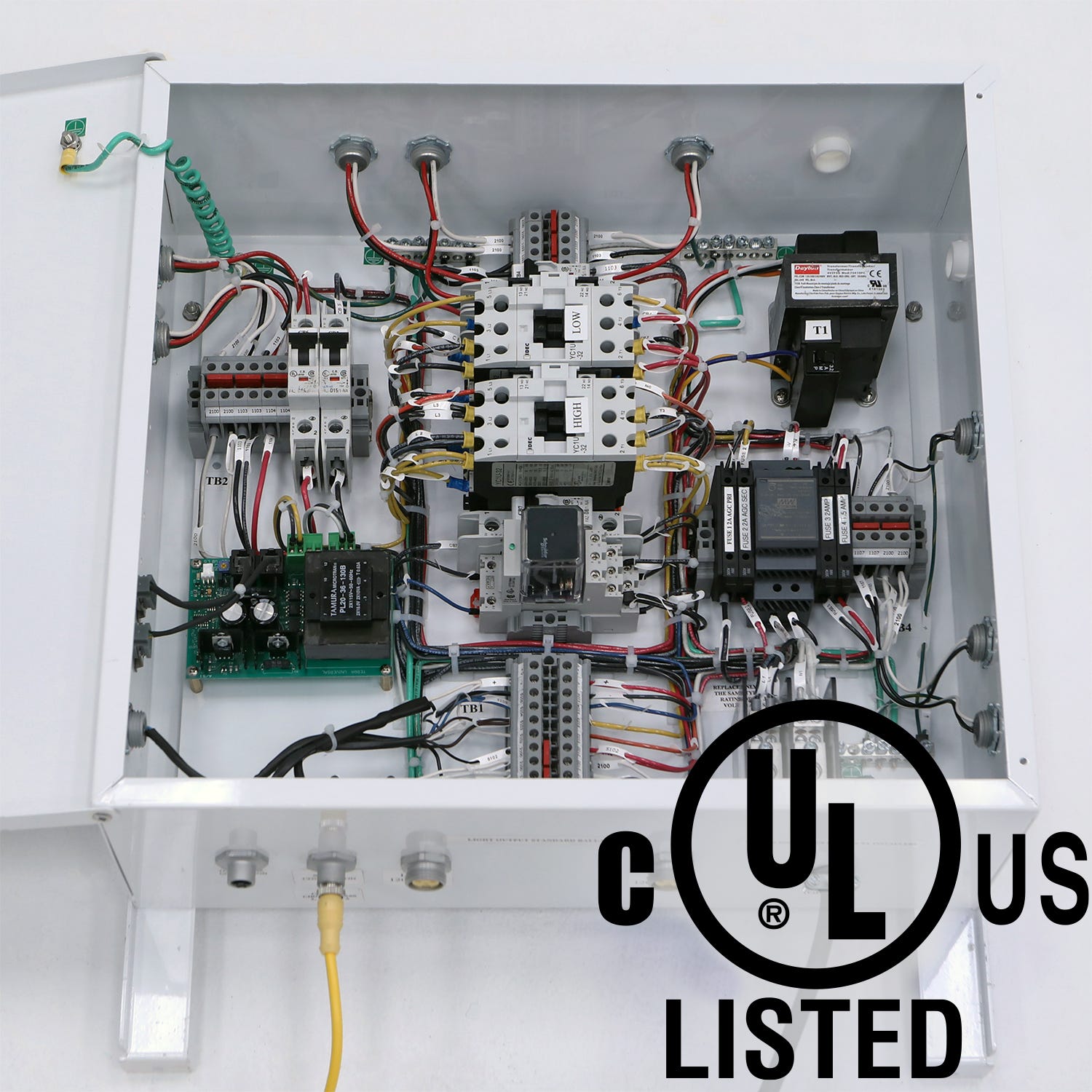

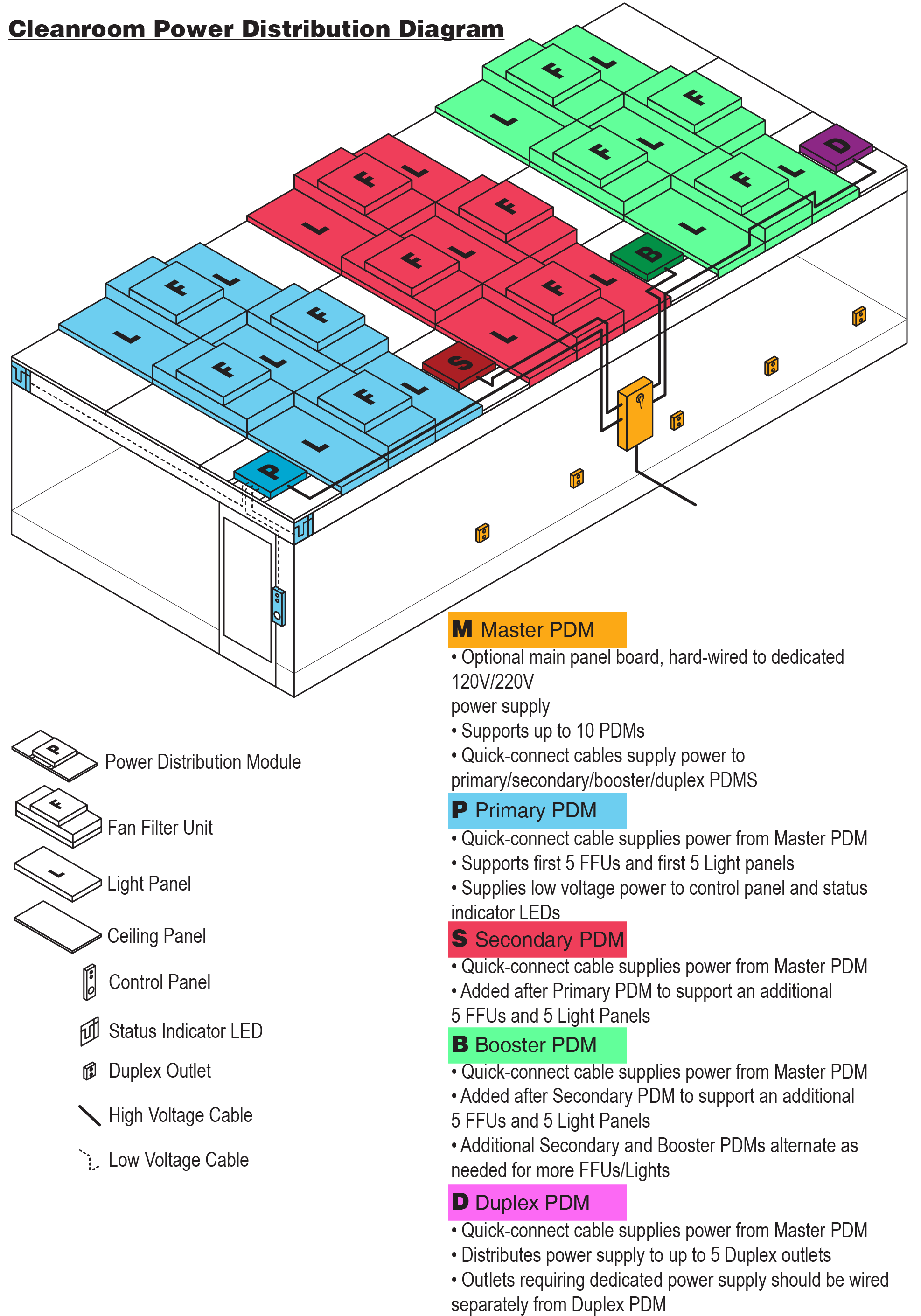

Power Distribution Module Diagram

- PDMs house electrical components in an easy-access housing that makes it easy to add fan/filter units or lights if requirements change

- Control Panel with Operation Status Indicators provides convenient access to all controls and a visual confirmation of cleanroom operation

- Plug-and-play, modular design speeds up installation, whether of Terra-furnished modular cleanroom or Terra cleanroom components used in your own cleanroom structure

Terra’s Power Distribution Modules (PDMs) dramatically simplify connection of fan/filter modules (FFUs) and ceiling lights, while providing low-voltage power for one or more Control Panels

Each PDM accommodates up to 5 lights and 5 FFUs and must be wired to a dedicated 35A fused 120V circuit or a 30A fused 240V circuit. Select among four PDM types (see configuration chart below):

UL-Listed for Highest Safety and Quality

Ensuring the safety of your employees, customers, and products is essential. Terra's UL-listed PDM's and air filtering systems are manufactured to the highest standards to reduce the risk of damage, injuries, and electrical hazards such as electric shock and fires. UL (Underwriters Laboratories) is recognized around the world as the leader in product safety testing and certification. The UL listing helps meet municipal and other permitting requirements that may be required before a cleanroom can be approved for operation. It ensures safety and integrity of high voltage cleanroom electrical system, as evaluated by independent third-party UL.

Leave Room for Growth!

If there’s chance that you may require additional FFUs to accommodate cleaner conditions, leave each PDM below its maximum FFU capacity. FFUs and lights can be added at any time, with no need for an electrician or hard-wiring, as long as the maximum of five of either module per PDM is not exceeded.

Control Panel

- Provides centralized control and monitoring of cleanroom functions

- Typically mounted at the main entry of the cleanroom

- Optional Night Service Mode switches FFUs into low-energy mode during off-hours to lower operating costs without shutting down the cleanroom.

- Can be upgraded to Smart Control System for added environmental sensors and FFU control to meet critical performance/monitoring requirements.

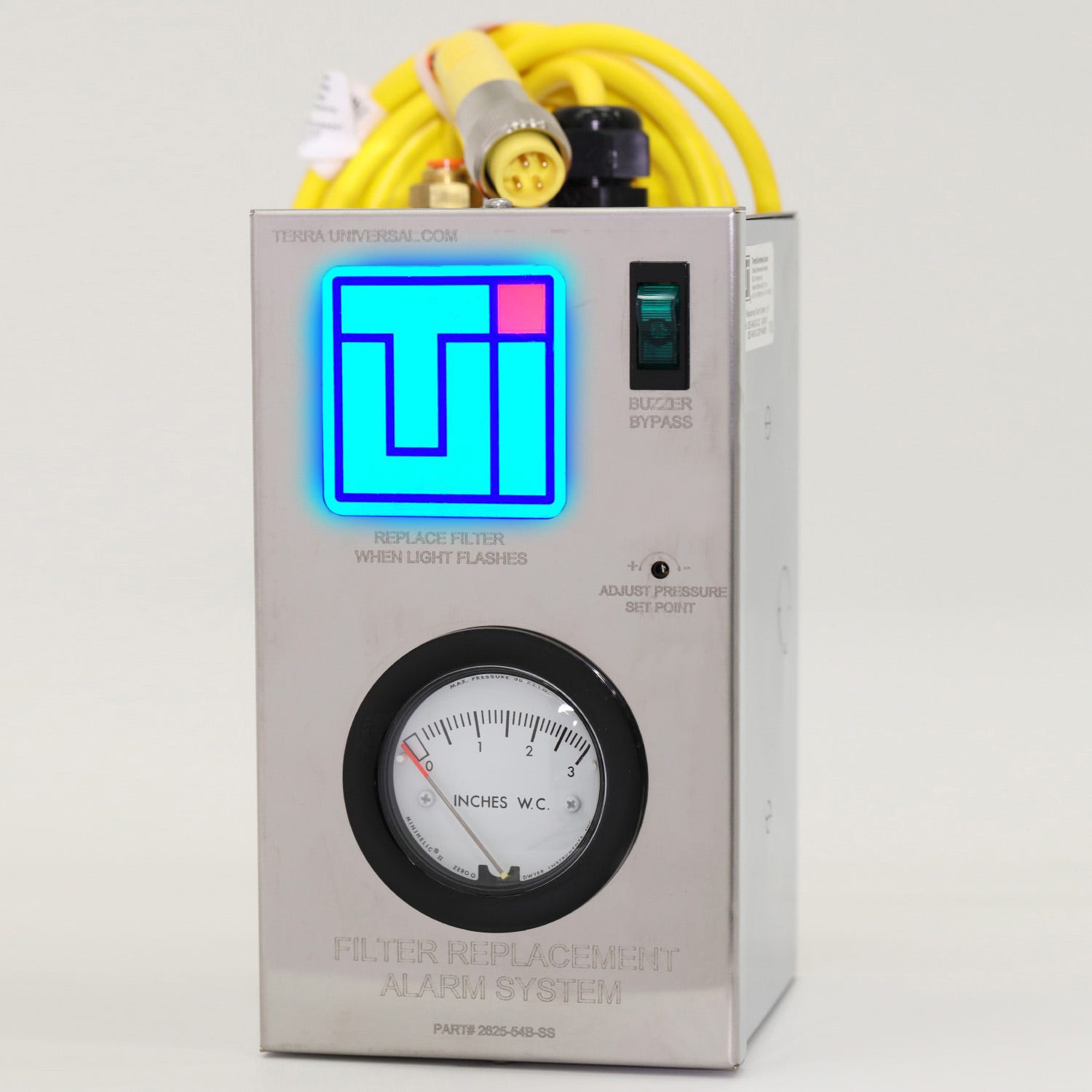

Filter replacement alarm

- Helps avoid unexpected and costly cleanroom operational interruptions by automatically alerting for cleanroom filter replacements

- 1 Filter Replacement Alarm can cover for all Filter Fan Units (FFUs) in the cleanroom

- Provides both audible and visual alarm

- Audible: Buzzer with silencer

- Visual: TUI Logo flashes

- Includes adjustable alarm set-point to adjust frequency of filter replacement based on backpressure within a FFU

- Typically mounts next to the cleanroom control panel

- Connections:

- Power: power connects to either the cleanroom’s power distribution module, or to a standard 120V/220V outlet

- Pressure: ¼” plastic tubing connects from the alarm unit to one FFU

Night Service Switch

- Energy-saving mode saves 25% of fan operating costs by reducing power consumption during off-hours

- Maintains round-the-clock cleanroom integrity at lower cost

- Easy to activate via panel-mounted switch (Wireless Cleanroom Control System also available)

Why Pay More for Less?

Terra cleanrooms are designed to meet a specified ISO cleanliness rating when a cleanroom is in use: with operations in progress, process machinery humming, and personnel in motion. So why pay to maintain that level of FFU performance when a production shift ends and people, the greatest source of contamination, leave the room?

With a greatly reduced contaminant load, a cleanroom at rest maintains its target ISO cleanliness standard with much less airflow, fewer air changes—and decreased power consumption. Terra’s Night Service Switch provides this cleanliness at a nominal cost, giving you immediate cost savings.

Simply select the “Night Service” Switch when you turn off the lights and go home. A separate operation circuit drops all Fan/Filter Units (FFUs) into low-energy operation mode, shaving 25% of energy costs off your power bill while maintaining uninterrupted cleanroom performance at your specified cleanliness level. With Terra's Night Service Switch, operators can save up to 7,000 kilowatt-hours per year with a return on investment in slightly over a year.*

Ordering Information

A complete system includes fan/filter units and Terra's standard Power Distribution Modules (order separately), in addition to the units specified below. The Night Service Switch includes electronic configuration of each FFU controlled by this system. The Control Panel includes switch settings and indicator lights for Normal Mode and Night Service Mode, as well as a tamper-resistant master FFU Off switch.

Comparative Specifications

| Operating Setting: | High Speed** | Medium Speed** | Night Service |

|---|---|---|---|

| Airflow: cfm (m^3/hr) | 808 (1373) | 717 (1218) | 654 (1111) |

| Air Speed: ft/m (m/s) | 115 (0.58) | 102 (0.51) | 93 (0.47) |

| Run Amps (Watts): | 4.3 (512) | 3.5 (416) | 3.3 (393W)* |

*25% savings over operation on high speed

**Based off of an average-sized cleanroom with 10 FFUs, active cleanroom usage of 8 hours per day, and the U.S. Energy Information Administration's given average retail price of electricity at 10.72 cents per kilowatt-hour.