What is a Cleanroom?

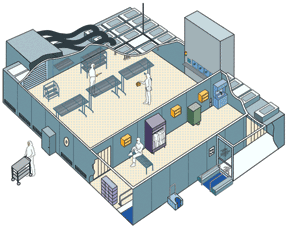

What is a cleanroom?A cleanroom is a specially designed environment where airborne particles, contaminants, and pollutants are controlled to extremely low levels. These facilities are essential in industries where even microscopic contamination can ruin products or processes. The goal is creating an environment where sensitive processes can occur without contamination that could cause defects, safety issues, or product failures.

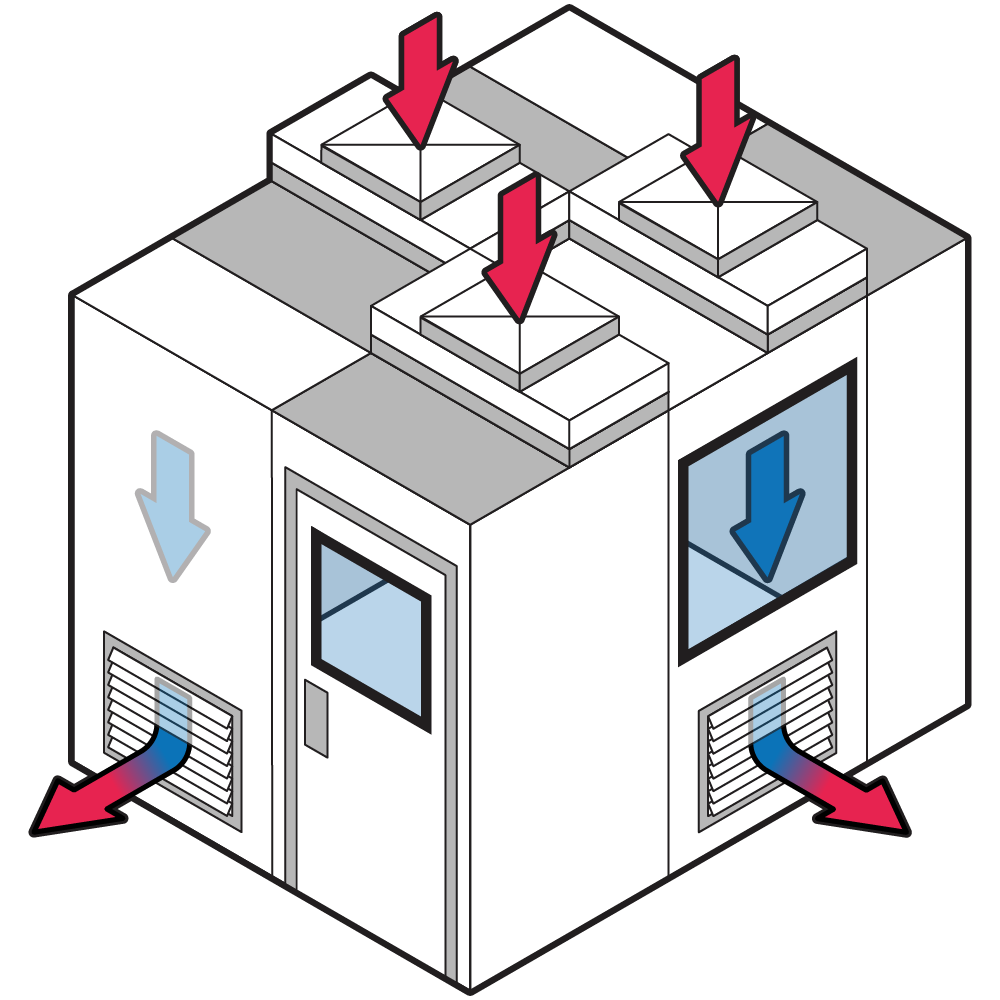

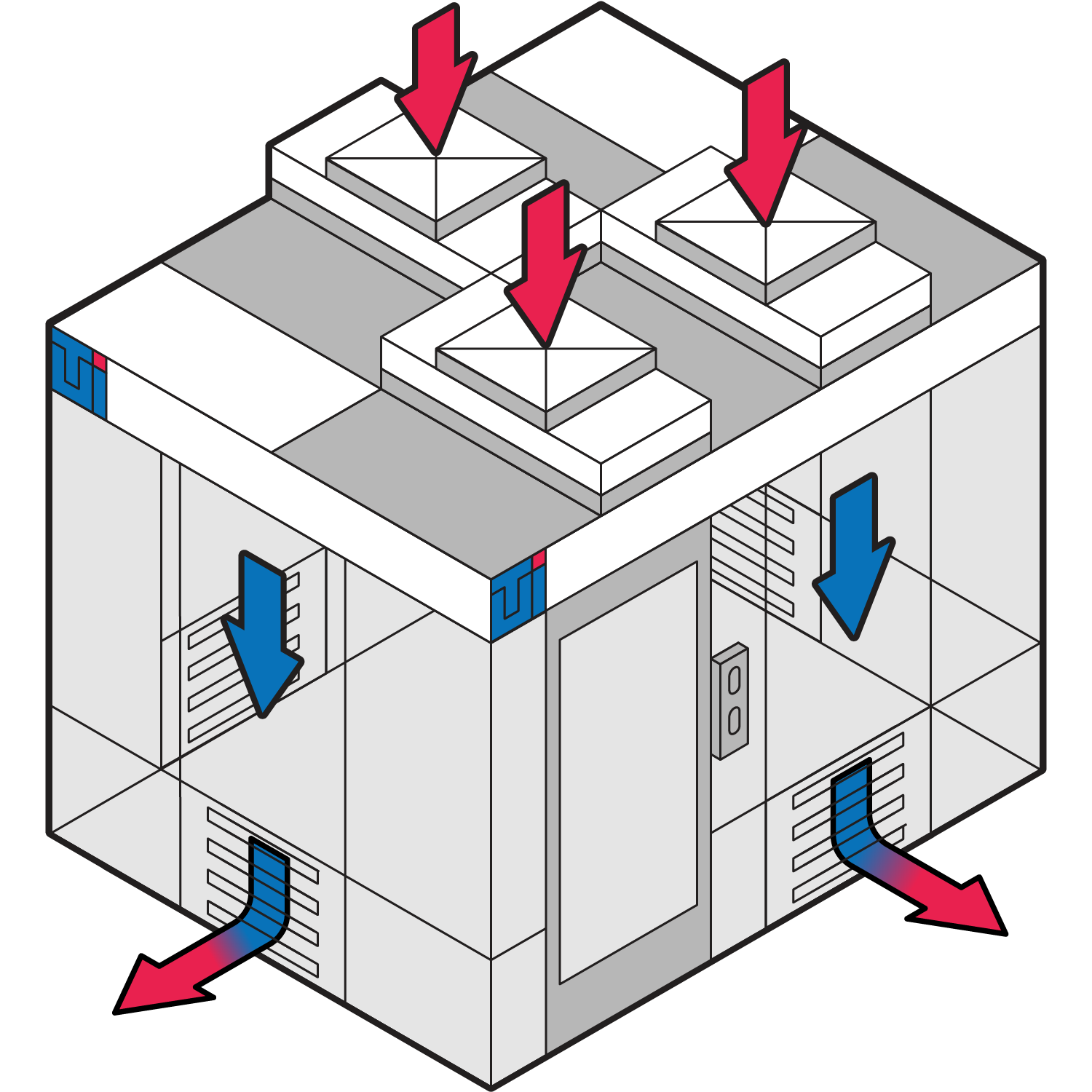

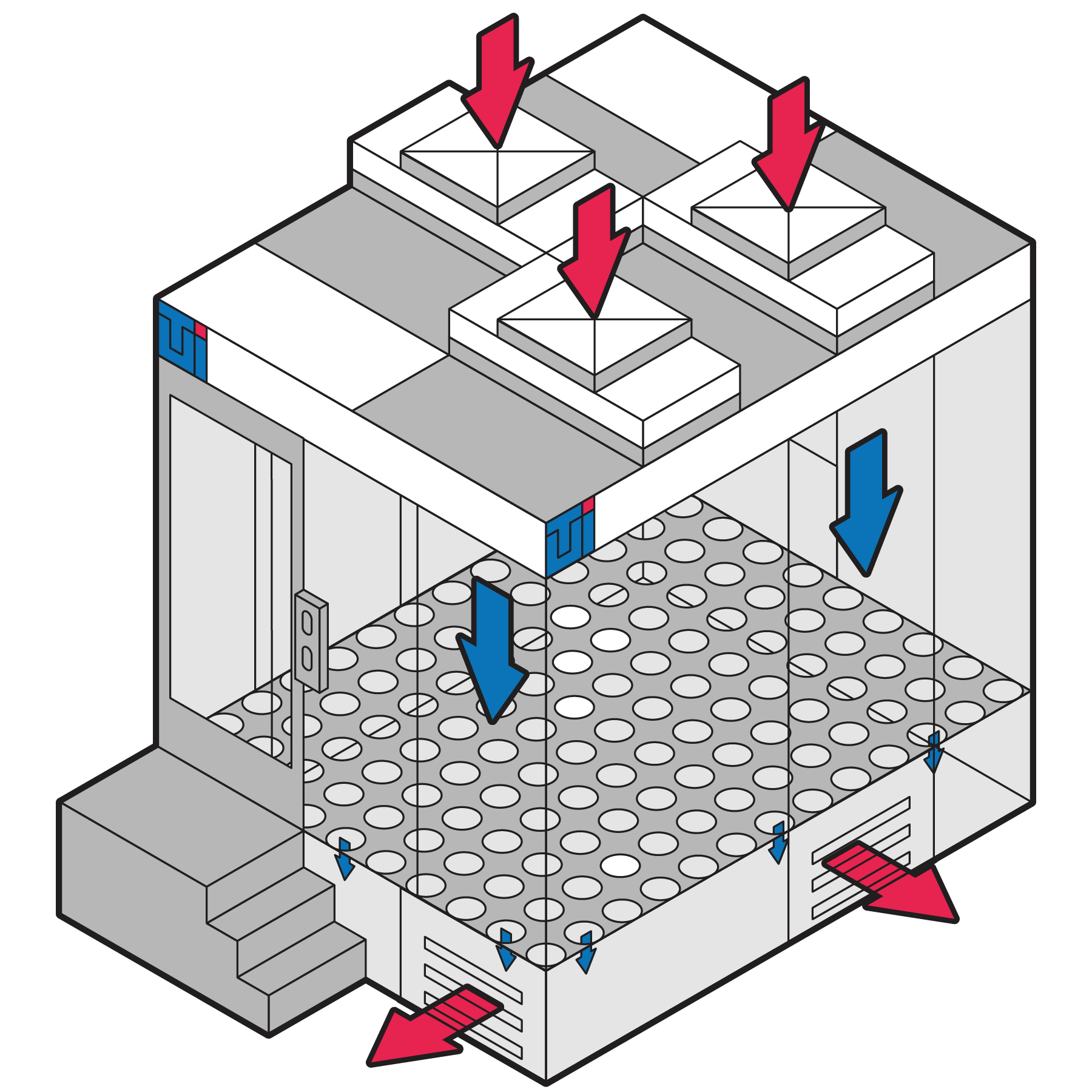

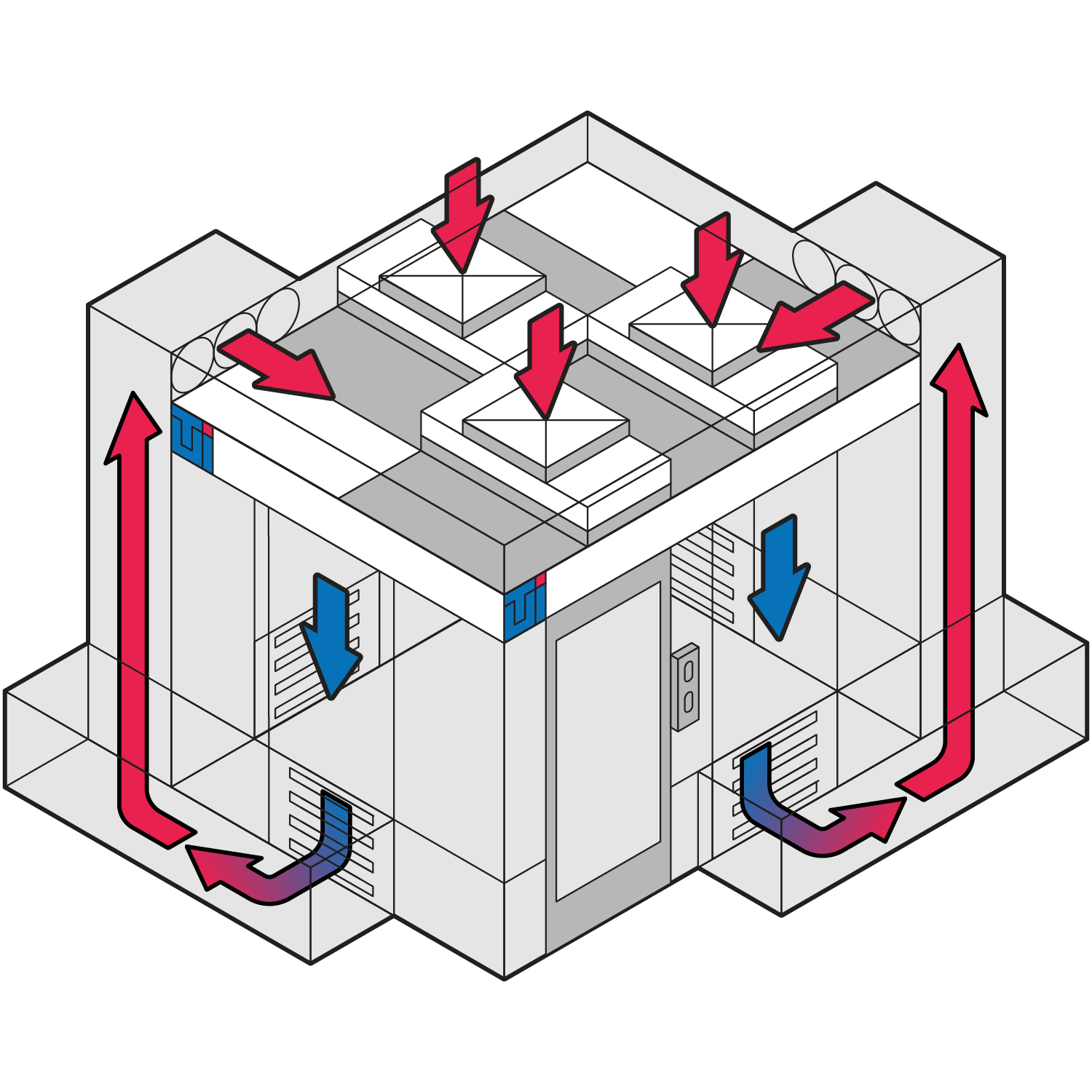

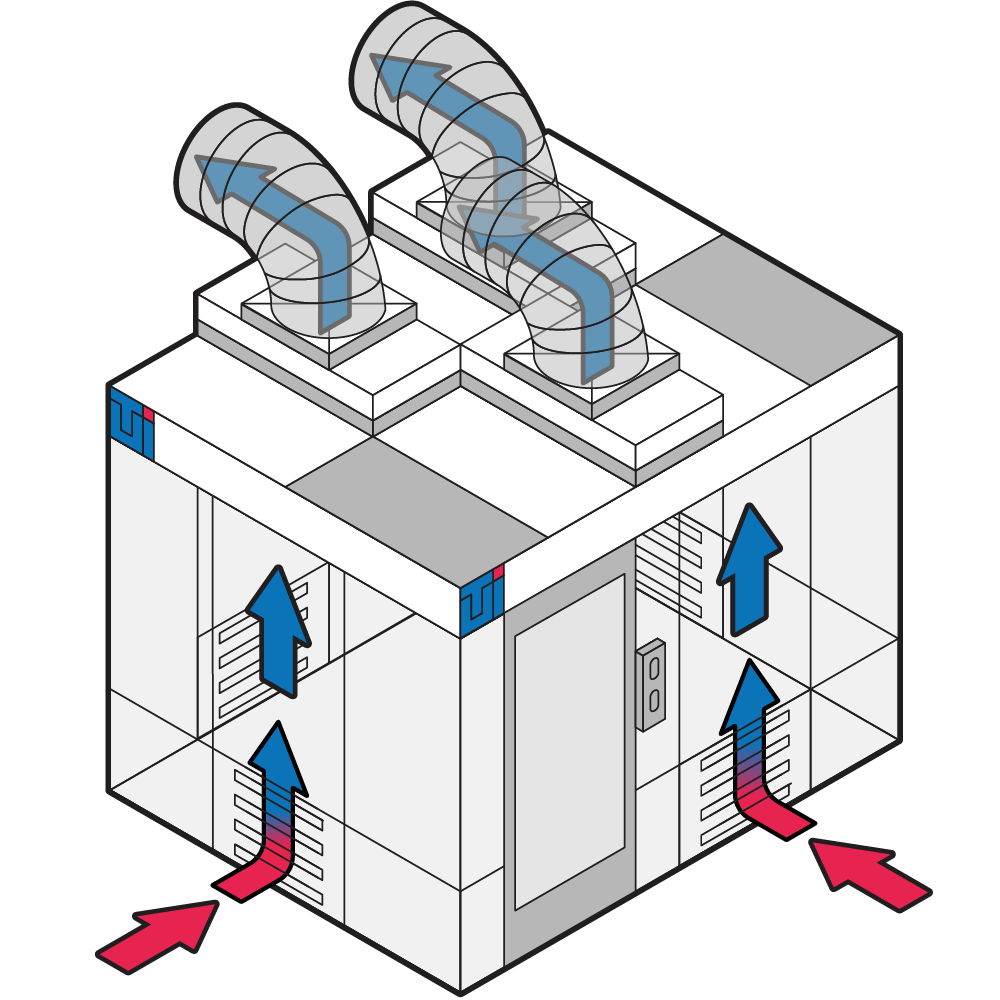

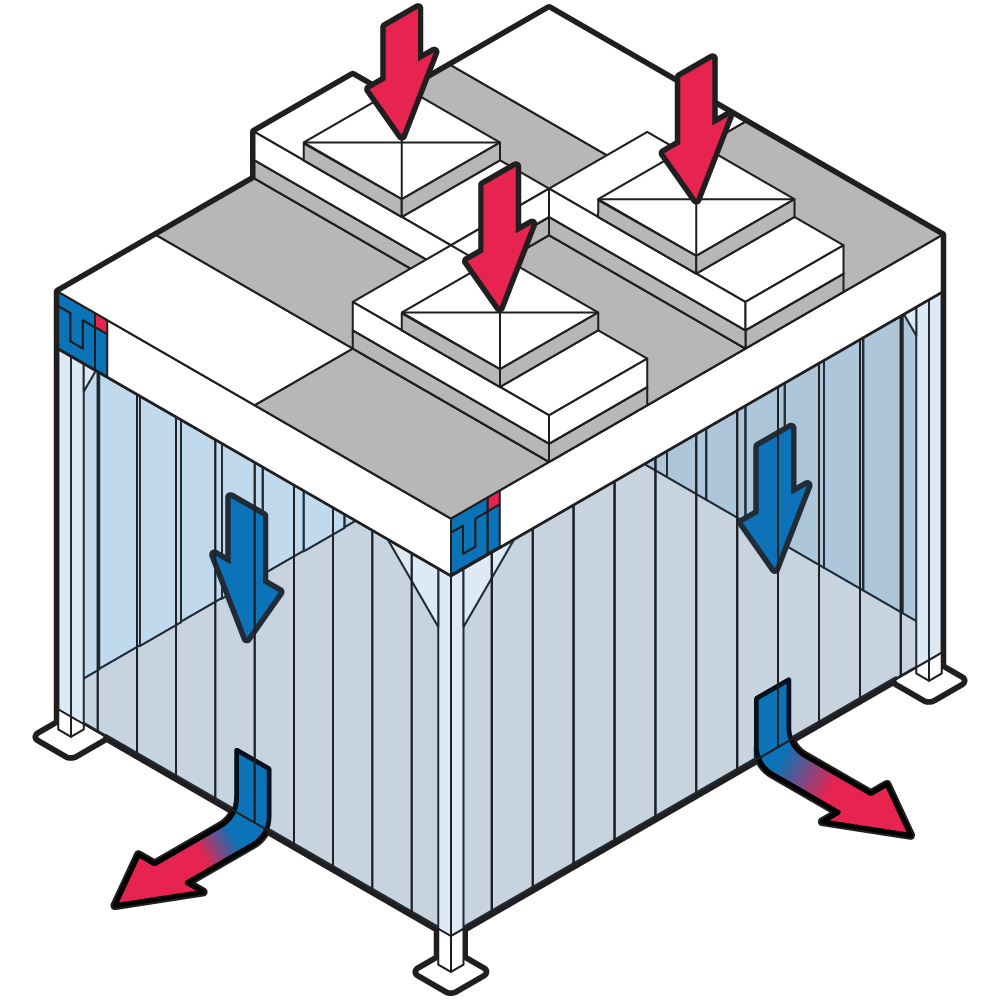

How Does a Cleanroom Work?The space uses sophisticated air filtration systems, typically with HEPA or ULPA filters, that continuously circulate and clean the air. Air flows in controlled patterns (often from ceiling to floor) to sweep contaminants away. Special materials, lighting, and surfaces are used to minimize particle generation and allow for regular disinfection and sterilization procedures.

Key Characteristics of a CleanroomCleanrooms maintain strict control over particle counts in the air, typically measured by particles per cubic foot or cubic meter. They're classified by cleanliness levels - for example, a Class 100 cleanroom allows no more than 100 particles (0.5 micrometers or larger) per cubic foot of air. The surfaces, walls, floors, and equipment are typically built from non-porous, smooth materials like stainless steel that can be easily cleaned and sterilized to control microbes and other contaminants.

Additional Cleanroom Controls:Beyond air quality, cleanrooms often regulate temperature, humidity, and pressure. Personnel must wear special clothing (bunny suits, gloves, shoe covers) and follow strict protocols when entering and working inside. Regular cleaning and sterilization schedules ensure microbial contamination remains controlled.

Cleanroom Classifications

| Class ISO 14644-1 (Federal Standard 209E) | Maximum Particle Concentration Per M3 .1µm|.2µm|.3µm|.5µm|1µm|5µm | Average Airflow Velocity m/s (ft/min) | Air Changes Per Hour | Ceiling Coverage | Application | Terra Cleanroom Design |

| ISO 8 (Class 100,000) | c|c|c|3,520,000|832,000|29,300 | 0.005 – 0.041(1 – 8) | 5 – 48 | 5 – 15% | Automotive Environmental Research Food Manufacturing | Hardwall Softwall BioSafe® Wall Panel System |

| ISO 7 (Class 10,000) | c|c|c|352,000|83,200|2,930 | 0.051 – 0.076(10 -15) | 60 – 90 | 15 – 20% | Nutraceutical Development Drug Compounding Cell Culture | Hardwall Softwall BioSafe® Wall Panel System |

| ISO 6 (Class 1,000) | 1,000,000|237,000|102,000|35,200|8,320|293 | 0.127 – 0.203(25 – 40) | 150 – 240 | 25 – 40% | Medical Device Life Science Operating Rooms | Hardwall BioSafe® Wall Panel System |

| ISO 5 (Class 100) | 100,000,|23,700|10,000|3,520|832|d, e, f | 0.203 – 0.406(40 – 80) | 240 – 480 | 35 – 70% | Nanofabrication Pharmaceutical Filling Optics | Hardwall BioSafe® Wall Panel System |

| ISO 4 (Class 10) | 10,000|2,370|1,020|352|83|d | 0.254 – 0.457 (50 – 90) | 300 – 540 | 50 – 90% | Aerospace | BioSafe® Wall Panel System |

| ISO 3 (Class 1) | 1,000|237|102|35|d|e | 0.305 – 0.457 (60 – 90) | 360 – 540 | 60 – 100% | Semiconductor Microelectronics | BioSafe® Wall Panel System |

| ||||||

Modular Cleanroom Selection Guide

Terra Universal designs, builds, and installs modular cleanrooms for every application. Unique in the industry, we offer a vast selection of prefabricated and in-stock modular cleanrooms, available to ship from our California manufacturing facilities within 1 to 3 business days.

Because they can be built and installed in a fraction of the time associated with brick-and-mortar clean rooms, modular cleanrooms are ideal for fast ramp-up projects or short production cycles that may not merit the expense and delay of a conventional room.

Not sure what you need? Our Cleanroom experts are ready to help! Click here to receive a quote within 24 hours.

BioSafe® Cleanroom and Wall Panel System

The most effective design for bio-tech and pharmaceutical applications.

- ISO 3 – 8 aseptic design for biomedical and pharma applications.

- Compliant with ISO-14644, GLP, ASTM, IEST, and cGMP grades A, B, C, and D requirements.

- Seamless wall panel system. Fully monolithic and flush-mount connecting wall panel system (not a panel-post system with gaps and ledges). Eliminates crevices where microbes colonize.

- Sealed joints with cold welded seams.

- Core Material: Aluminum honeycomb or foam.

- Shell Material: uPVC, 316 stainless steel or powder-coated steel walls.

- Configure as a positive- or negative-pressure room, with A/C and humidity control.

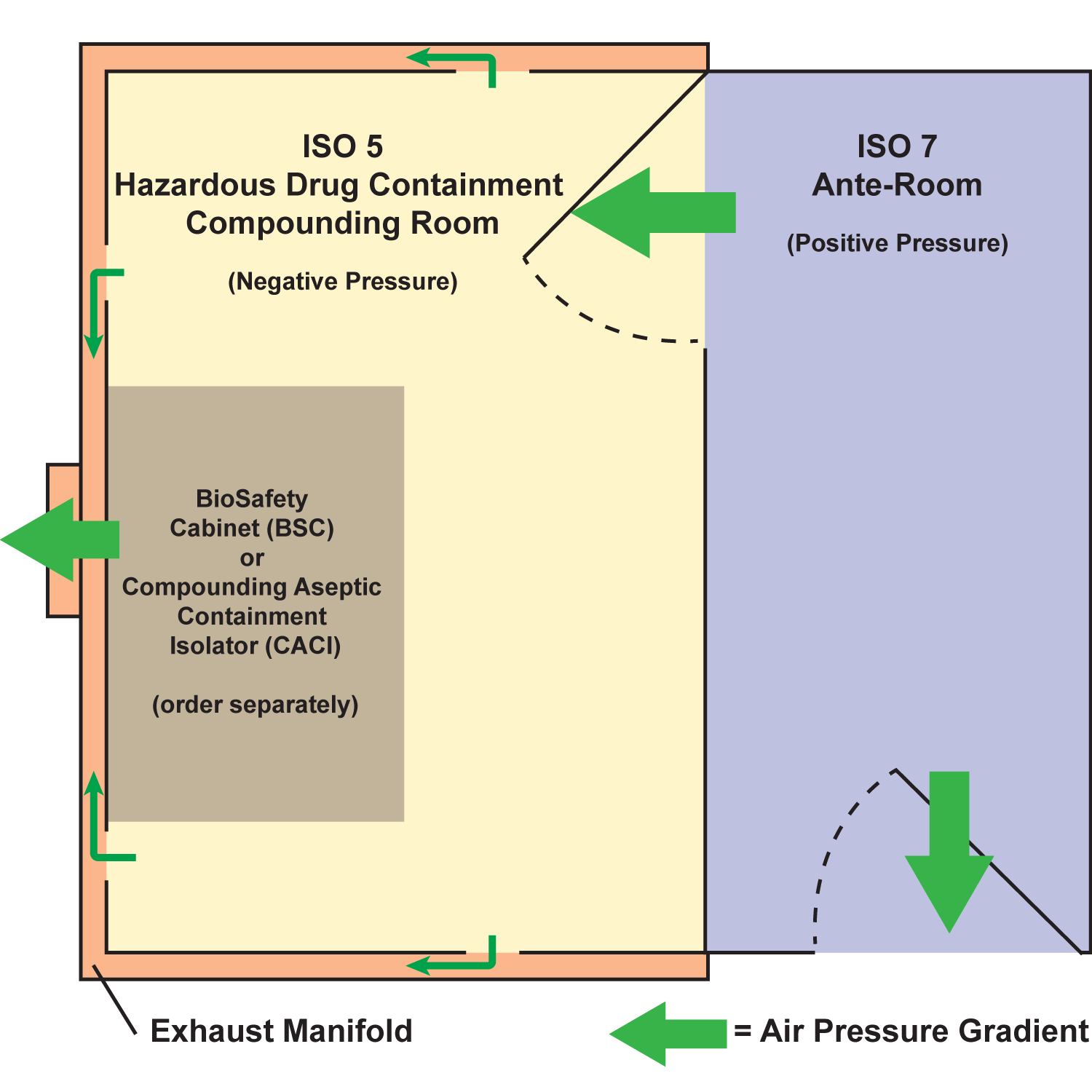

USP 797/800 Sterile Compounding Cleanrooms

- Designed for USP 797 Sterile drug compounding and USP 800 hazardous drug compounding.

- Turnkey USP 797/800 compliant configurations with pre-designed components. ISO upgrades meet more rigorous DQSA 503(b) requirements.

- USP 797 sterile compounding cleanrooms feature positive-pressure ISO 8 anteroom that opens to a positive-pressure ISO 7 sterile compounding room.

- USP 800 cleanrooms feature positive-pressure ISO 7 anteroom that opens to a negative pressure ISO 5 hazardous compounding room.

- Stainless steel or plastic walls.

Hardwall Cleanrooms — Full-View Plastic Panel

- ISO 5 – 8. Ideal for Aerospace, Semiconductor, USP797/800 Pharmaceutical compounding.

- Pre-fabricated frame, wall panels, and ceiling system.

- Rapid deployment, highly scalable, easily expandable.

- Pre-configured cleanrooms in-stock and ready to ship within 1-3 days.

- All-steel support frame for strength and easy installation - requires no external bracing.

- Interchangeable wall panels: Select transparent acrylic, static-dissipative PVC, polycarbonate, chemical resistant polypropylene, fire-resistant FM 4910 panels.

- Configure as a positive- or negative-pressure room, with A/C and humidity control.·

- Explosion-proof cleanroom designs meet NEC requirements for Class I, Division 1 hazardous locations.

Raised-floor Cleanrooms

Ideal for applications that require raised flooring for true laminar flow. Double-wall structure allows air to circulate through the inter-wall plenum, increasing filtration and A/C efficiency.

Recirculating Cleanrooms

Recirculating cleanrooms improve efficiency by cycling pre-cleaned air through HEPA filters, which further reduces airborne contaminants and prolongs lifespan of the HEPA filters. This also makes it possible to achieve stricter cleanliness classifications, such as ISO 5, while maintaining consistent environmental control.

Negative-Pressure and Ventilation Cleanrooms

Ideal for safe removal of fine powders or chemical vapors. Ceiling exhaust fans draw air through HEPA filters on the ceiling. Inlet filters ensure a clean working environment. Horizontal and vertical exhaust airflow designs available.

Softwall Cleanrooms

- ISO 7 – 8.

- Lowest cost cleanroom design.

- Pre-fabricated frame, curtain panels, and ceiling system.

- Pre-configured cleanrooms in-stock and ready to ship within 1-3 days.

- Rapid deployment, highly scalable, easily expandable.

- All-steel support frame for strength and easy installation - requires no external bracing.

- Explosion-proof cleanroom designs meet NEC requirements for Class I, Division 1 hazardous locations.

Terra Universal's Value Advantage

Facility Optimization — Create the production environment you require without the expense or disruption of a major fab upgrade! Expand or reconfigure as your requirements change.

Unsurpassed Cleanliness — Filtration and ventilation efficiency required to meet the most rigorous cleanliness standards. Independently certified Class 1.

Hardwall, Softwall, and Hybrid Designs — A style for every requirement, schedule, and budget!

Comprehensive Environmental Controls — Over particulates, humidity, temperature, and ESD (electrostatic discharge)

Industry-leading Quality — Over 50 years of engineering and manufacturing experience provide standardized quality you can count on.

Certified Designs and Fabrication Techniques — Terra Universal has received independent certification as a Cleanroom Manufacturing Specialist.

Delivered to Your Production Schedule — Terra Universal understands the critical importance of timely delivery and works closely with you to accommodate tight schedules. Expanded QuickShip configurations provide a wide variety of "need it now!" cleanrooms.

Turnkey Purchasing: Terra Universal's Value Advantage

The leader in Critical Environment Solutions®, Terra also designs, manufactures, and stocks comprehensive lines of cleanroom components and equipment, including: cleanroom doors and windows, pass through chambers, laminar flow and fume hoods, biosafety cabinets, desiccator cabinets, glove box isolators, cleanroom furniture, and other laboratory equipment.

Can't find what you're looking for?Tell us what you need and we'll build it!