Adapting Common Laboratory Hoods for Specialty Purposes

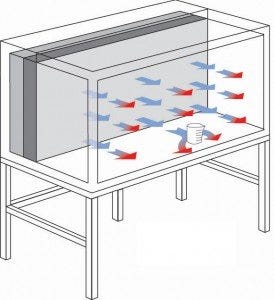

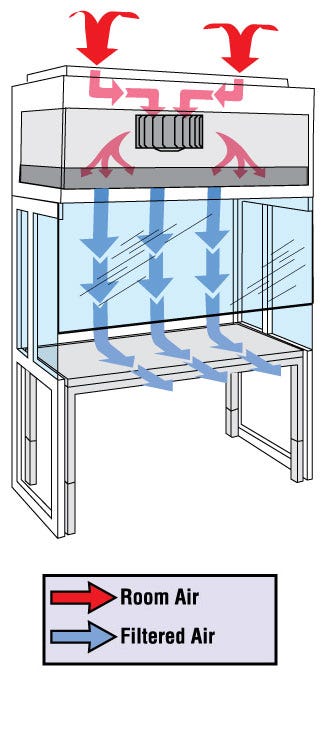

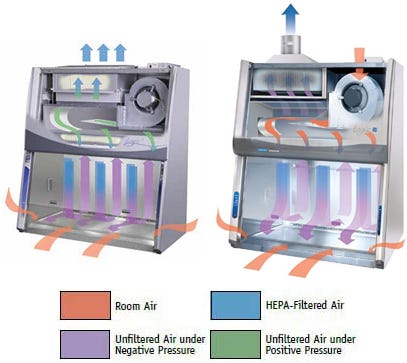

Most hoods designed for specialty applications are derived from standard laboratory configurations (e.g. laminar flow and fume hoods) adapted to specific requirements.

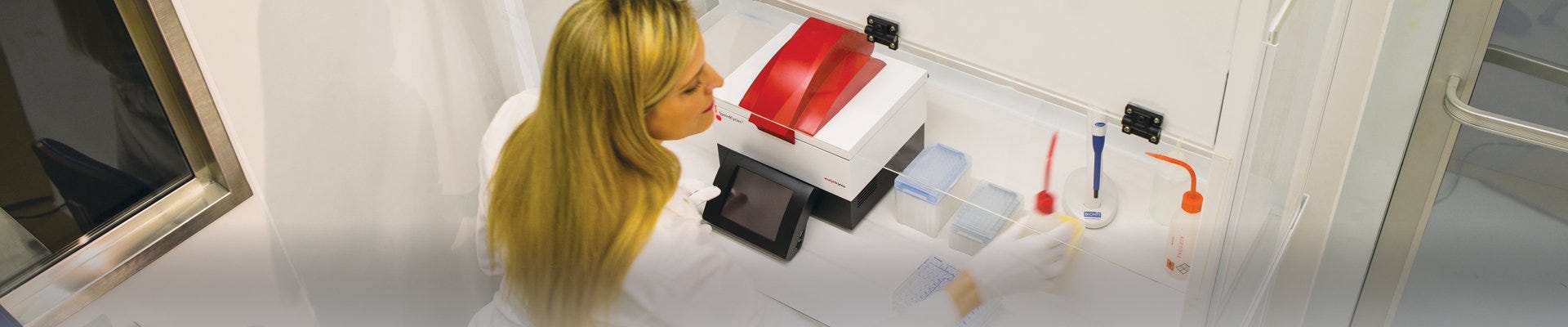

PCR Workstations

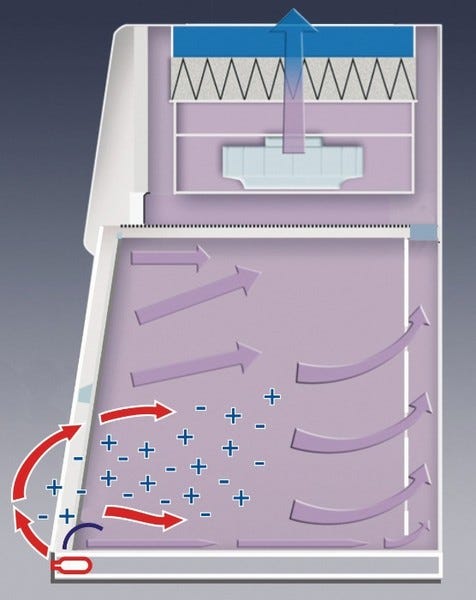

Polymerase chain reaction (PCR) is a common technique used in molecular biology to exponentially amplify a target region of DNA or RNA. PCR can turn a single piece of DNA into more than a million pieces in the matter of hours. Unfortunately, a single piece of contaminating DNA can also be amplified, making it extremely important that researchers work within a sterilized area that prevents cross contamination of samples.

PCR workstations were designed to minimize this problem. Adapted from laminar flow hoods, PCR workstations provide HEPA-filtered, sterile air within the hood. These hoods are outfitted with UV-C germicidal lights to disinfect the work surface when the hood is not in use. The lights are also placed on a timer to reduce the risk of UV exposure. In addition to its germicidal properties, UV-C light also causes breaks in strands of DNA that prevent the DNA from being amplified during PCR. Therefore, the UV-C light also serves to prevent carry-over contamination from previous experiments.

Explosion-Proof Hoods

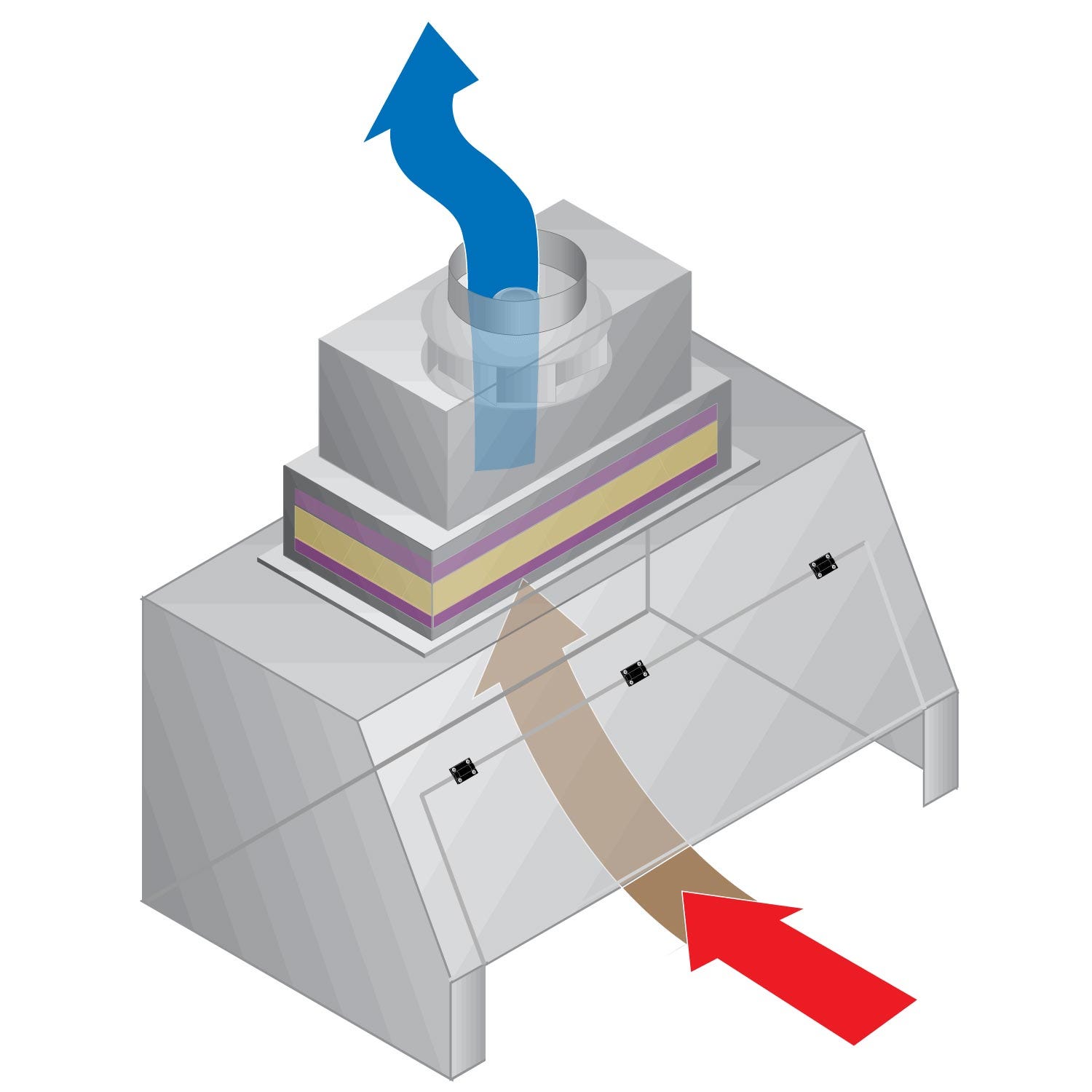

Explosion-proof hoods are a variation of either the laminar flow or exhaust fume hood, designed for work involving potentially flammable material. The conventional motor of the hood is replaced by an NEC Division I-rated non-sparking motor, mounted in a cast-iron, explosion-proof housing. In addition, the hood features an explosion-proof light, and all wiring is encased in filled rigid conduit.

These hoods bear an NEC sub-rating: Division I, Class 1 indicates suitability for use where flammable materials are generally present, and Division I, Class 2 indicates suitability for use when such materials are only intermittently present.

Balance Enclosures

Weighing dry powder chemicals is a routine laboratory task. Weighing procedures frequently result in some of the powder becoming airborne irritants – and potentially toxic threats – to lab personnel. Balance enclosures minimize this danger.

They are essentially ductless fume hoods with a few minor modifications. These negative pressure enclosures direct air from outside the hood through a HEPA filtration system before it is returned to the room. The HEPA filtration system is 99.99% effective in removing particles as small as 0.3 microns in diameter from the air, virtually eliminating the risk of personnel exposure. The front sash of the balance enclosure opens upward, allowing easy transfer of balances into and out of the enclosure.

Nanoparticle Enclosures

These enclosures are essentially balance enclosures that use an ULPA filter, which is 99.995% efficient in removing particles as small as 0.12 microns, to contain the much smaller particles generated during nanomaterial processing.

Can't find what you're looking for?Tell us what you need and we'll build it!