- Available ISO Ratings: ISO 5, ISO 6, ISO 7, ISO 8

• Frame Material: Powder-Coated Steel

• Overall Dimensions: Custom

• Panel Material: Polypropylene

• Application: Horizontal Flow

• Unit of Measure: EA

• Frame Material: Powder-Coated Steel

• Overall Dimensions: Custom

• Panel Material: Polypropylene

• Application: Horizontal Flow

• Unit of Measure: EA

Want it faster ? Read about FasTrak

• Frame Material: Powder-Coated Steel

• Overall Dimensions: Custom

• Panel Material: Polypropylene

• Application: Horizontal Flow

• Unit of Measure: EA

• Marks & Listings: UL, ULC

• Weight, Shipping: 2,203 lb

• Dimensions, Shipping: 153" W x 65" D x 46" H

• Package Type: Skid

Modular Cleanroom with A/C and RH Control

Modular Cleanroom with A/C and RH Control

Hardwall Modular Cleanroom

Hardwall Modular Cleanroom

Multi-Suite ISO-Rated Hardwall Modular Cleanroom

Multi-Suite ISO-Rated Hardwall Modular Cleanroom

Fire-Resistant Hardwall Cleanroom

Fire-Resistant Hardwall Cleanroom

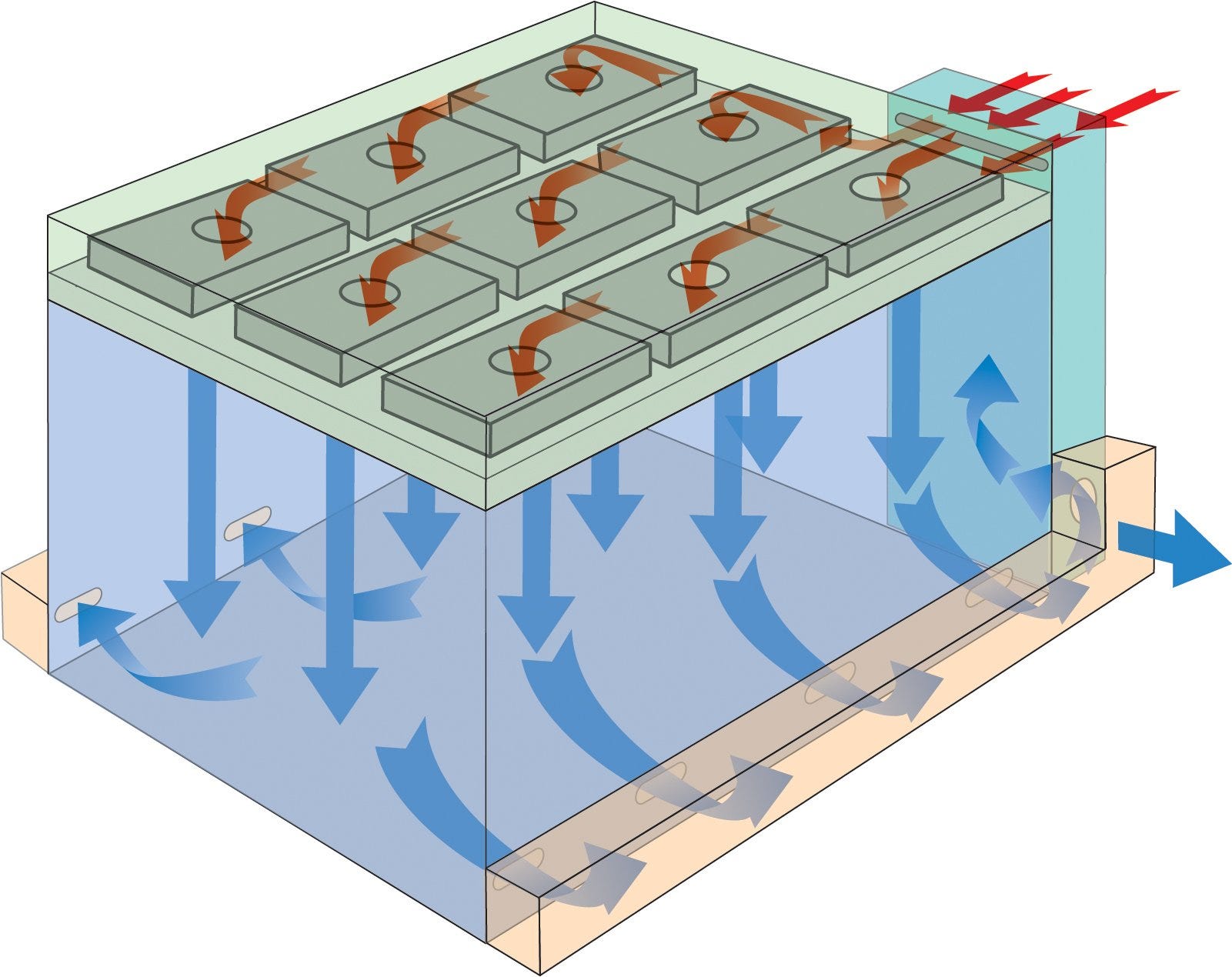

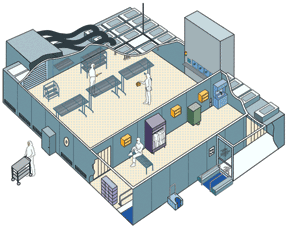

Hardwall modular cleanrooms provide a completely enclosed, rigid free-standing structure with vents to exhaust air. Terra Universal fabricates the framing from powder-coated or stainless steel; wall panels are available in clear acrylic, static-dissipative PVC, polycarbonate and tempered glass, as well as opaque white polypropylene.

Because they can be specified, built and installed in a fraction of the time associated with brick-and-mortar clean rooms, modular hardwall rooms are ideal for fast ramp-up projects or short production cycles that may not merit the expense and delay of a conventional room.

Hardwall clean rooms can maintain pressure differentials, which may be required to meet certain standards for cleanliness (ISO 5 or 6, as well as USP compounding regulations). Their wall panels are more durable and easier to clean than softwall panels or curtains.

Hardwall construction also allows temperature and humidity control, which is enhanced in a recirculating clean room design using vertical air returns in conjunction with A/C units. Unlike softwall designs, hardwall cleanrooms can provide negative-pressure containment.

A negative-pressure containment room must pull more air out than it introduces through ceiling fan/filter units. Air is typically exhausted through ductwork tied to a ventilation fan.

Ductwork most often runs along the bottom perimeter of the clean room and draws air from multiple locations along the room perimeter to minimize disruption to laminar flow. The ventilation fan mounts on the floor outside the cleanroom, or ductwork may pass exhaust upward to a roof-mounted fan. In order to maintain negative pressure, this fan must be capable of pulling about 30% more air than the HEPA filters introduce.

Depending on the application, a containment room may require exit filtration: either HEPA/ULPA filters for particles and aerosols, and/or carbon filters to remove chemical fumes.

Internal walls and careful positioning of ceiling Fan/Filter Units (FFU) allows you to configure a facility with many rooms, each operating at a different ISO cleanliness level. Some points to keep in mind:

Beside controlling particulate contamination and internal positive or negative pressure, hardwall cleanrooms are available to meet these special requirements:

On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.