Boosting Yields through Vibration Control

In an age of rapidly shrinking component geometries, your investment in vibration control today will be even more important tomorrow

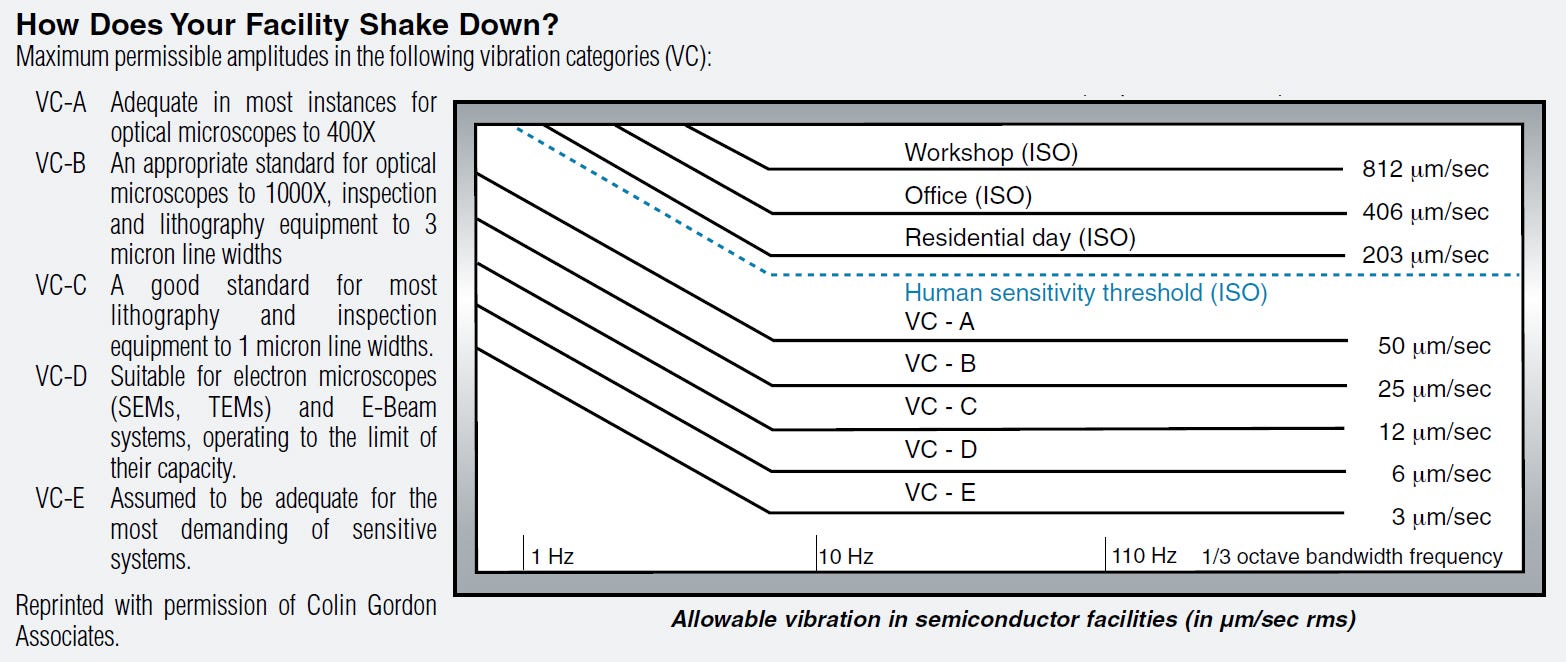

As manufacturers involved in lithography, surface profilometry, metrology, biotechnology, and other critical operations have found, vibrations are a potentially disastrous threat to precision and throughput.

Vibrations are generated by traffic, footfall, air handling equipment, and other conditions that exist in the vicinity of virtually every manufacturing facility.

Even though a production or metrology tool may include a vibration isolation system, the fab floor may not meet the equipment’s floor specification. Or vibrations experienced at the fab floor may push an existing tool beyond its original resolution specification. Or disturbance levels deemed acceptable at one time may escalate suddenly and unexpectedly—causing serious problems.

Disturbing Consequences!

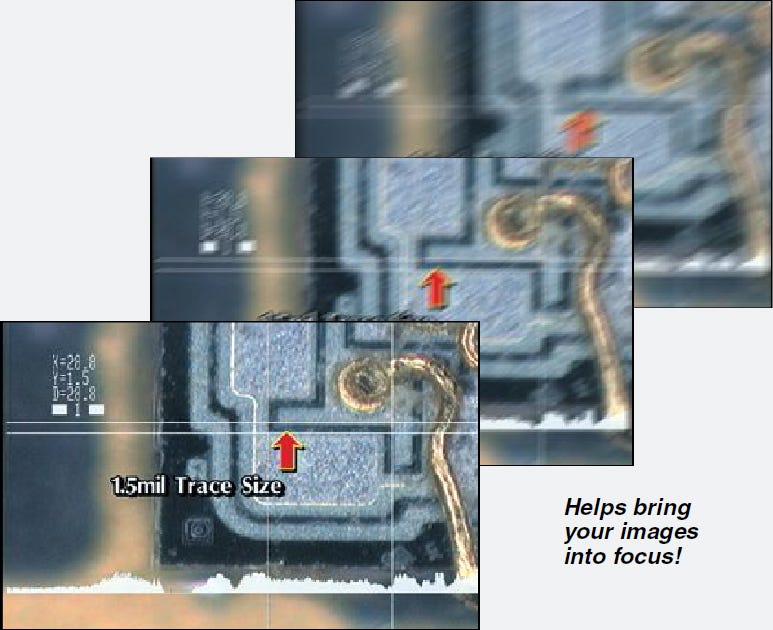

In the most severe cases of environmental disturbance, high-precision operations become impossible. Without the ability to zero in on precise locations on a sample surface, an operator cannot complete critical functionality tests, obtain required resolution, or perform microinjections and other delicate procedures.

In other cases, momentary disturbances can compromise operations without the operator’s knowledge. For example, a brief set of vibrations caused by unusually heavy street traffic can have disastrous consequences on an automated step-andrepeat lithographic exposure, involving hundreds of discrete parts that will have to be reworked or scrapped. To make matters worse, this damage may not be detected until after further processing operations have been completed—compounding an investment in degraded components.

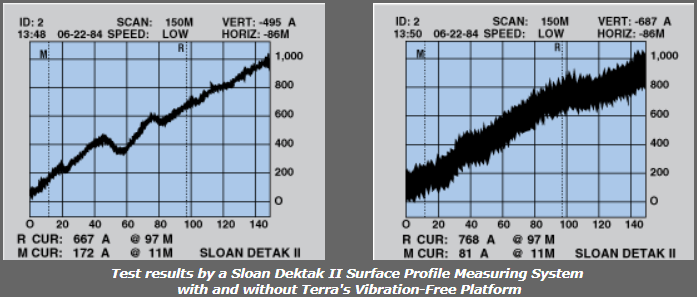

Another consequence of environmental disturbances is felt on a more visceral level: they literally may be making your operators sick! Persistent viewing of blurred, shaking objects at high magnifications causes nausea, headaches, and fatigue, which take a heavy toll on performance and throughput.

Passive and Active Vibration Control

Vibration Control is essential for precision test and measurement of production processes and the research of phenomena with dimensions in the nanometer (and even Angstrom) size range. Successfully meeting this level of stability requires extremely precise alignment of system components, which is best accomplished by combining three strategies:

- A rigid system structure: Keeping a high stiffness-to-mass ratio of the instrument and the support structure results in better resistance to both on-board and environmental vibration.

- A stable floor: Floor vibration is by far the most important environmental factor in determining system performance. Especially in older buildings built to less stringent stability specifications, vibration from a wide variety of sources may be a significant problem. In such cases, the floor may need to be reinforced.

- Supplemental passive or active vibration isolation where needed: If the floor exceeds adequate stability for the desired level of performance, a supplemental vibration isolation system may be required.

Applications: Enhanced PerformanceThrough Vibration Isolation

- High Resolution Microscopes

- Scanning Electron Microscopes

- Scanning Probe Microscopes—such as AFM’s and STM’s

- Transmission Electron Microscopes

- Commercial Interferometers

- Surface Profilometers

- Photolithography Exposure Illuminators

- Metrology Inspection Systems

- Ion Implanters

- Probe Stations

Passive Vibration Isolation

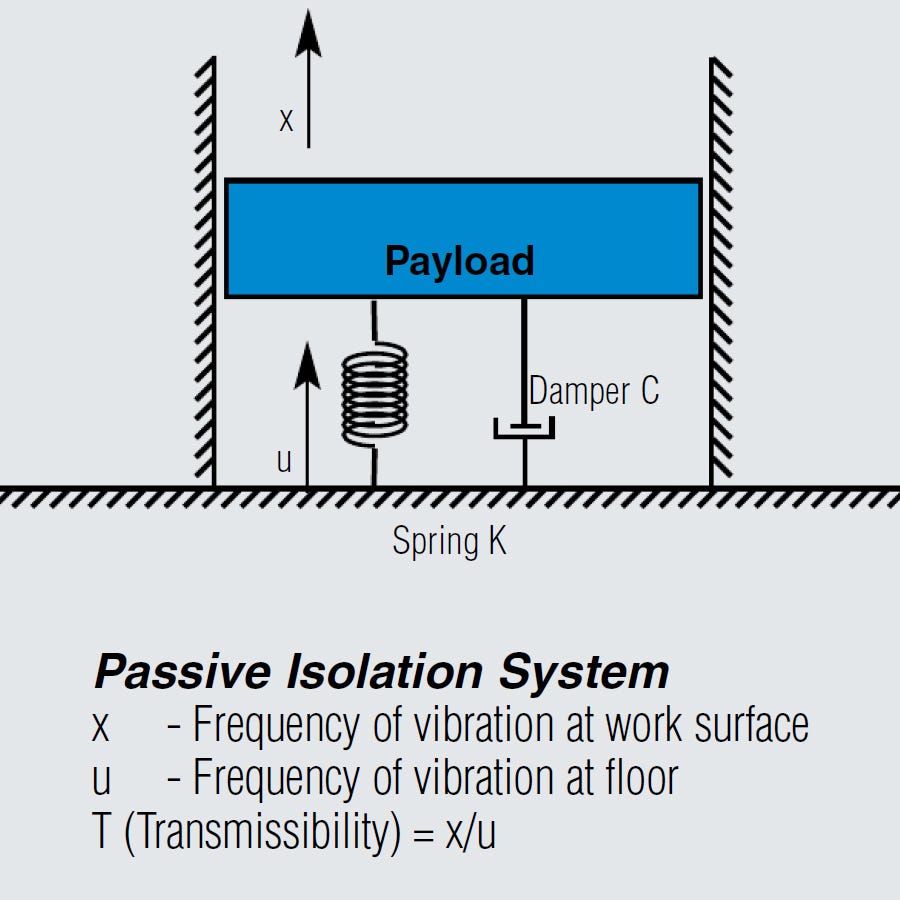

The most common type of vibration isolator is the pneumatic isolator, which contains a sealed and pressurized air volume and movable piston. A rolling diaphragm membrane provides an airtight seal between the isolator and the piston. Compressed air pushes against the piston to support the system static load. Damping is provided by forcing air to move between chambers through one or more small orifices and/or a pendulum rod within a viscous damper.

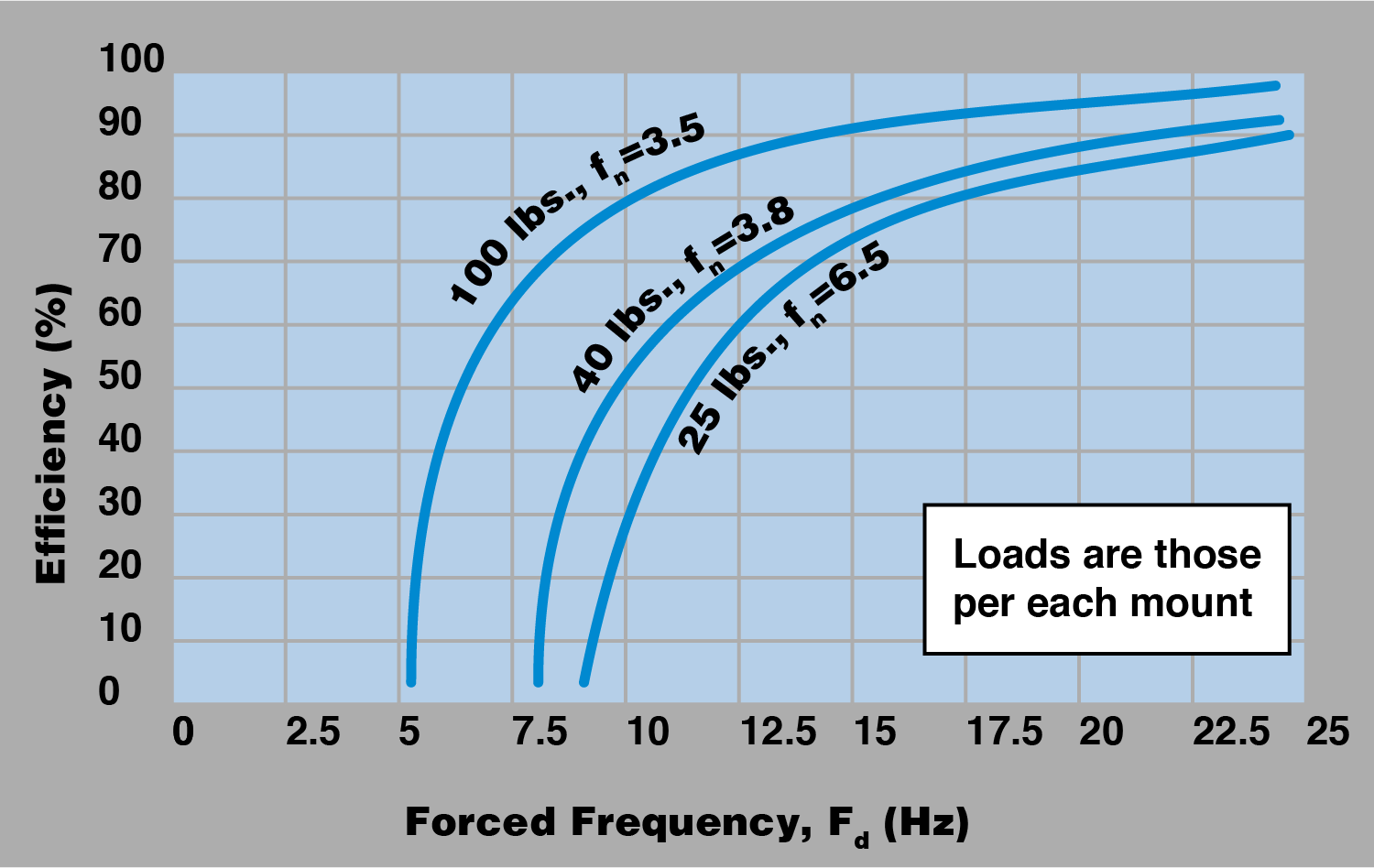

Simply stated, the key to isolating vibration is to develop vibration isolators that attain the lowest possible natural frequency with the best isolation possible. The lower the natural frequency, the greater the ability of the isolation table to resist a disturbing frequency (resulting from loud noises, traffic, falling objects, etc.).

Natural frequency is the rate of movement (in cycles per second) at which a massspring system will vibrate if it is disturbed. The damping mechanism in the system will eventually damp out these oscillations.

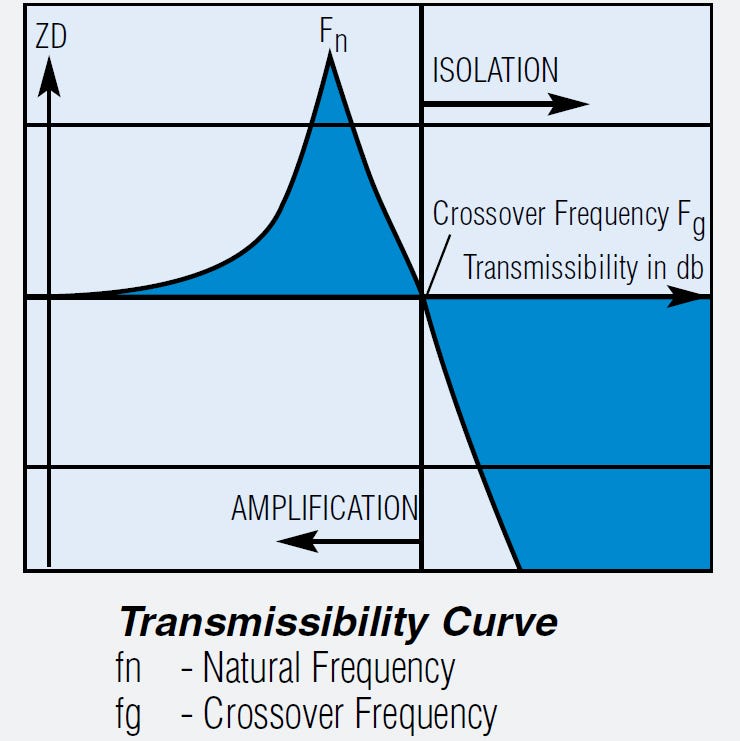

As long as the disturbing frequency is higher than the natural frequency, the surface will isolate the vibration. When disturbing frequencies approach and then fall below the natural frequency, however, the isolators in the vibration table will amplify the disturbing frequency, increasing the vibration of the work surface.

Vibration isolation effectiveness is demonstrated graphically by a transmissibility curve which plots the ratio of system motions to ground motion as a function of frequency. In the transmissibility curve shown, the crossover frequency is the frequency at which the motion of the isolated system is the same as the floor motion (transmissibility = 1).

Any disturbing force with a higher frequency will be isolated; the pneumatic isolator will transmit only a small fraction of the floor vibration to the isolated system. This isolation efficiency approaches 99.9%, depending on the load and the disturbing frequency.

Any disturbing force with a lower frequency will be amplified, although this amplification can be minimized through proper engineering of the damping mechanism. This low frequency amplification can be eliminated, and additional vibration isolation achieved, with an active vibration control system (see below).

For optimal results, then, the desirable characteristics of a pneumatic isolator are a low natural frequency, a low amplification at resonance, and a fast roll-off of vibration transmission at higher frequencies. These are precisely the characteristics engineered into our line of passive vibration isolation tables and platforms.

In addition to standard Vibration-Isolation Workstations, Terra offers stand-alone isolators, platforms, and pedestals designed specifically for common semiconductor processing and inspection equipment operating in a cleanroom environment.

BP Modular Block Platform Designed specifically for integration into raised cleanroom floor.

Call for information on a solution to environmental disturbances in your facility!

Active Vibration Control

The passive vibration-isolation system described above is generally effective at isolating floor vibrations at higher frequencies, but it does nothing to isolate payload-generated vibrations. Automatic XY stages, for example, create vibrations that compromise readings. Likewise, fans, motors, and valves that are directly mounted to the payload create vibrations that cannot be isolated by a passive system.

Active isolation addresses these shortcomings while providing maximum isolation for low frequency vibration (0.7 - 30 Hz). A typical active vibration control system consists of motion sensors and force or displacement actuators, which produce counteracting forces designed to cancel payload vibration. By permanently mounting the motion sensor to the payload, the controller receives all the residual vibration signals from any source, regardless of their origin: floor vibration, sound pressure waves, etc. This innovative active-control system is known as a real-time feedback controller, with optional stage and ground feedforward control.

Applying feedforward control to XY stages requires an interface between the stage controller and the active system controller, producing outstanding performance and decreasing settling times by a factor of 200 (typically). This design virtually eliminates the long settling time after stage movement, which is characteristic of passive vibration systems, greatly improving throughput.

| Period | Photo Line | Registration | Inspection |

|---|---|---|---|

| 1975 - 1980 | 7 to 10 microns | 0.7 to 1 micron | 0.1 micron |

| 1980 - 1985 | 2 to 7 microns | 0.2 to 0.7 microns | 0.07 micron |

| 1985 - 1990 | 0.7 to 2 microns | 0.07 to 0.2 microns | 0.02 microns |

| 1990 - 1995 | 0.03 to 0.07 micron | 0.3 to 0.7 microns | 0.007 micron |

| Current - Future | 0.1 to 0.3 micron | 0.01 to 0.03 micron | 0.0001 micron (10Å) |

Can't find what you're looking for?Tell us what you need and we'll build it!