- Available ISO Ratings: ISO 7, ISO 8

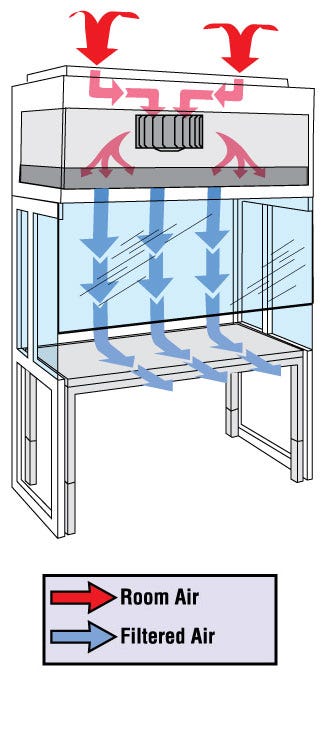

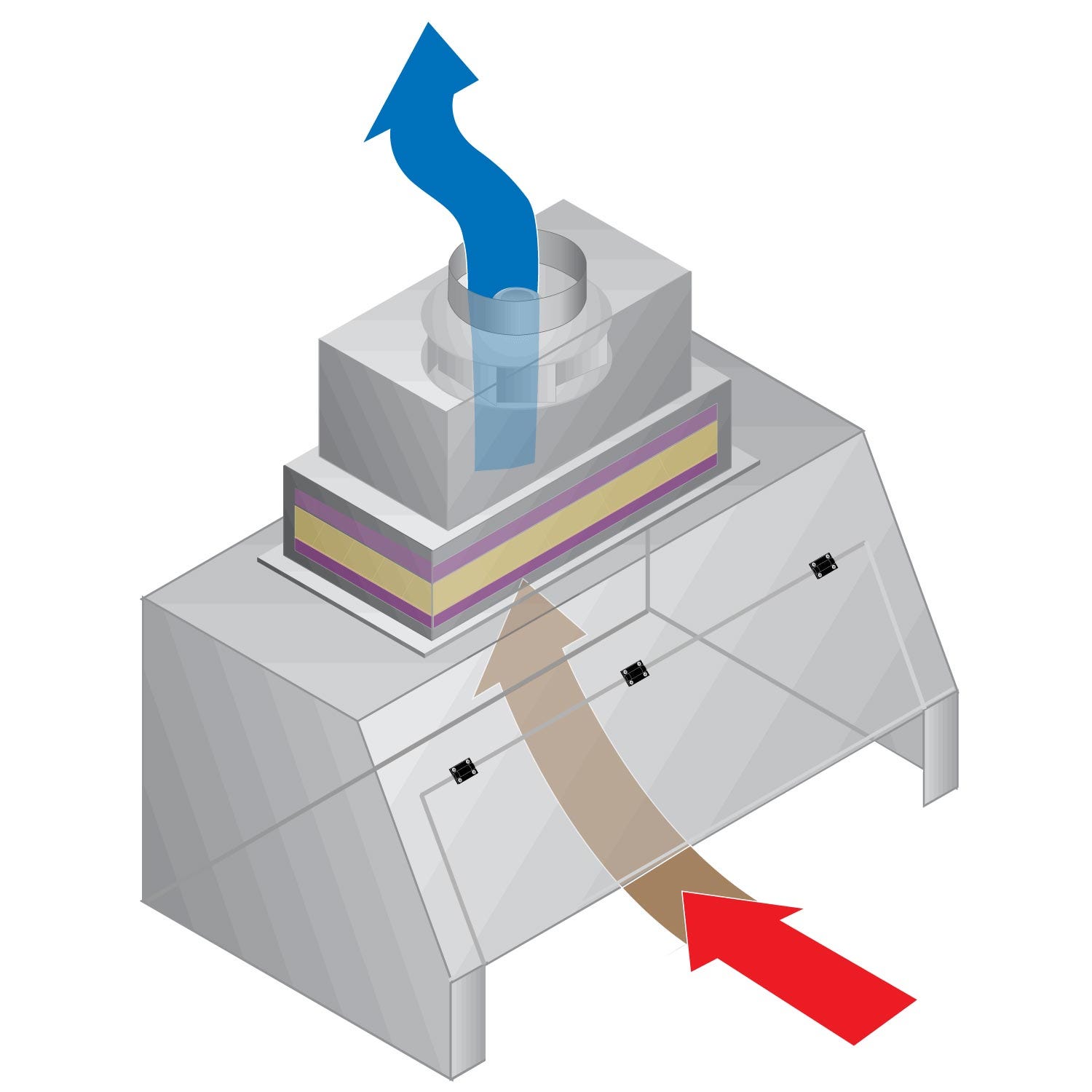

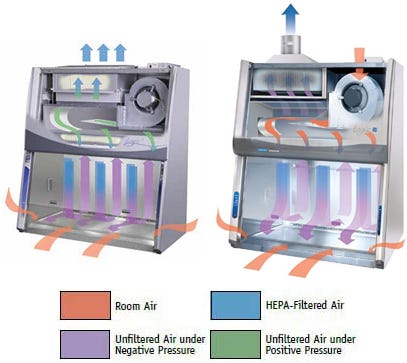

- Bi-directional exhaust system

- Fits above Terra's Wet Processing Station

- Cut outs on the back of the hood for the wet station exhaust flange

- Includes hood, controller, SDPVC side panels, and FFU

- Bench sold separately

• Airflow Design: Vertical

• Depth: 41"

• Hood Design: Floor

• Filter Type: HEPA, RSR

• Frame Material: Powder-Coated Steel

• Height: 90"

• Inside Depth: 32"

• Inside Height: 67"

• Inside Width: 45"

• Light Fixture: Fluorescent

• Manufactured by: Terra Universal

• Max Opening: 32" H

• Model: Wet Processing Station

• Side Panels: Static-Dissipative PVC

• Sash Design: Manual/Sliding

• Sash Height: 35"

• Sash Opening: 16"

• Width: 48"

• Work Area Dimensions: 45" W x 32" D x 67" H

• Unit of Measure: EA