BioSafe® Universal Benchtop Hoods Overview

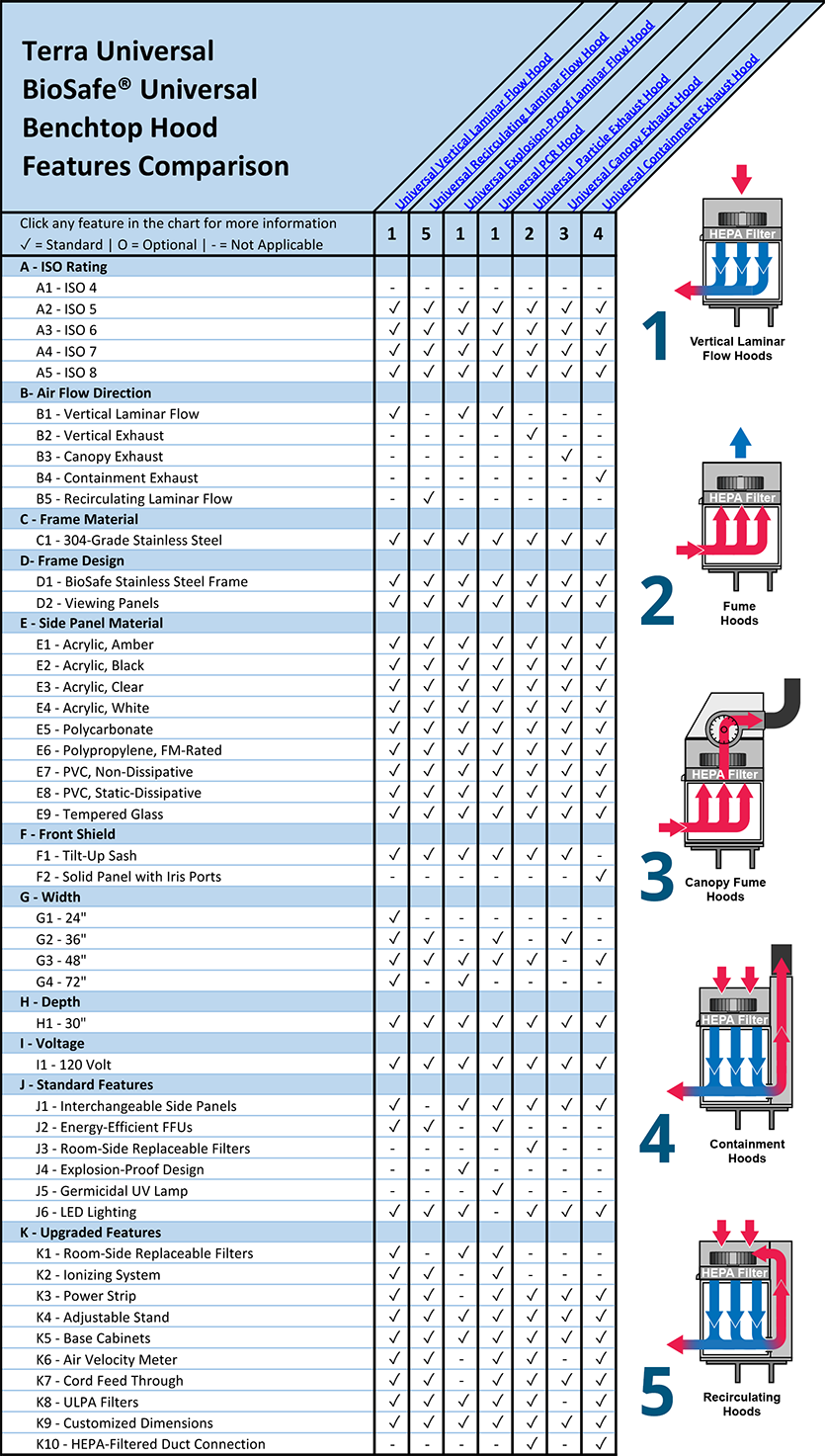

BioSafe® Universal Benchtop Hoods are a UL-Listed product manufactured by Terra Universal. "Universal" flow hoods designate a modular design that can achieve seven different configurations from a single flow hood.

Seven Modular Configurations, One Benchtop Flow Hood

The modular flow hood components allow modification of a single flow cabinet to achieve virtually any microenvironment including vertical or horizontal footprints, positive or negative pressure flow, air recirculation, particulate containment, or fume handling. Beyond initial system integration, BioSafe® Universal Hood provides the flexibility to reconfigure the hood on-site to adapt to changing application requirements.

Components Ready to Ship in Approximately One Week

When additional components are required to update the flow hood configuration, orders are fulfilled directly from Terra's California manufacturing facilities. On-hand, on-location inventory means components are ready-to-ship approximately one week after order release.

BioSafe® Universal Flow Hood Construction

BioSafe® Universal Flow Hood construction includes a BioSafe® stainless steel frame designed free of cracks and crevices for easy disinfection. The 304-grade stainless steel frame is rigid, durable, low bio-burden, and resistant to cleaning agents, biocides, acids, and solvents.

BioSafe® Universal Flow Hood Applications

For hoods housing microscopy systems or sensitive analytical equipment, mitigating vibration is of primary importance. Universal hoods are equipped with low-vibration, low-noise (40 decibels), energy-efficient smart WhisperFlow filter fan units with infinitely variable speed control. Terra’s smart FFUs generate less heat, draw less power, and produce higher airflow than conventional, industry-standard models.

The seven distinct hood configurations are detailed below.

BioSafe® Universal Benchtop Vertical Laminar Flow Hood

BioSafe® Universal Vertical Laminar Flow Benchtop Hoods provide a compact, easy-to-sterilize design that converts any lab bench into an ISO 5 (Class 100) environment. A ceiling-mounted, HEPA-filtered WhisperFlow fan unit provides a steady stream of micro-filtered air vertically across the work surface toward the front exit sash. The stainless steel hood frame is free of cracks and crevices where microbes collect.

The BioSafe® system protects items in the work zone - whether samples or instruments – from contamination, but does not protect operators from exposure to hazards, toxins, or odors.

The turnkey system includes a hood frame, low-noise (40 decibels) adjustable speed blower, HEPA filter, LED lighting, and an operation status indicator. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Recirculating Laminar Flow Hood

BioSafe® Universal Benchtop Recirculating Laminar Flow Hoods include a back plenum, with adjustable baffles, to divert air from the work zone through a vertical channel toward the ceiling-mounted fan unit, which directs air through a HEPA filter back into the work area. As recirculating flow hoods achieve a closed-loop system, the filter life span is significantly longer than standard single-pass flow hood designs. A ceiling-mounted, HEPA-filtered fan unit provides a steady stream of micro-filtered air vertically across the work surface toward the back plenum. The stainless steel hood frame is free of cracks and crevices where microbes aggregate.

The BioSafe® system protects items in the work zone - whether samples or instruments – from contamination, but does not protect operators from exposure to hazards, toxins, or odors. The turnkey system includes a hood frame, whisper quiet (40 decibels) adjustable speed blower, HEPA filter, LED lighting, and an operation status indicator. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Explosion-Proof Laminar Flow Hood

BioSafe® Universal Benchtop Explosion-Proof Laminar Flow Hoods are designed for work in areas where there is a risk of ignition due to flammable fumes or explosive dust. All electrical components - fan motor, LED lights, and wiring - are rated compliant for Class I, Division 1, Groups C & D and Class II, Division 1, Groups F & G for hazardous locations. All wiring is encased in a steel conduit to protect against exposure to fumes, pellets, or dust.

A ceiling-mounted, HEPA-filtered WhisperFlow fan unit provides a steady stream of micro-filtered air vertically across the work surface toward the front exit sash.

The BioSafe® system protects items in the work zone - whether samples or instruments – from contamination, but does not protect operators from exposure to hazards, toxins, or odors. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop PCR Vertical Flow Hood

BioSafe® Universal Benchtop PCR Hoods provide an ISO 5-compliant environment for nucleic acid amplification, sample prep, reagent storage, and liquid handling. The hood includes a ceiling-mounted WhisperFlow fan filter unit that provides a steady stream of HEPA-filtered air vertically across the work surface toward the front exit sash. As prevention of sample cross-contamination is paramount, the hood is equipped with a germicidal UV lamp that emits ultraviolet light across the work surface to inhibit microbial growth.

The BioSafe® system protects items in the work zone - whether samples or instruments – from contamination, but does not protect operators from exposure to hazards, toxins, or odors.

The turnkey system includes a hood frame, low-noise (40 decibels) adjustable speed blower, HEPA filter, and UV lighting. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Particle Exhaust Hood

BioSafe® Universal Benchtop Particle Exhaust Hoods vent air away from the work area, and the operator, through a ceiling-mounted negative-pressure blower and a HEPA filter before safely releasing the air back into the ambient environment. The filtration system does not include a charcoal filter, so this hood is designed for particle containment, not fume containment, applications.

Vertical exhaust hoods are configured to protect the operator from exposure to hazards, toxins, or nuisance odors, but they do not protect the work area from contaminants. The stainless steel hood frame is free of cracks and crevices where microbes aggregate and colonize.

The turnkey UL-listed system includes a hood frame, whisper quiet (40 decibels) adjustable speed blower, HEPA filter, and LED lighting. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Fume Exhaust Hood

BioSafe® Universal Benchtop Fume Exhaust Hoods vent air away from the work area, and the operator, through a ceiling-mounted negative-pressure blower and a filter stack before safely releasing the air back into the ambient environment. The two-stage filtration system is composed of a charcoal filter for fume vapor containment and a HEPA filter for particle containment.

Vertical exhaust hoods are configured to protect the operator from exposure to hazards, toxins, or nuisance odors, but do not protect the work area from contaminants. The stainless steel hood frame is free of cracks and crevices where microbes aggregate.

The turnkey UL-listed system includes a hood frame, quiet (40 decibels) adjustable speed blower, HEPA filter, and LED lighting. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Canopy Exhaust Hood

BioSafe® Universal Canopy Exhaust Hoods vent air away from the work area, and the operator, through a ceiling-mounted negative-pressure blower into the facility ducting system for additional scrubbing prior to outside release.

Vertical exhaust hoods are configured to protect the operator from exposure to hazards, toxins, or nuisance odors, but they do not protect the work area from contaminants. The stainless steel hood frame is free of cracks and crevices where microbes aggregate.

The turnkey systems include the hood frame, adjustable speed blower, and LED lighting. All system components are stocked and available for quick shipment.

BioSafe® Universal Benchtop Containment Exhaust Hood

BioSafe® Universal Benchtop Containment Exhaust Hoods vent air away from the work area, and the operator, through a ceiling-mounted negative-pressure blower and a filter stack before safely releasing the air back into the ambient environment. The two-stage filtration system is composed of a charcoal filter for fume vapor containment and a HEPA filter for particle containment. Rather than an open sash, this design includes a solid front panel, equipped with iris ports for work zone access, to ensure complete operator protection from hazards, toxins, or nuisance odors emanating from the work area. The stainless steel hood frame is free of cracks and crevices where microbes aggregate and colonize.

The turnkey UL-listed system includes a hood frame, whisper quiet (40 decibels) adjustable speed blower, HEPA filter, and LED lighting. All system components are stocked and available for quick shipment.

A - ISO Rating

(back to chart)

A1 - ISO 4

The maximum allowable concentration in an ISO class 4 environment is 10,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 4 cleanrooms, or enclosures, must maintain an average airflow velocity of 50 – 90 feet per minute and an average air change rate of 300 – 540 changes per hour.

A2 - ISO 5

The maximum allowable concentration in an ISO class 5 environment is 100,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 5 cleanrooms, or enclosures, must maintain an average airflow velocity of 40 – 80 feet per minute and an average air change rate of 240 – 480 changes per hour.

A3 - ISO 6

The maximum allowable concentration in an ISO class 6 environment is 1,000,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 6 cleanrooms, or enclosures, must maintain an average airflow velocity of 25 – 40 feet per minute and an average air change rate of 150 – 240 changes per hour.

A4 - ISO 7

The maximum allowable concentration in an ISO class 7 environment is 352,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 7 cleanrooms, or enclosures, must maintain an average airflow velocity of 10 – 15 feet per minute and an average air change rate of 60 – 90 changes per hour.

A5 - ISO 8

The maximum allowable concentration in an ISO class 8 environment is 3,520,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 8 cleanrooms, or enclosures, must maintain an average airflow velocity of 1 – 8 feet per minute and an average air change rate of 5 – 48 changes per hour.

B - Air Flow Direction

(back to chart)

B1 - Vertical Laminar Flow

Vertical laminar flow hoods include a filter fan unit, installed above the work zone, to draw ambient room air from above the hood, through a HEPA filter, and across the work area toward the front exit sash. The airflow pattern of a vertical laminar flow hood mirrors that of a laminar flow cleanroom with ceiling-installed HEPA filtered fan units. Vertical laminar flow hoods, or VLFs, protect items in the work zone - whether samples or instruments – from contamination, but do not protect operators from exposure to hazards, toxins, or odors. Vertical flow hoods provide several advantages over horizontal flow hoods: their space-saving design fits on crowded benchtops, the HEPA filters are easily accessible for certification or change-outs, and bulky instruments don’t impede airflow in the critical zones.

B2 - Horizontal Laminar Flow

Horizontal laminar flow hoods include a HEPA-filtered fan unit, installed in the rear of the work zone, to draw ambient air from behind the hood laterally across the work area toward the front exit sash. Horizontal flow hoods require additional depth beyond the unit footprint to accommodate the rear-mounted blower and make-up air space to feed the fan unit.

Horizontal flow hoods offer several advantages over vertical hoods: their shorter vertical clearance fits in spaces with low ceilings, equipment installed above the work zone, such as IV bars or overhead stirrers, does not impact laminarity, and the system protects against operator-borne cross-contamination (as workers sit downstream of equipment and samples).

B3 - Recirculating Laminar Flow

Recirculating vertical laminar flow hoods include a back plenum, with adjustable baffles, to divert air from the work zone through a vertical channel toward the ceiling-mounted fan unit, which directs air through a HEPA filter back into the work area. As recirculating flow hoods achieve a closed-loop system, the filter life span is significantly longer than standard single-pass flow hood designs.

B4 - Vertical Exhaust

Vertical exhaust hoods vent air away from the work area, and the operator, through a ceiling-mounted negative-pressure blower and through a set of filters before safely releasing the air back into the ambient environment. Exhaust hoods commonly use a two-stage filtration system composed of a charcoal filter for fume vapor containment and a HEPA filter for particle containment. Certain exhaust hoods include a duct collar to connect the integral blower to the facility’s air ventilation system, which may divert the air through a fume scrubber or additional filtration prior to outside release. Vertical exhaust hoods are designed to protect the operator from exposure to hazards, toxins, or nuisance odors, but do not protect the work area from contaminants.

C - Frame Material

(back to chart)

C1 - 304-Grade Stainless Steel

Rigid, durable 304-grade stainless steel resists most chemicals and biocides, accommodates changing environmental conditions (such as fluctuations in temperature and humidity), promotes easy disinfection, will not off-gas, and resist biofilm build-up.

D - Frame Design

(back to chart)

D1 - BioSafe Solid-Body Stainless Steel Frame

Terra’s BioSafe one-piece, solid-body, stainless steel frame is designed for aseptic applications requiring frequent disinfection. The frame is free of cracks and crevices where particles and germs collect. The solid-wall steel frame offers work zone privacy for confidential research or processing of controlled substances.

D2 - Viewing Panels

Terra’s standard stainless steel frame includes an interchangeable back panel, side panels and front sash for maximum versatility. The removable panels improve work zone visibility and simplify equipment access for planned maintenance. The panels, lined with a foam gasket, slide easily into the hood frame for a tight seal (free of fasteners or screws).

E - Viewing Panel Material

(back to chart)

E1 - Amber Acrylic

Economical amber acrylic is lightweight, impact-resistant, and absorbs UV and ambient blue light. Over time, acrylic is degraded by most cleaning agents, biocides, and solvents.

E2 - Black Acrylic

Economical, opaque black acrylic blocks ambient light for photo-sensitive applications or improved privacy. Although its high tensile strength provides for high impact resistance, acrylic is degraded by most alcohol-based cleaners and disinfectants.

E3 - Clear Acrylic

Cost-effective, clear acrylic is lightweight, impact-resistant, and provides high visual clarity. However, acrylic is prone to damage from exposure to acids, solvents, cleaning agents, and biocides.

E4 - White Acrylic

Economical, translucent, white acrylic diffuses ambient light and provides worker privacy. However, acrylic is damaged by frequent contact with many common cleaning agents.

E5 - Polycarbonate

Transparent polycarbonate resists temperatures up to 130 degrees Celsius and is compatible with common cleaning agents, such as Isopropyl Alcohol and Spor-Klenz.

E6 - Polypropylene, FM-Rated

Opaque, white polypropylene blocks ambient light to protect sensitive materials, resists acids, bases and solvents, and meets the FM 4910 flame retardant standards.

E7 - Non-Dissipative PVC

Transparent PVC includes a slight blue tint to partially absorb ambient light and resists most common cleaning agents and biocides. This material does not dissipate static charges and is not recommended for use in ESD-sensitive applications.

E8 - Static-Dissipative PVC

Transparent static-dissipative PVC protects against particle aggregation and safely conducts surface charges to ground. This formulation of PVC is recommended for ESD-sensitive applications as static charges cannot accumulate on the material surface.

E9 - Tempered Glass

Transparent tempered glass combines high impact resistance, broad chemical resistance, and high visual clarity.

F - Front Shield

(back to chart)

F1 - Tilt-Up Sash

The standard tilt-up sash enhances laminar airflow and prevents air from blowing directly at the operator’s face. The sash is composed of static-dissipative PVC, which resists chemicals and eliminates particle attraction from static charges.

F2 - Solid Panel with Iris Ports

For containment applications requiring a solid partition between the operator and work zone, Terra’s Universal hood is compatible with a PVC front panel equipped with iris ports for work area access.

I - Voltage

(back to chart)

I1 - 120 Volt

120-volt connections are suitable for standard laboratory power outlets in the United States.

I2 - 240 Volt

240-volt connections, common in Mainland Europe, require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

J - Standard Features

(back to chart)

J1 - Interchangeable Side Panels

Flow hoods with removable side panels increase the hood’s versatility by improving visibility plus simplifying equipment access. The side panels are lined with a foam gasket and slide into the hood’s frame for a simple and effective seal. All side panels are in-stock and ready for immediate shipment.

J2 - Energy-Efficient FFUs

Smart, energy-efficient filter fan units include brushless EC motors for quiet operation and infinitely variable speed control. The units produce low-heat and low-noise (down to 40 decibels) along with a maximum airflow of 1,117 CFM for high air change rate applications.

J3 - Room-Side Replaceable Filters

Room-side-replaceable filter fan units feature a gel-sealed filter and easy-open clips to allow for fast and efficient filter replacement without shutting down the hood.

J4 - Explosion-Proof Design

Explosion-Proof Laminar Flow Hoods are designed for working in areas where there is a risk of ignition due to flammable fumes or explosive dust. All electrical components (fan motor, LED lights, wiring) are rated compliant for Class I, Division 1, Groups C & D and Class II, Division 1, Groups F & G for hazardous locations.

J5 - Germicidal UV Lamp

Terra’s germicidal UV lamp, installed on the hood’s front panel, emits ultraviolet light to inhibit microbial growth on the work surface. The UV lamp is connected to a motion sensor to protect against operator exposure.

J6 - LED Lighting

Terra’s universal hoods include recessed, durable, and long-lasting LED lighting to illuminate the work area. The LED strip is positioned behind the front shield to prevent direct exposure to the operator's eyes.

K - Upgraded Features

(back to chart)

K1 - Room-Side Replaceable Filters

Room-side-replaceable filter fan units feature a gel-sealed filter and easy-open clips to allow for fast and efficient filter replacement without powering down the hood.

K2 - Ionizing System

Terra’s fan filter ionizers emit equal quantities of positive and negative ions to neutralize static charges within the work area. The system, designed for ESD-sensitive applications, requires no calibration or adjustments.

K3 - Power Strip

Terra’s UL-listed, rugged power strip includes 4 outlets to power process equipment, such as hot plates, shakers, overhead stirrers, or dry baths.

K4 - Adjustable Stand

Terra’s two-piece stand creates a vibration-isolated work surface underneath a benchtop hood, ideal for use with microscopes or other vibration-sensitive equipment. The outside stand supports only the hood to isolate vibration from the blower unit. The inside workbench nests within the outer stand without touching it, thus minimizing transmission of vibration from the hood to the work surface.

K5 - Base Cabinets

Base cabinet work benches include stainless steel or epoxy work surfaces and easily accessible storage space underneath the hood’s work area. The cabinets are equipped with magnetic locks to keep doors firmly shut.

K6 - Air Velocity Meter

AirGard air velocity meter continuously measures hood face velocity and sounds an audible/visual alarm when the airspeed drops below 90 feet per minute.

K7 - Cord Feed Through

Vacu-Pass systems provide an air-tight, sealed feed-through for power cords or cables. Installed on the hood’s side panel, the Vacu-Pass system is optimal for connecting process equipment inside the hood to external power sources.

K8 - ULPA Filters

ULPA (Ultra-Low Penetration Air) filters are rated as 99.999% efficient at removing particles ≥ 0.12 microns.

K9 - Customized Dimensions

For applications requiring customized dimensions, such as high-clearance hoods to house tall process equipment, like overhead stirrers or mixers, or models with additional depth to enclose liquid handlers, Terra’s in-house product engineering team is available to customize a system to your exact specifications. Though UL-listed, stocked components are integrated into customized systems, extended build times are necessary for dimensional adjustments.

K10 - HEPA-Filtered Duct Connection

For exhaust applications requiring connection to an in-house ducted ventilation system, the Universal Exhaust Hoods are compatible with Terra’s HEPA-filtered flow diffuser. The economical filter module includes internal baffling and a diffuser panel to ensure uniform airflow and a 12” diameter collar for connection to an external air supply.

Need Assistance with Product Configuration or Purchasing?

Visit Terra Universal Online for thousands of configurable cleanroom enclosures, equipment, and furnishings, many with in-stock and ready-to-ship availability. For nearly 40 years, Terra Universal has served the life science, pharmaceutical, biotechnology, and medical device markets.

Browse a wide selection of cleanroom filtration products and solutions including cleanroom enclosures, laminar flow hoods, fan filter units, glove boxes, and pass-through chambers.

Contact a Terra Sales Specialist via phone, live chat, or email for help with configuration, large purchases, and application expertise.

Terra Sales and Customer Service

Mon - Fri, 09:00 AM - 08:00 PM PST

Tel: +1 (714) 578-6100

Email: info@TerraUniversal.com