- Available ISO Ratings: ISO 6, ISO 7, ISO 8

- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Here at Terra Universal, we’ve made it our mission to offer the best possible lead times in the industry. In addition to aggressive stocking programs and streamlined fulfillment, Terra Universal also offers several services that ensure you receive your products as quickly as possible.

Terra's QuickBuild Program includes dozens of products with stocked components ready for quick assembly and shipment in 5 days.

Examples of QuickBuild-eligible products include:

Quick Build services are available for Terra products assembled with in-stock, on-hand components. Therefore, Terra can provide these items assembled and ready for shipment within 4 - 6 business days.

Mon - Fri, 09:00 AM - 08:00 PM PST

Tel: +1 (714) 578-6100

Email: [email protected]

• Marks & Listings: UL, ULC

Watch Terra's BioSafe® Universal Benchtop Hoods Video

Watch Terra's BioSafe® Universal Benchtop Hoods Video

Watch Terra's Vibration Isolation Stand Video

Watch Terra's Vibration Isolation Stand Video

Vibration Isolation Stand

Vibration Isolation Stand

Watch Terra's ErgoHeight™ Workstations Video

Watch Terra's ErgoHeight™ Workstations Video

Terra Universal WhisperFlow Laminar Flow Hoods

Terra Universal WhisperFlow Laminar Flow Hoods

Laminar Flow Hood Smoke Test

Laminar Flow Hood Smoke Test

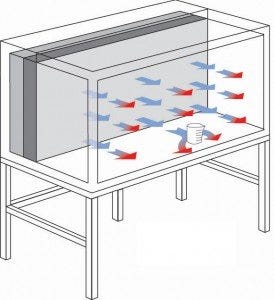

Laminar is derived from the Latin lamina, a thin sheet of material. When used to describe a laboratory hood, the term "laminar flow" refers to air exiting a filter in parallel layers that move at the same speed and in the same direction, vertically or horizontally across the enclosure. Any particles introduced in a laminar flow of air during a work process are predictably swept in the direction of the flow and removed from the enclosure, downstream of critical processes.

Disruption to laminarity results in turbulence, a randomized flow that suspends particles in eddies rather than removing them. Because they can remain in the system, carried by “second-pass” air that swirls around the critical work area, contaminants are deposited unpredictably, often with disastrous results.

Vertical laminar flow (VLF) hoods position the fan filter unit on top of the hood, a space-efficient design that accommodates most facilities as long as overhead clearance isn’t a problem. Horizontal laminar flow (HLF) hoods position the fan on the back of the hood, necessitating as much as 18” or more additional floor or bench space for fan, filter and make-up air flow. In a cleanroom or lab where space is at a premium, that difference alone could determine your choice. Footprint Advantage: VLF Hood

VLF hoods often have an adjustable sash at the front of the hood to maintain the downward laminar air flow. HLF hoods are generally open at the front of the hood to ensure unrestricted horizontal air flow. The larger opening of an HLF hood makes placement of large objects and instruments easier when compared to a VLF hood although, without a sash to serve as a shield, chemical fumes or powders inside the work area may blow into the operator's face. Sash Advantage: VLF Hood (operator safety); HLF Hood (transferring large materials)

Although both hoods are effective at sweeping particles from the hood, air eventually encounters obstacles that disrupt laminar flow. In most VLF hoods, the work surface creates turbulence, so critical processes must be performed above the surface to avoid contact with “second-pass” air that could contaminate a sensitive operation. Some VLF designs include a perforated floor with sub-surface plenum to reduce this obstruction, but these measures add cost. HLF hoods generally minimize this airflow disruption. However, large objects placed on the work surface can cause swirling or contaminate downstream materials, so critical operations should take place adjacent to the filter face. Laminar Flow Advantage: HLF Hood

We end with a tie; your working conditions will help you determine which of these advantages matter most in your operation.

Safety Alert: Under no circumstances should laminar flow hoods be used in the presence of hazardous materials. Use a fume hood or biological safety cabinet for safe biohazard containment.

| Model | Horizontal Laminar Flow (HLF) Station | Vertical Laminar Flow (VLF) Station | ValuLine™ VLF Station | ValuLine Whisperflow Hood | Portable CleanBooth |

|---|---|---|---|---|---|

| Flow | Horizontal | Vertical | Vertical | Vertical | Vertical |

| Nominal Widths | 7', 6', 4' (2.1 m, 1.8 m, 1.2 m) | 8', 6', 5', 4' (2.4 m, 1.8 m, 1.5 m, 1.2 m) | 8', 6', 5', 4' (2.4 m, 1.8 m, 1.5 m, 1.2 m ) | 6', 5 ', 4', 3 ', 2 ' (1.8 m, 1.5 m, 1.2 m, .9 m, .6 m) | 6', 4' (1.8 m, 1.2 m) |

| Nominal Overall Depth and Height | 44"D x 63"H (1118 mm x 1600 mm) | 41"D x 90"H (1041 mm x 2286 mm) | 41"D x 90"H (1041 mm x 2286 mm) | 24”/30”D x 41”H (610/762 mm x 2286 mm) | 30"D x 82"H (762 mm x 2083 mm) |

| Nominal Working Space | 30"D x 28"H (762 mm x 711 mm) | 27"D (686 mm); height depends on workbench used | 27"D (686 mm); height depends on workbench used | 24”/30”D x 23”H (610/762 mm x 584 mm) | 24"D (610 mm); height depends on workbench used |

| Construction Material / Options | Powder Coated Steel Frame | ||||

| Work Surface Options | Workbench sold separately; many top materials available. 2-piece frame isolates fan vibration. | 304 Stainless Steel work surface included | Placed on user-furnished bench (stands available) | Workbench sold separately; many top materials available. 2-piece frame isolates fan vibration. | |

| Blower Type | Integrated Fan/Filter Unit | Integrated Fan/Filter Unit | Integrated Fan/Filter Unit | Integrated Fan/Filter Unit | Integrated Fan/Filter Unit |

| Air Flow, | 7' (2.1 m) 6' (1.8 m) 4' (1.2 m) | 8' (2.4 m) 6' (1.8 m) 5' (1.5 m) 4' (1.2 m) | 8' (2.4 m) 6' (1.8 m) 5' (1.5 m) 4' (1.2 m) | 6'(1.8 m) 5'(1.5 m) 4' (1.2 m) 3 ' (.9 m) | 6' (1.8 m) 4' (1.2 m) |

| CFM (m³/hr) | 1130 (1920) 960 (1632) 650 (1104) | 1300 (2209) 960 (1632) 840 (1427) 650 (1104) | 1300 (2209) 960 (1631) 840 (1427) 650 (1104) | 960 (1632) 840 (1427) 650 (1104) 558 (948) | 960 (1632) 650 (1104) |

| Filter Types | HEPA or ULPA | HEPA or ULPA | HEPA or ULPA | HEPA or ULPA | HEPA or ULPA |

| Prefilter | Washable Polyurethane Foam | Washable polyurethane Foam | Washable polyurethane Foam | Washable polyurethane Foam | Washable polyurethane Foam |

| Portability / Installation Access | Not portable | Not portable. Wider than standard door frame | Not portable. Wider than standard door frame | Portable | Portable: CleanBooth frame uses casters. |

| Front Sash Configuration Options | Take-up air slots and plenums on three sides of the work area | Tilt-Up | Uses softwall panel kits: vinyl, anti-static vinyl, or non-outgassing polyurethane | ||

| Lighting | LED | LED | LED | LED | Optional fluorescent lighting |

| Noise Level, Measured 30" (762mm) from filter face at 90 FPM (.46m/s) | <50 dBA | <50 dBA | <50 dBA | <50 dBA | <50 dBA |

| Airflow Monitor Options | Minihelic gauge monitors backpressure across filter | Includes touch screen controls with backpressure indicator | Optional: air velocity meter and differential pressure gauge for filter backpressure | Optional swing-vane anemometer | Optional: air velocity meter and differential pressure gauge for filter backpressure |

| Power Requirements | 120 VAC, 50/60 Hz or 220VAC, 50 Hz | 110 VAC, 50/60 Hz or 220VAC, 50 Hz | 110 VAC, 50/60 Hz or 220VAC, 50 Hz | 110 VAC, 50/60 Hz or 220VAC, 50 Hz | 120 VAC, 50/60 Hz or 220VAC, 50 Hz |

| Price Range | $9,300 – $14,300+ | $6,000 - $14,000+ | $5,000 - $10,000+ | $1500 | $2,000 - $4,500+ |

| Application Synopsis |

On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.