Fan Filter Unit Frequently Asked Questions

What is a Fan Filter Unit and how is it used?

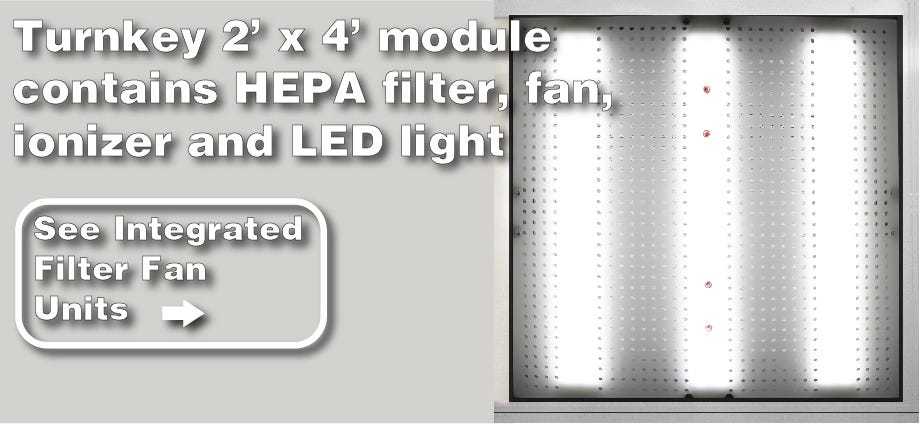

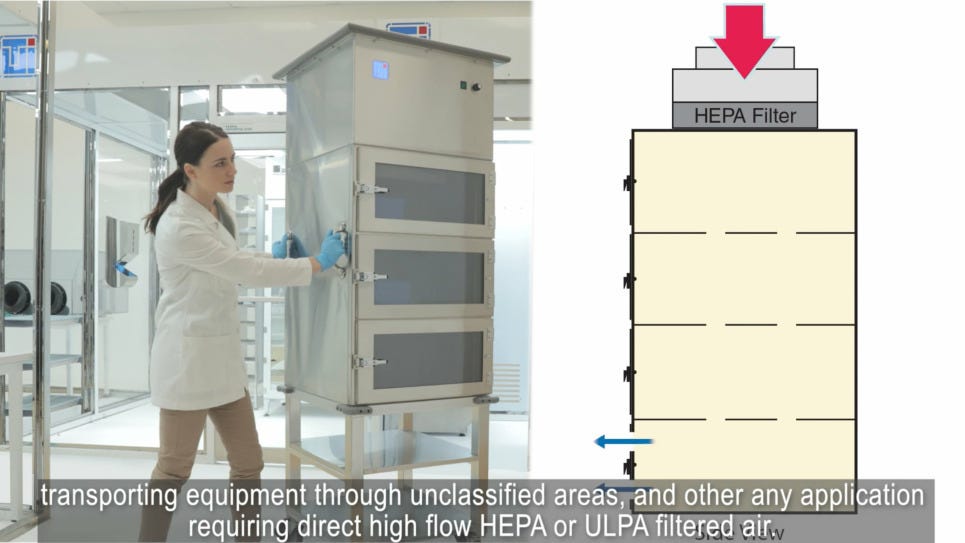

A fan filter unit (FFU) uses HEPA or ULPA filtration to protect products and personnel from unwanted particles and germs. The HEPA filter (or ULPA filter) in the FFU is constructed of delicate tightly woven fibers to catch sub-micron particles. FFUs are most commonly used in cleanrooms, however are also used with many different types of products such as laminar flow hoods, lab glove boxes, and storage cabinets

In a typical cleanroom, the fan powered hepa filter mounts on top of the ceiling grid and scrubs air clean as the motor pulls air from outside the cleanroom, pushes it through the HEPA filter and into the cleanroom.The downward top-to-bottom flow of air into the cleanroom provides laminar airflow - a single pass unidirectional flow of air- starting from the ceiling and exiting near the floor--to help flush out other contaminants that may be introduced inside the cleanroom. The clean filtered air being pushed into the cleanroom also creates a positive pressure environment to help keep unwanted contaminants from drifting inside the cleanroom.

How do you determine how many FFUs are needed for a cleanroom?

A critical factor in cleanroom design is controlling air-change per hour (ACH), also known as the air-change rate, or ACR. This refers to the number of times each hour that filtered outside air replaces the existing volume in a building or chamber.

To estimate the number of FFUs needed for your cleanroom HEPA filter system, you will need to know (1) the size of each room (L x W x H), and (2) the ISO classification for each room. Each ISO class has an acceptable range of air changes per hour (ACH). Once the required air change figure is established, the number of required FFUs can be approximated using this formula: No. of FFUs = (Air Changes/Hour ÷60) x (Cubic ft. in room÷ 650*).

*Note: This is the CFM output of the FFU. Keep in mind different types of motorized fan filter units and speed settings will have different flow rates, so this figure will need to be adjusted accordingly.

For example: Meeting Class 100 standards using the low-end air change recommendation (240/hour) inside a 12’ x 12’ x 7’ cleanroom, with 1008 cu. ft. of volume, requires 6 FFUs. To meet the same standard using the high-end air change recommendation (480/hour) requires 12 FFUs.

Terra’s report on ISO Cleanroom Standards provides an in-depth overview of cleanroom requirements for each cleanroom ISO classification. Alternatively, you can call, email, or chat with a live cleanroom specialist for a free consultation on your cleanroom needs.

What is the difference between an FFU with a PSC motor and an FFU with an EC motor?

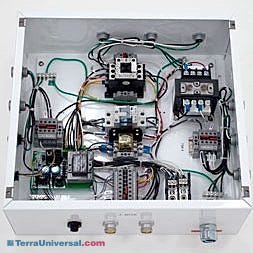

Permanent split capacitor (PSC) motors offer a simple solution for low-need operations, namely small-scale projects. They provide an overall low upfront purchase costs and ease of operation for most cleanroom environments. These motorized HEPA filter modules can be installed with a simple remote switch—no network programming required.

However, when considering longer endeavors, especially those with ever-changing circumstances, the electronically commutated (EC) motor will pay for itself with energy savings. Terra’s Smart® WhisperFlow® energy efficient FFU with EC motors demonstrate a 50% reduction in power consumption compared to the standard PSC units when running both units at 90 feet per minute face velocity.

These energy efficient FFUs demonstrate a service-life exceeding 90,000 hours, close to double that of PSC units. Terra’s smart motors reduce the risk of costly down-time due to an unexpected FFU failure. Additionally, with the reduction in energy costs, you can earn Leadership in Energy and Environmental Design (LEED) points for your cleanroom set-up, further driving down operational costs.

ECM FFU systems can also utilize an FFU control system and can be programmed to compensate for shifts in air pressure—something as simple as opening a cleanroom door can drastically change the working environment—increasing or decreasing fan movement speeds to align. The same energy-savings can be applied to low demand times as with situations that require even less energy-use than what’s available with PSC units—again, wattage would simply be wasted and resources consumed.

The breakdown below illustrates the savings:

FFU Power Consumption (watts)

| Motor Type | Low Speed | Medium Speed | High Speed |

|---|---|---|---|

| PSC motor | 365W | 380W | 430W |

| EC motor | 90W | 168W | 350W |

FFU Cost Saving Comparison

| FFU Type | Unit Cost | Annual Energy Cost | Lifetime Energy Cost | Lifetime Dollar Savings |

|---|---|---|---|---|

| Standard FFU (PSC motor) | $776 | $430 | $4,800 | 0 |

| Smart FFU (EC motor) | $1,089 | $127 | $1,414 | $3,386 |

| Values are based on the following parameters: Operating 24 hours a day, 7 days a week; medium speed for 8 hours and low speed for 16 hours, 5 out of 7 days; low speed for 24 hours, 2 out of 7 days; energy cost at $0.14/kWh; operating life at 90,000 hours. | ||||

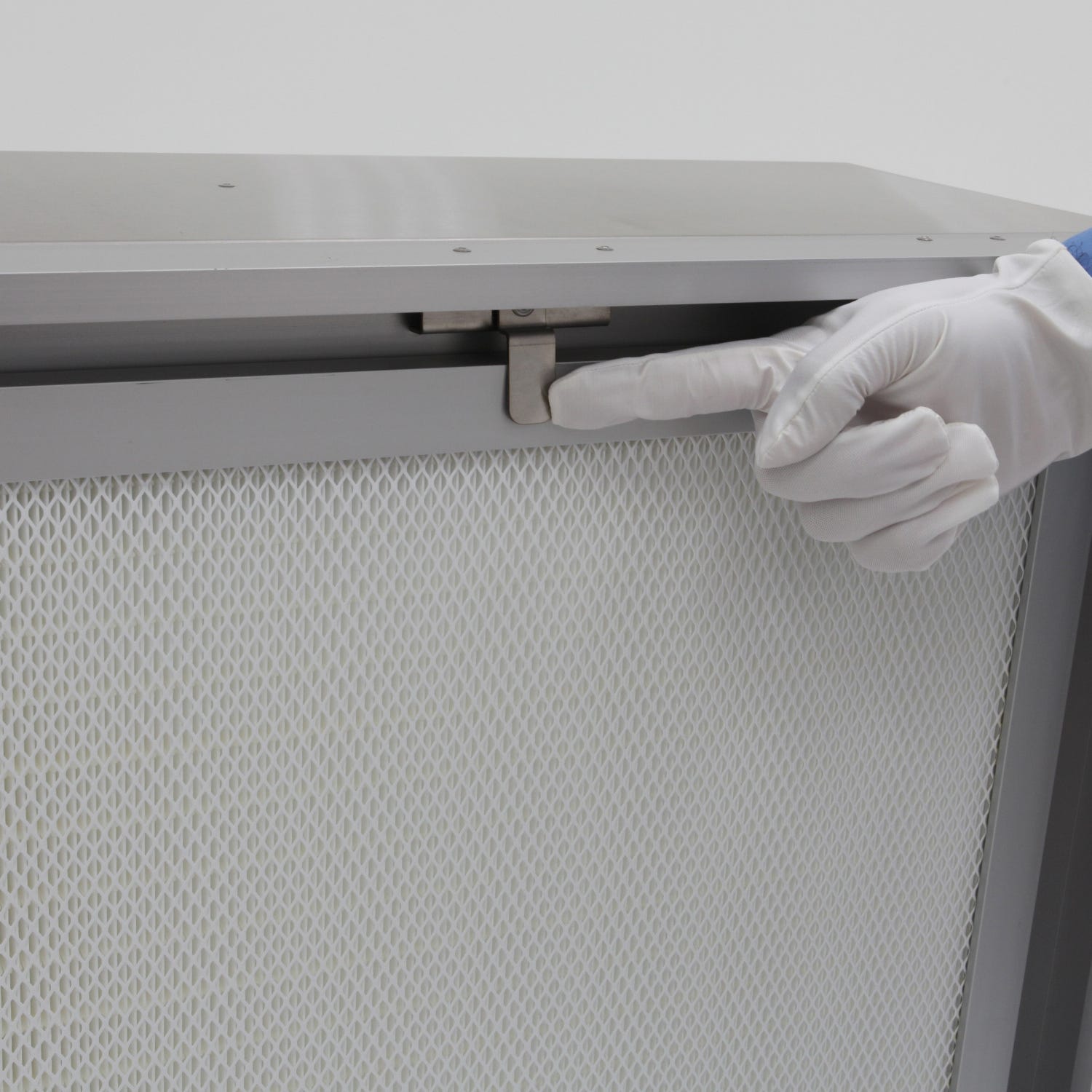

What is the difference between a Roomside Replaceable (RSR) FFU and Topside replaceable FFU?

Bench Top Replaceable Fan Filter Units

Standard FFUs with top-side replaceable filters are the lowest cost option and are ideal for small scale and less critical cleanroom operations. However, they have a disadvantage when installed in a cleanroom. In order to change the filter, FFUs with topside replaceable filters must be entirely pulled out of the ceiling bay. Climbing up to remove the bulky FFU can be difficult, dirty, and hazardous. The procedure may require tall ladders, multiple people, personal protective equipment, and perhaps worst of all, shutting down the cleanroom.

The cleanroom filter replacement process for top-side replaceable FFUs can put a complete stop on your cleanroom operations because the room ceiling will be breached. Dust and contaminating particles can pour in freely from the outside compromising the cleanroom’s cleanliness rating. In most cases, cleanroom operations halt until filters are changed and all HEPA filter blowers return to functional status.

Once the fan filter modules are placed back into the ceiling, depending on the required cleanliness classification, the cleanroom may need to undergo multiple step cleaning procedures with germicidal, fungicidal and sporicidal surfactants. Once these steps are complete, the air change rates can then be re-checked and recertified to fully restart cleanroom production. For critical operations, this type of shutdown could not only cost a fortune from lost time, but compromise cGMP operating standards and safety.

Room-Side Replaceable Fan Filter Units

Room-side replaceable (RSR) FFUs drastically simplify filter replacement to keep your cleanroom operations running smoothly. The HEPA filter of an RSR FFU is designed to be replaced from within the cleanroom, without dismantling the entire FFU. Filter replacement may still require a cleanroom ladder, but can be completed by 1 person; simply twist the retaining tabs to change out the filter, rather than pulling the entire FFU apart from the ceiling grid. With the fan filter unit still fixed to the ceiling, as long as other FFUs are running while one filter is being changed, the room can maintain positive pressure and keep outside contaminants from entering the space. This simplifies the filter changing process and minimizes downtime of your cleanroom operation.

For most cleanroom applications, room-side replaceable FFUs offer great savings by simplifying the filter replacement process to spare downtime and financial burdens. These savings multiply for cleanrooms with large networks of fan filter units.

How long does a HEPA filter last?

The life of a HEPA or ULPA filter depends on several factors such as ambient conditions, total operating time, fan speed setting (airflow rate), and maintenance of the pre-filters. On average, a HEPA filter can last three to five years. Some manufacturing industries insist on changing filters every two years regardless of their conditions. This can help avoid costly and unexpected cleanroom shutdowns.

Ambient conditions include how clean the outside air is, and how much moisture is in the air. Dirty outside air and moisture will shorten the life of the filter. The amount of operating time will also affect how frequently a filter needs to be changed. A filter operating 24/7 will need to be replaced more frequently than one operating half the time. Furthermore. a higher fan speed setting (higher air flow rate) will accelerate filter load compared to a lower speed setting.

One way to extend the life of HEPA filters is to recirculate the HEPA filtered air within the cleanroom. However depending on the type of cleanroom, recirculation may require additional ductwork and possibly more HVAC equipment to accomplish, which depending on the application may negate the cost savings from extended filter life.

As the filter loads over time, static pressure increases, and the filters actually become more efficient at capturing particles. However, this comes at the cost of diminished airflow which negatively impacts air change rate, and will eventually compromise the ISO class rating of the cleanroom or workspace.

How do you determine when to change a HEPA filter?

There are two common ways to determine when a filter should be changed:

- One of the easiest ways to check for cleanroom air filter replacement is by monitoring differential pressure. Most cleanrooms maintain a positive pressure environment. As the filter loads up, airflow drops, and so does the positive pressure in the cleanroom. Terra’s filter replacement alarm system simplifies this process for all clean room HEPA filters. The alarm unit connects tubing to one FFU to measure differential pressure and issues a warning alarm once differential pressure drops beyond a user defined setpoint.

- You can also measure air velocity coming out of the FFU to determine when a filter should be replaced. A minimum air velocity can be established by determining the desired ISO class of the cleanroom or working area. This method can be challenging as air velocity is not always uniform across all areas of the filter face.

How often do you need to change the pre-filter on an FFU?

The same ambient conditions that affect the lifespan of a HEPA filter apply to the pre-filter. A pre-filter has a smaller surface area, and catches the bulk of large particles in the air, so it may need to be changed as often as every one to three months in dirtier environments. Delaying replacement of a pre-filter can restrict airflow, negatively impacting the blower motor and output airflow of the FFU.

How can I order replacement filters and parts for my fan filter unit?

Terra Universal can supply replacement parts for most cleanroom filter systems we have manufactured. To identify the correct unit and the proper parts, please supply the unit's model number or serial number which is located outside of the motor housing. For more information, contact us and we’ll assist you with identifying replacement parts for your units.

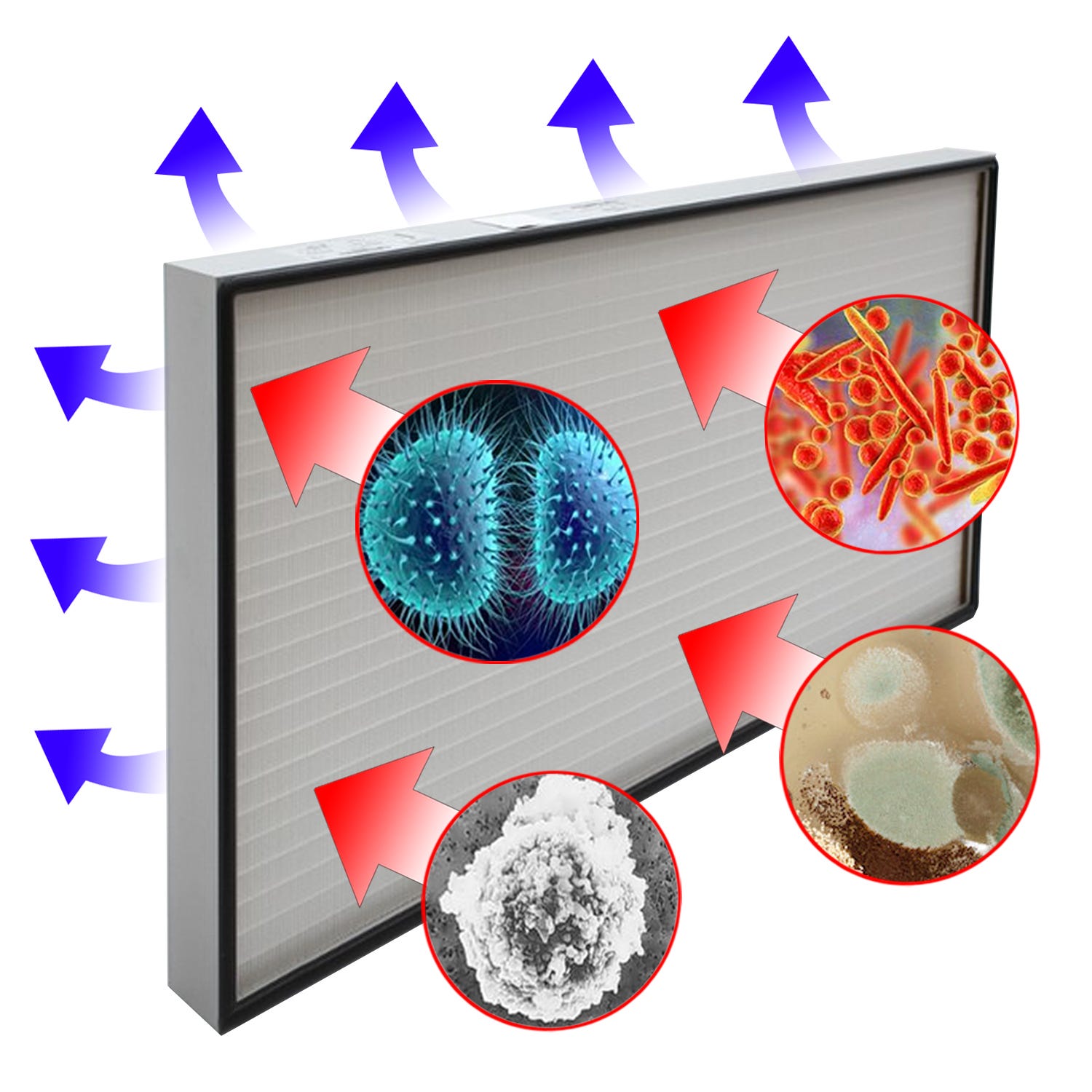

Can HEPA Filters Capture Coronavirus (COVID-19)?

A properly maintained air filter is a crucial piece of equipment in the fight against the SARS-CoV-2 virus. Both HEPA filters and ULPA filters reduce the number of microscopic particles in the air, which can keep air safe to breathe in places it’s needed most.

A HEPA (High Efficiency Particulate Air) filter is 99.99% effective at catching particles down to 0.3 microns. SARS-CoV-2 is 0.12 microns, so a HEPA filter cannot guarantee to remove all the tiny airborne viral particles. Still, HEPA filters are capable of capturing some portion of these smaller particles via methods of direct impact, interception, or diffusion. They can also effectively capture larger particles the virus might be clinging to that are in the 0.3 micron range. For instance, when COVID-19 hitches a ride on larger specks (large droplets or dust for example), both the virus and larger particle can get captured in the filter medium. For these reasons, many hospital air purifiers use HEPA filters to help mitigate the spread of infection in crowded areas such as hallways and patient rooms.

Many hospital air purifiers use HEPA filters, for example in hallways and patient rooms. Terra stocks medical grade HEPA filter fan units in a wide variety of sizes and configurations. These medical grade air filtration systems can be fixed in the ceiling for positive pressure recirculation, or in a reverse flow configuration to create a negative pressure environment such as an isolation room. A portable isolation room filtration system can easily roll between rooms in hospitals, clinics, and other confined areas. This mobile hospital air purification system is suitable for both recirculation and negative pressure, so it can quickly convert any room to a negative pressure isolation room.

What other types of air filtration protect against Coronavirus (COVID-19)?

An ULPA (Ultra Low Penetration Air) filter, on the other hand, is 99.999% effective at catching particles down to 0.12 microns. Yes, an ULPA filter can efficiently strip COVID-19 from the air itself. Because the filter medium is so fine, it reduces the speed at which air can flow through it, which may make ventilation a challenge. Many hospital air filters use ULPA filtration in operating rooms and intensive care units. Seriously ill COVID-19 patients are often treated in ICUs, and the particles hanging in the air there can be transferred via staff to other parts of the hospital if they are not contained. This is why medical air filters and hospital air filtration are so necessary to aid in the battle against COVID-19.

What are the benefits of UV-C sterilization with an FFU?

UV-C sterilizing modules can help fight against COVID-19 and other pathogens. The potential for UV-C sterilization to supplement other disinfectants in removing SARS-CoV-2 is promising. Terra Universal’s air filtration systems can house a remotely-accessed UV-C Sterilizing Module. The UV light helps clean the inside of the filter face to further protect against bacteria, viruses, and mold.

The light disinfects the surrounding environment by permanently damaging the DNA of any exposed germs, which kills them in the process. It is 99.9% effective at killing the viruses and bacteria it encounters. This could significantly reduce the chances of exposure to COVID-19 from open surfaces and ambient air, particularly if the UV-C Sterilizing Module is attached to a fan filter unit.

Read more on how fan filter units fight COVID-19

Can't find what you're looking for?Tell us what you need and we'll build it!