When storing sensitive materials in a desiccator cabinet, unnecessarily high gas flow into the chamber or misalignment of the cabinet can lead to costly nitrogen waste. Positive pressure within a desiccator is meant to push unwanted moisture-dense air through the cabinet’s release valves and prevent the ingress of moisture-laden air. This continuous process leaks a small portion of gas, since desiccators are not 100% air-tight systems. Let’s consider three of the top reasons why your desiccator may be leaking:

Cabinet Misalignment

10-chamber desiccator

A common issue you may face when first installing plastic 18desiccator cabinets, such as Terra’s ten-chamber unit shown here, is misaligned cabinet doors. Due to the flexibility of plastic and the movement involved with product shipment, plastic desiccator doors are subject to minor fluctuations. Fortunately, doors can easily be realigned in less than a minute!

Before checking the alignment of your desiccator doors, ensure that the desiccator is installed on an evenly leveled surface, whether it be on a stand (shown in image) or on top of a work station. If a desiccator is not properly leveled, its doors may fall out of alignment and risk leaking gas.

If you notice that the doors on your multi-chamber cabinet are not closing evenly, follow these quick steps to ensure that each door latch engages the retaining catch at the proper position. Be sure to empty your desiccator of any sensitive materials before performing this maintenance.

- Open all of the cabinet doors.

- Starting from the bottom of the cabinet, close the doors so that their latches are centered in corresponding catches.

- Once all of the doors are closed, they will work together to hold the cabinet in the correct position.

If these simple steps do not correct the doors’ alignment, it may be best to call your manufacturer for further assistance.

Gasket Wear & Tear

Gasket in corner of desiccator door

High quality desiccator doors often feature a mechanically installed gasket to minimize leaks without the outgassing or creeping common on adhesive gaskets. Like any mechanism used repeatedly, gaskets will naturally loosen over time, whether sealed mechanically, or with adhesive. As the gasket loses its tight seal to the door, the desiccator may begin leaking gas, thus increasing the need for gas flow. This may not be a serious issue for applications purging compressed air into the desiccator chamber, although it could be costly for those requiring nitrogen.

The best solution to gasket degradation is to replace the desiccator door with a new door that also has a mechanically applied gasket. This is the preferred practice to ensure ultimate quality and effectiveness for your desiccator. If use of an adhesive gasket is permissible, a replacement adhesive gasket can be applied as a more economical option.

Excess Gas Pressure

As mentioned previously, it is normal for small amounts of gas to leak out of a desiccator from the strain of constant positive pressure. Without the help of control systems, your desiccator may be receiving too much gas flow. Without an adequate number of release/bleed valves in the desiccator cabinet, the excess gas exceeds the pressure limits, forcing gas to leak from the desiccator doors. This problem is common in larger multi-chamber cabinets that have only one release valve per chamber.

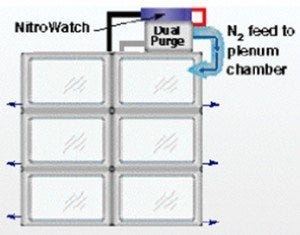

Gas flow using Dual Purge & NitroWatch controls

When this occurs, the simplest solution is to decrease the gas flow. A more reliable and accurate solution would be to install an automatic gas control system, such as Terra’s Dual Purge™ and NitroWatch® Systems. These devices can be programmed to regulate desiccator gas pressure and deliver a gas flow only when it is required to maintain a selectable low-humidity set point. Once programmed, these systems maintain pressure and humidity set points based on the purge delay or recovery time that you require. Adding a relief/bleed valve in each desiccator chamber also increases efficiency and reduces waste.