- Available ISO Ratings: ISO 7, ISO 8

- Nitrogen generator eliminates the need for costly nitrogen gas cylinders

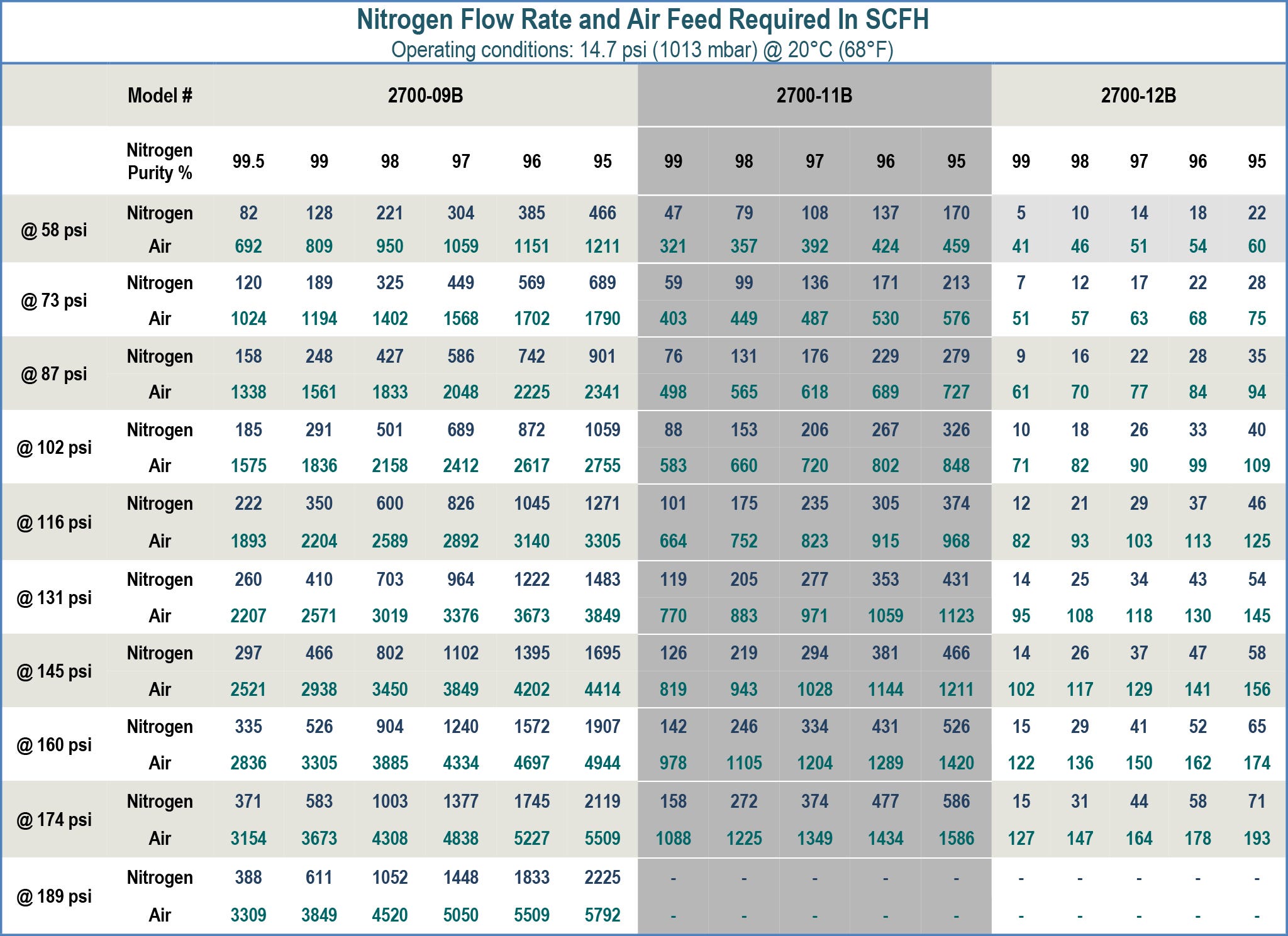

- Nitrogen membrane technology produces up to 99% pure medical grade dry nitrogen

- Ideal for continuous Nitrogen gas supply to desiccators, gloveboxes, incubators, and more

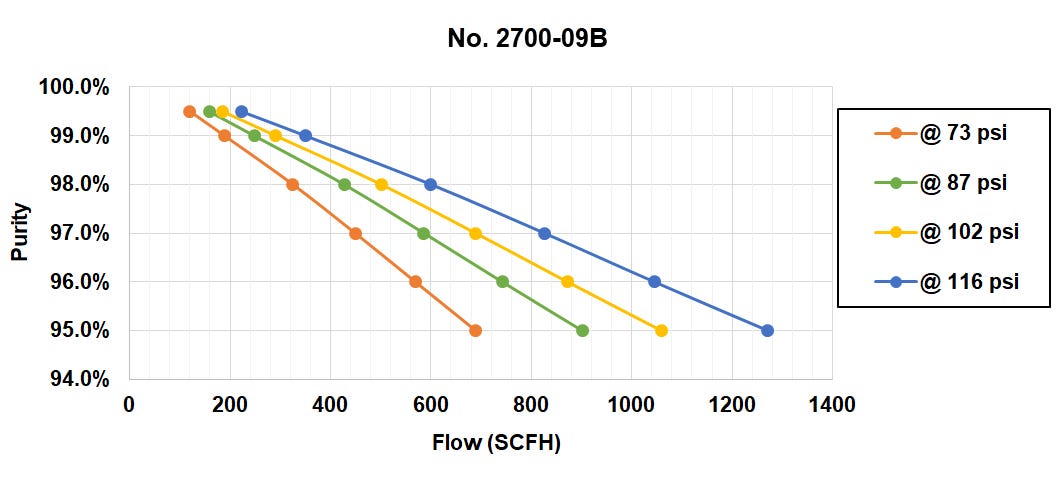

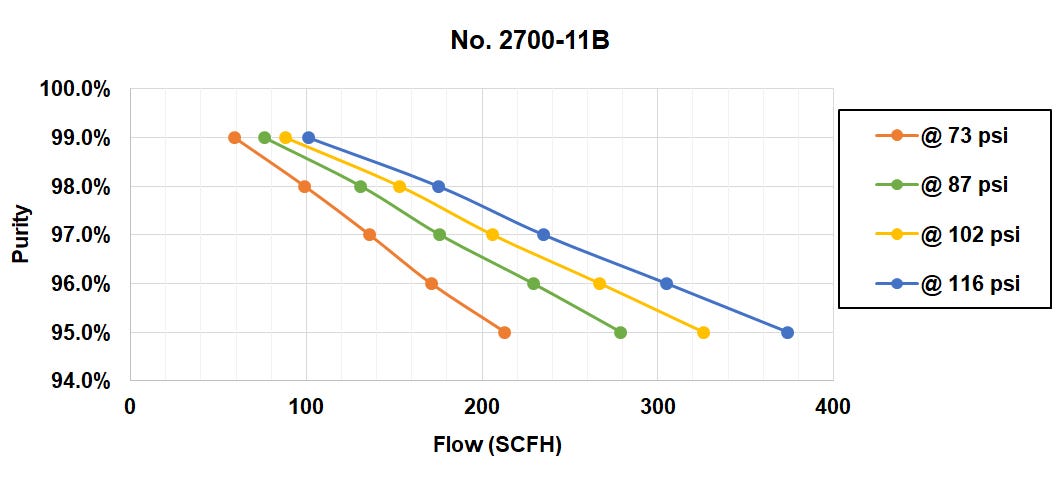

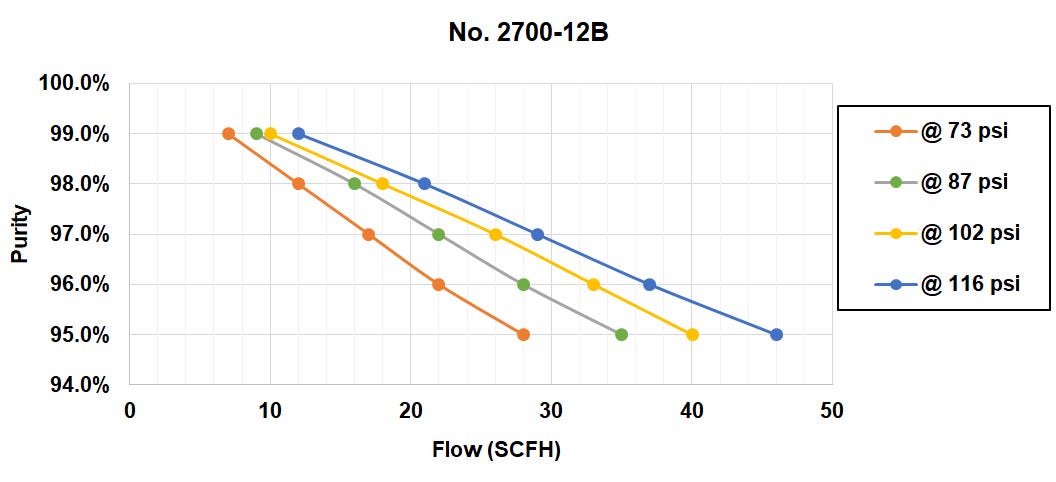

- Provides complete control over rate and purity of nitrogen gas from 95% to 99% purity

- Compact design allows set-up wherever there's a compressed air supply

• Height: 35.5"

• Depth: 12"

• Width: 20"

• Flow Rate @ 97% purity, 100 psig: 26 ft³/hr

• Flow Rate @ 98% purity, 100 psig: 18 ft³/hr

• Flow Rate @ 99% purity, 100 psig: 10 ft³/hr

• Unit of Measure: EA