- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Special Application Cleanrooms

-

BioSafe® Modular Hybrid CleanroomsGroup of 4 products6606-PP-02FromAs low as $9,932Some ship in 20 - 30 daysULus Logo

BioSafe classic logo

BioSafe classic logo ISO 5 Icon

ISO 5 Icon 3 Width3 Depth1 Height1 ISO ClassWidth: 8', 10', 12'Depth: 8', 10', 12'Height: 8'ISO Class: ISO 5

3 Width3 Depth1 Height1 ISO ClassWidth: 8', 10', 12'Depth: 8', 10', 12'Height: 8'ISO Class: ISO 5 -

Custom Fire-Retardant Hardwall Cleanroom; 304 Stainless Steel Panels (6600-09)Request QuoteUsually ships in 20 - 26 daysULus Logo

WhisperFlow

WhisperFlow ISO 5 Icon

ISO 5 Icon

-

Custom Fire-Retardant Hardwall Cleanroom; Powder-Coated Steel Panels (6600-04)Request QuoteUsually ships in 20 - 26 daysULus Logo

WhisperFlow

WhisperFlow ISO 5 Icon

ISO 5 Icon

Features and Benefits

Print

Copy Copied

Affordable customization to unique requirements!

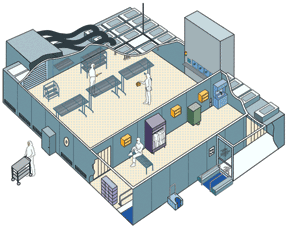

- Terra's modular designs allow versatile configurations using standard components, whether you need a small equipment enclosure or a multi-suite processing facility

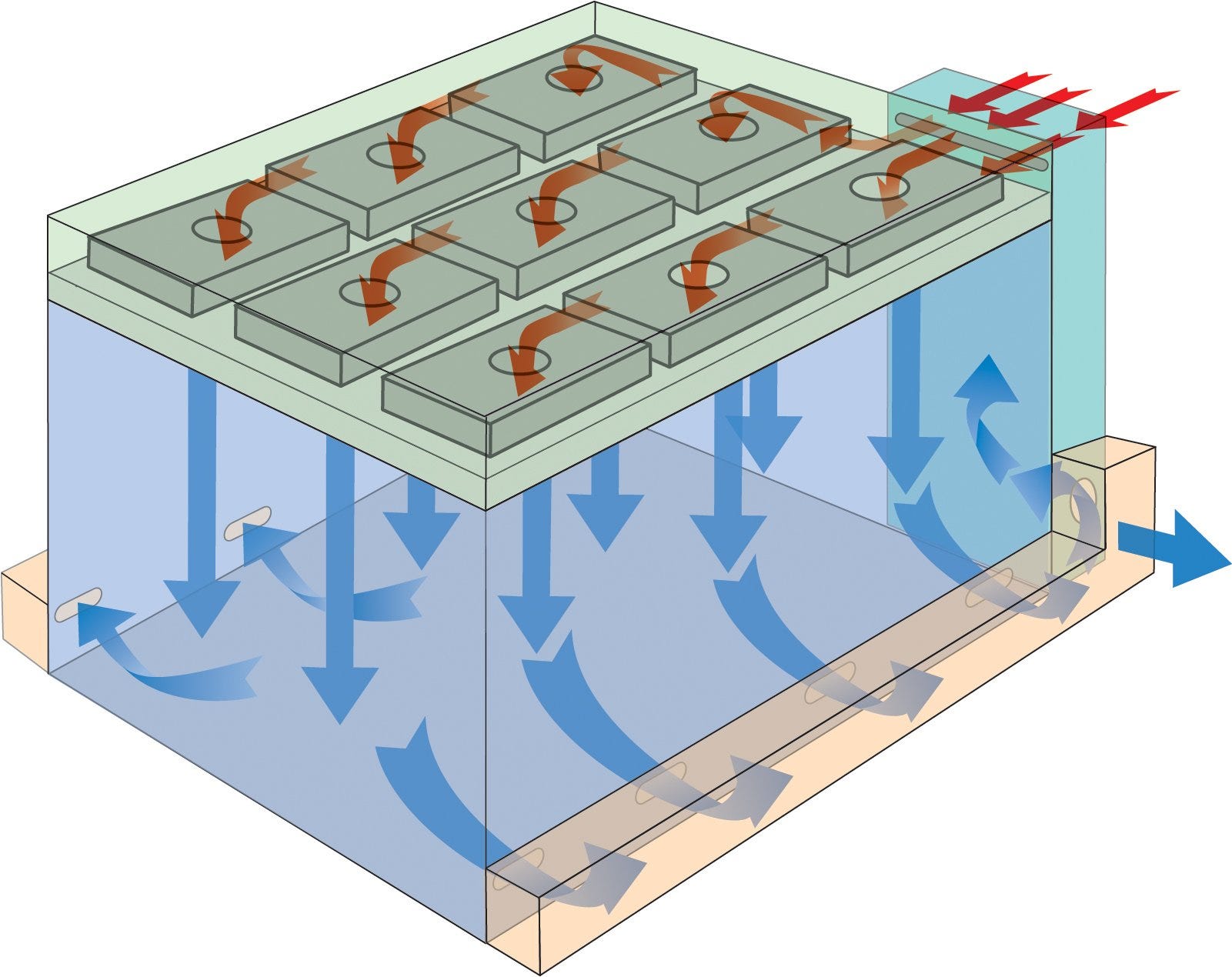

- Versatile plug-and-play Power Distribution Modules allow addition of ceiling fan/filter units and lights to meet any cleanliness requirement or to upgrade ISO levels or lighting levels after installation

- Modular frame and panel designs, in several application-specific materials, adapt to any floor plan requirement

- Automated fan controls simplify pressure balancing, Building Management System (BMS) integration, and certification of large, multi-suite facilities

- Stand-alone A/C modules or integration with existing air handling system

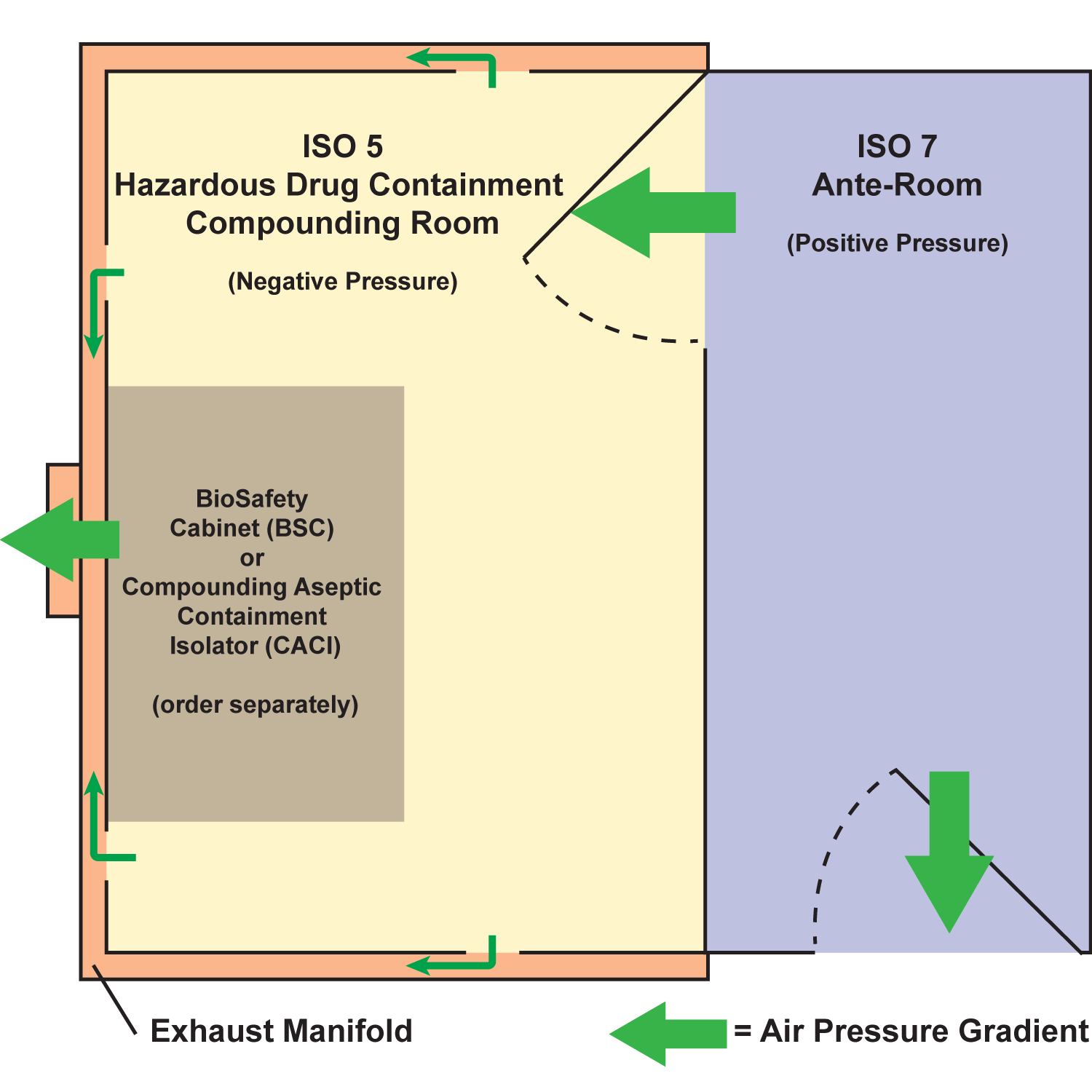

- Consultation services available to meet industry-specific regulations, such as USP 797/800 compounding requirements

- Terra’s full engineering services adapt designs to accommodate unique equipment or facility integration challenges

Call or submit a QuickQuote Form for assistance with a modular cleanroom tailor-made to your application!

Critical Environment Solutions

Terra's mission is to help customers in highly regulated industries transform the world with critical environment solutions that improve health, safety, performance, and yields. These environments may comply with stringent UL, ISO, IEST, ASTM and OSHA standards and local requirements.

Explosion-Proof Softwall Modular Cleanroom

Explosion-Proof Softwall Cleanrooms feature sealed conduit and junction boxes leading to the explosion-proof lights and FFUs, in compliance with NEC code for Class I, Division 1 environments

Portable Particle Containment Room

Containment Room isolates dirty operations inside a lab or cleanroom; reverse-flow HEPA fan/filter units contain dust to allow clean air release.

Explosion-Proof HEPA Fan and Filter Unit

Explosion-proof ULPA fan/filter unit features sealed or non-sparking components, including motor, all-potted conduit and grounded filter screens that meet NEC requirements for Class I, Division 1 hazardous locations.

Explosion-Proof Potted Fittings

Conduit is filled with an expanding cement mixture to isolate explosion-proof components from potential sources of ignition; explosion-proof fittings meet requirements of NEC for Class I, Division 1 hazardous locations.

Insulated Cleanrooms

Insulated Hardwall Cleanroom includes rigid foam insulation sealed between dual polypropylene panels to provide better temperature stability in temperature-controlled operations.

Custom Work is Standard!

Modular designs allow versatile configurations tailored to your requirements. Terra's design and fabrication capabilities accommodate unique facility challenges.

Special Application Cleanrooms

-

Custom Low Humidity Controlled Dry Rooms by Scientific Climate Systems

Custom Low Humidity Controlled Dry Rooms by Scientific Climate Systems

-

Custom Walk-In Burn-In Chamber by Scientific Climate Systems

Custom Walk-In Burn-In Chamber by Scientific Climate Systems

-

Equipment Enclosure for Conveyor Line

Equipment Enclosure for Conveyor Line

-

Explosion-Proof Softwall Modular Cleanroom

Explosion-Proof Softwall Modular Cleanroom

-

Watch Terra's Portable HEPA Filtration System Video

Watch Terra's Portable HEPA Filtration System Video

-

Insulated ISO-Rated Hardwall Modular Cleanroom

Insulated ISO-Rated Hardwall Modular Cleanroom

-

Explosion-Proof Softwall Cleanroom

Explosion-Proof Softwall Cleanroom

-

Modular Production Control Room

Modular Production Control Room

-

Modular Warehouse Office

Modular Warehouse Office

-

Watch Terra's Video on Pharmaceutical Air Lock Designs

Watch Terra's Video on Pharmaceutical Air Lock Designs

-

Insulated Hardwall Cleanroom

Insulated Hardwall Cleanroom

-

Mezzanine Cleanroom

Mezzanine Cleanroom

-

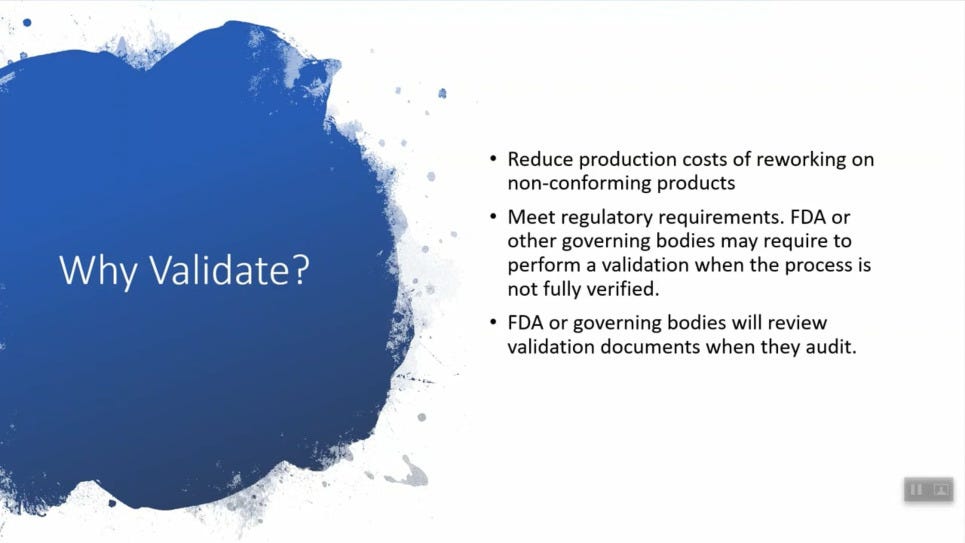

Terra Universal IQ-OQ Process

Terra Universal IQ-OQ Process

Technical Resources

Print

Copy Copied

Modular Cleanrooms Client List

Terra's extensive customer list indicates widespread acceptance of the modular cleanroom concept across in many industries.

In the dozens of applications these projects represent, modular cleanrooms provided an ISO 4-8 processing environment in a fraction of the time, at a fraction of the cost, associated with conventional brick-and-mortar facilities.

Aerospace/Defense

- Boeing

- Bilkent University Nanotechnology Research Center

- Brookhaven National Laboratory

- Cal Tech

- DFAS - Rock Island Operating Location

- Goodrich Aerostructures

- Hyatt Die Cast And Engineering

- Jacobs Technology, Inc.

- JPL (Jet Propulsion Labs)

- Lawrence Livermore National Security, LLC

- Lockheed Martin

- Massachusetts Institute of Technolo

- Noblis, Inc.

- Phoenix International, Inc.

- Raytheon

- Reynolds Systems Inc

- Sandia National Labs

- SETI Institute

- Teledyne Energy Sytems

- UCAR

- USDA - NCAUR - ARS

- UT- Battelle, Inc.

Animal/Veterinary Sciences

- Epitopix, LLC

- Vet Rx

Biotech/Biomedical/Genomics

- 454 Life Sciences

- Avant Immunotherapeutics

- Bioheart Inc.

- Biomedical Research Institute of NM

- Biotech Manufacturing Center of Texas

- Cambrex Bioscience, Hopkinton, Inc.

- Creo Products

- Delsite Biotechnologies Inc.

- Digitex International USA, Inc.

- Dryocon Bioconcepts, Inc

- Epeius Biotechnologies

- Fermilab

- Genvault

- Hematech Inc.

- ID Biomedical Corporation

- ILC Dover, Inc.

- International Biologics

- Irvine Scientific

- JSC Intech Vaccum

- Medtronix Xomed

- PML Microbiologicals

- PrimeGen Biotech LLC

- Pro Vitro, LTD.

- Proliant Inc.

- Saic-Frederick

- Sterilator

- Steris Corporation

- Ultradent

- University of Kentucky

- Xcellerex

Chemicals

- Advanced Automation

- Air Products and Chemicals, Inc.

- California State University Los Angeles

- DuPont de Nemours & Co.

- Gaylord Chemical Corporation

- Labchem, Inc.

- North Carolina State University

- PPG Industries, Inc.

- Total Rohm and Haas Company

- SouthWest NanoTechnology

- Total Pertrochemicals USA, Inc.

- University of Texas at Austin

- XBiotech USA Inc

Construction/Builder/Architect

- Antisel Selidis Bros S.A.

- Brycon Corporation

- Caribbean Eng. Tech. Inc.

- Consigli Construction Co., Inc.

- Davko Services, LLC.

- Demar, LTD.

- Division 5-15 Inc.

- Green Tweed Co.

- Gulfcoast Constulting Group

- Jacobs Engineering

- M + W Zander

- McCarthy Construction

- MD Building Products

- Pro One LLC

- Techniserv S.A.

- Tucker Mechanical

- Woodruff Design & Construction

Electronics/Instruments/Auto

- Allied Motion Computer Optical Products

- Battelle Pacific NW Division National Labs

- Bay Advanced Technologies, LLC

- Brillian Corporation

- Calvary Automation

- Canberra

- Cellasic Corp.

- CKS Solution Inc.

- Daniels Electronics

- Delta Video Technology Ltd.

- Eddy Co.

- Electronica Clarion S.A. de C.V

- Finesse Solutions

- Hitachi Via Mechanics USA, Inc.

- Kaai Inc.

- KIK Custom Products

- NanoNexus

- NWL Capacitors

- Riedon Inc.

- Soraa Inc.

- Specialty Machine

- Strategic Polymer Sciences

- Tape Innovations LLC

- TIR Systems Ltd.

- University of Cyprus

- Valutech Out Sourcing LLC.

- Verity Instruments

- VLSI Standards

- Virginia Export Group

- VTI Technologies

- ZAP Lasers

Medical Device/Implants

- ABC Medical Device

- Acadiana Plastics, Inc.

- Accellent

- ACS (Guidant)

- Adept-Med International, Inc

- Allograft Innovations

- Anazao Health Corp.

- Apec

- AxioMed Spine Corporation

- Bacterin Inc./Global Vantage

- Bone Bank Allografts

- Claros Diagnostics

- Correx Inc.

- CS Medical Werks, Inc.

- Datex Ohmeda

- EDKA Research

- Ethicon

- Fziomed Inc.

- Hamot Medical Center

- Hansen Medical

- HNS International, Inc.

- Impact Projects

- Intelligent Medical Innovations

- Intra-Lock International

- Introgen Therapeutics

- LifeNet Health

- Medwaves Inc.

- Meridian Bioscience

- OsteoBiologics, Inc.

- Pari Inoovative Manufacturers, Inc.

- Parkview Healthy Systems

- Terumo Medical Corp.

- The Polymer Tech Group

- The Roho Group

- Tenacore Holdings

Medical/Hospital

- Long Beach Memorial Medical Center

- Memorial Medical Center

- St. Luke's Episcopal Hospital

- Tyco Healthcare - Augusta

Optics/Lasers/Photonics

- 4D Technology

- ABSee Laser

- Alsius

- Aselsan Inc.

- ASML US, Inc

- CDM -Optics, Inc.

- General Optics

- JDSU

- JP Sercel Assciates Inc

- Kodak Graphic Communications

- L3 Communications SSG - Tinsley

- Laserscope

- LightSmyth Technologies

- Lund Institute of Technology

- MP Amber Fund

- Newport Corp

- O&S Research, Inc.

- Optikos Corp

- Research Electro-Optics, Inc.

- Selectron Industrial Company

- Space Photonics

- Spectra Physics Lasers, Inc.

- Suntron Corporation

- University of Texas at Dallas

- UT-Battelle LLC

Other

- Albany International

- Avery Dennison

- Balboa Capital Corporation

- CID-Research & Development Center

- Cnri

- Critical Disposables

- Five Star Technologies

- Flavours Inc.

- Fluidigm Corp

- Hydrogen Solar LLC

- Infrared Solutions, Inc

- KP Pharmaceutical Tech

- Martek Biosciences

- NanoMaterials Discovery Corp.

- National City Commercial Capital Corp.

- Norman Wright

- North Carolina A & T State Univ.

- Osmic, Inc.

- R&D Tool and Engineering

- Southern University

- Sverdrup Technology

- Teck Cominco Metals Ltd.

- The Aerospace Corporation

- Tristar Capital, LLC

Pharmaceuticals

- Abraxis Bioscience, LLC

- Acceleration Inc.

- Actavis

- Appalachian Infusion

- AVI Biopharma

- AzoPharma

- Baxter Healthcare Corp.

- Bayer Healthcare LLC

- BET Pharm LLC

- Biogen Idec Inc

- CCI

- Celator Pharmaceuticals Corp.

- Cephalon Incorporated

- Dey, L.P.

- Equinox Healthcare, Inc.

- GlaxoSmithKline

- Hospira

- Lifehouse

- Macco Organiques Inc.

- Merck Sharp & Dohme Quimica de PR

- Molecular Devices

- MOVA Pharmaceutical Corporation

- Nanotherapeutics

- Pharmaceutics International

- Pharmavite

- Reckitt Benckiser Inc.

- Selmedica

- Serologicals Corp.

- Southwest Anti Aging Clinic

- Total Sonotech Inc

- United Therapeutics

- Vital Pharma Inc

- VNAIS-Anaheim

- W L Gore & Associates

- Watson Labs

Rep/Distributor/Reseller/Dealer

- Andwin Scientific

- Fisher Scientific (Thermo Fisher)

- Geo-Centers Inc

- Guardline Technology Ltd.

- Haily Technology Equipment Co. Ltd.

- Harris Environmental Systems

- Kassir Co.

- MW Zander

- National Laboratory Specialists

- NexLab Design, Inc.

- Romex B.V.

- SPEC Process Eng. & Const. Inc.

- VWR International

- Water & Process Technologies, Inc.

Semicon/MicroElect/SMT/Comptrs

- Altaix Electronica S.A

- Applied Aerospace Corporation

- Belford Research, Inc.

- Bench2Bench

- Boston Scientific/Guidant (IRE) Ltd.

- Cisco Systems

- Clean Sciences Technology

- Corning Inc.

- Creative Technology Systems, LLC

- Critical Data Ltd.

- CSIRO

- Cypress Semiconductors

- Dalhousie University

- E&S Technologies

- ETS

- EUV Technologies

- FLIR Systems Inc., Indigo Operations

- Fluor Daniel Caribbean, Inc.

- Fujitsu Labs Of America Inc

- Hamilton College

- IFW Dresden

- Insulator Seal

- Intevac, Inc.

- Jeffrey Weiss

- KLA-Tencor

- Kopin Corporation

- Kulite Semiconductor Products, Inc.

- Laser Light Technologies, Inc.

- Louisiana State University

- MXF Technologies, Inc.

- Nanophase Technologies Corporation

- NanoSperse LLC

- NIST

- North Carolina A & T State Univ.

- Nova Sensors

- Paramit Corporation

- Philips Ultrasound, Inc.

- Planar Semiconductor Inc.

- Sani-Tech West

- Seaware Technologies

- Seltech Electronics

- Smart Modular Technologies

- Stevens Institute Of Technology

- Synetics Solutions

- Trumpf

- Ultraclean Technology

- Universidad Nacional de General San Martin

- University of Texas at Arlington

- University of Utah

- US Dynamics

- Varian Semiconductor Equip.Associates

- VetcoGray Controls Inc.

- Z Microsystems, Inc.

TUI Competitor

- Poly-Flow Engineering, LLC

- Western Environmental

University and Government Laboratories

- Brookhaven National Laboratory

- California Institute of Technology (Cal Tech)

- California State University, Los Angeles

- Dalhoisie University

- Hamilton College

- Louisiana State University

- Lund Institute of Technology

- North Carolina State University

- Penn State College Of Medicine

- UCLA, Engineering IV

- University Of Arizona Steward Observatory

- University of Arkansas

- University of California Berkeley

- University of California Santa Barbara

- University Of California Santa Cruz

- University of Cyrus

- University Of Georgia

- University Of Hawaii At Manoa

- University of Illinois at Chicago

- University of Texas at Arlington

- University of Texas at Austin

- University of Texas at Dallas

- University of Utah

- University of Victoria

video

Glass Cleanroom Wash-Down Video

This video demonstrates benefits of a BioSafe cleanroom and the easy-clean feature of a tempered glass, including suitability for wash-down disinfection.

.jpg)