- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

- Get a QuickQuote

- Free Consultation +1 (714) 578-6100

- Track Order Sorry, no orders are open for tracking

BioSafe Modular Cleanrooms,BioSafe Modular Cleanrooms,BioSafe Modular Cleanrooms,BioSafe Modular Cleanrooms,BioSafe Modular Cleanrooms

BioSafe® Cleanroom; 304 Stainless Steel

Custom-configured product: Please request quote. Terra will contact you for requirements.

Read more

Terra Part #: 6600-31

Manufactured By: Terra Universal

Warranty: 1 year parts, 90 days labor

Print

Want a quote quickly ?

Submit a QuickQuote request

6600-31

Terra Part # 6600-31

Request Quote

Usually ships in 25-31 business days

Want it faster ? Read about FasTrak

Accessories related to Terra Part #

6600-31

39707

BioSafe® Cleanroom; 304 Stainless Steel

Product Details

- Refer to sales order and/or drawings for dimensions and other details

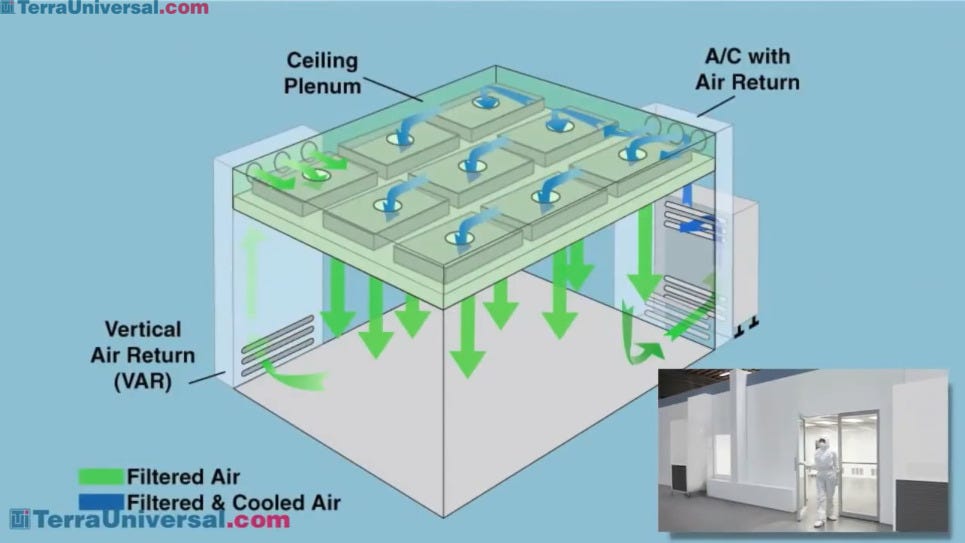

- Specified height is from the floor to filter face. FFUs add 13” (330 mm) overhead clearance to this measurement. To assure proper air flow and installation, allow an additional 11” (279 mm) between the top of the FFUs and the ceiling or other overhead obstruction (total of 24” (610 mm) between the cleanroom filter face and the surrounding facility ceiling).

- 304 stainless steel panels inside and out, use a unique, rigid double-wall design that requires no external bracing

- 1" (25 mm) radius corners eliminate voids, allow easy cleaning and disinfecting

- Includes 304 stainless steel ceiling grid (FFU and light supports) that forms 2' x 4' (610 mm x 1219 mm) bays for filter/fans, lights or blank panels (order ceiling modules separately)

- Standard exhaust register (one per 4'-wide panel) is 36" W x 10"H (914 mm x 254 mm), mounted 4" (102 mm) above floor

- Other options include access doors, windows, air conditioning, air locks and antechambers, air flow and pressure gauges, raised flooring, anti-microbial coatings, and furnishings

- Control Panel provides on/off switches for FFUs, lights and other system options, and includes Status Indicators(Order Separately)

- Request UL Listing Declaration (order separately) for cleanroom electrical system, which helps meet municipal and other permitting requirements that may apply

Manuals & Resources

Products similar to this one

Other products you may find relevant

-

Filter Replacement Alarm System; for Fan Filter Unit, Audible Alert, Manual Override, Stainless Steel, 120 V$1,496Usually Ships in 1 - 3 days

Filter Replacement Alarm System; for Fan Filter Unit, Audible Alert, Manual Override, Stainless Steel, 120 V$1,496Usually Ships in 1 - 3 days -

Portable Nitrogen Generator; Self-Contained With Compressor and Tank, 7.18" W x 16.08" D x 23.98" H$4,335Usually Ships in 3 - 5 days

Portable Nitrogen Generator; Self-Contained With Compressor and Tank, 7.18" W x 16.08" D x 23.98" H$4,335Usually Ships in 3 - 5 days -

Group of 21 productsErgoHeight™ Electric Height Adjustable Cleanroom Workstations FromAs low as $1,705Some ship in 1 - 3 days

Group of 21 productsErgoHeight™ Electric Height Adjustable Cleanroom Workstations FromAs low as $1,705Some ship in 1 - 3 days

Buy Accessories

BioSafe Modular Cleanrooms

-

Modular BioSafe® Cleanroom Installation

Modular BioSafe® Cleanroom Installation

-

Modular BioSafe® Hardwall Cleanroom

Modular BioSafe® Hardwall Cleanroom

-

Watch Terra's Portable HEPA Filtration System Video

Watch Terra's Portable HEPA Filtration System Video

Video demonstration of BioSafe® Cleanroom factory pre-installation

Modular BioSafe® Cleanroom Installation

Time-lapse installation of a modular BioSafe® steel cleanroom with windows, an exit swing door, entryway airshower and 50% ceiling coverage of fan/filter units.

Video overview of Terra's BioSafe® Biopharmaceutical Modular Cleanroom

Modular BioSafe® Hardwall Cleanroom

Video demonstrates why BioSafe® Modular Cleanrooms are ideal for bio/pharmaceutical applications requiring frequent cleaning and sterilization. Includes overview of accessory equipment.

Terra's in stock portable HEPA filtration systems provide high quality and medical grade air filtration for your ambient environment.

Watch Terra's Portable HEPA Filtration System Video

The mobile/ self contained filtration system converts to any room to a negative pressure isolation room which then makes it well suited for medical clinics, schools, waiting rooms and other confined areas.

Features and Benefits

Learn More: BioSafe Selection Guidelines

Print

Copy Copied

Negative-Pressure HD Storage Rooms

Ordering Information

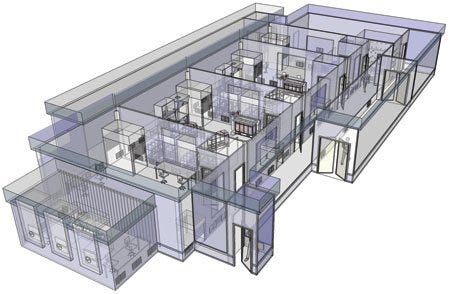

A complete BioSafe Modular Cleanroom includes fan/filter units, lights, and Terra's Power Distribution Modules (ordered separately), in addition to the standard cleanroom components (wall panels and ceiling grid) specified by the selected part number. Other options include pass-throughs, air conditioning modules and windows. Call to discuss your application with a Terra Product Specialist, or submit a QuickQuote request.

Declaration of UL Listing

For applications requiring UL-listed products, you may request a declaration of system listing under UL File E472687 at the time of order, which covers all high-voltage Modular Cleanroom electrical components integrated into Power Distribution System. This Declaration of UL listing helps meet municipal and other permitting requirements that may apply, while ensuring the safety and integrity of electrical components.

- Energy-saving mode saves 25% of fan operating costs by reducing power consumption during off-hours

- Maintains round-the-clock cleanroom integrity at lower cost

- Easy to activate via panel-mounted switch (Wireless Cleanroom Control System also available)

Terra cleanrooms are designed to meet a specified ISO cleanliness rating while in use: with operations in progress, process machinery humming, and personnel in motion. So why maintain that level of performance when a production shift ends and personnel leave for the day?

A cleanroom at rest maintains its target ISO cleanliness standard with much less airflow, fewer air changes—and decreased power consumption. Terra’s Night Service Switch activates a separate operation circuit that drops all Fan/Filter Units (FFUs) into low-energy operation mode, shaving 25% of energy costs from your power bill while maintaining uninterrupted cleanroom performance at your specified cleanliness level (see chart below). With Terra's Night Service Switch, operators can save up to 7,000 kilowatt-hours per year based on a cleanroom system utilizing 10 FFUs.

| Operation Setting | Airflow: cfm (m^3/hr) | Air Speed: ft/m (m/s) | Run Amps (Watts) |

|---|---|---|---|

| High Speed | 808 (1373) | 115 (.58) | 4.3 (512) |

| Medium Speed | 717 (1218) | 102 (0.51) | 3.5 (416) |

| Night Service | 654 CFM (1111) | 93 ft/min (0.47) | 3.3A (393W) |

Non-Sterile HD Compounding

Larger cleanrooms can be partitioned into multiple cleanroom space of different ISO classifications. The double-wall panel design allows BioSafe cleanroom walls to function as either interior or exterior walls, offering an equally clean surface on either side. Modular construction allows our engineers to more easily develop a custom solution at a reasonable price. Installation procedures also remain the same, resulting in fewer errors and delays.

For a higher degree of protection against contamination, personnel should enter a critical processing cleanroom through another controlled environment whenever possible. HEPA-filtered “buffer” rooms or hallways reduce particle counts immediately outside the cleanroom, lessening the impact of airflow turbulence caused by doors opening into the cleanroom. These clean corridors can also protect carts filled with work-in-progress as they move between processing rooms, such as when moving from quality assurance to the packaging phase. Gowning rooms often act as an anteroom, providing a space to transition from unclassified to controlled. For more functional transition options, see Terra’s air showers and tunnels, which use high-velocity air streams to remove loose particles from cleanroom garments prior to entry.

Accredited Technical Cleanroom Expertise

We are committed to provide our clients with a full service solution, from project planning through engineering, product design, manufacturing, procurement, shipping, installation, validation, commissioning, and preventative maintenance. Our team of qualified professionals collaborates with all stakeholders to deliver innovative solutions at every stage of the project.

BioSafe: Pre-Fabricated Cleanroom Parts

How can Terra offer industry-leading build times and pricing? Our advanced cleanroom design doesn’t require factory pre-assembly; each component fits together perfectly, ensuring seamless on-site installation

Long Running FFU Motors

Terra’s filter fan unit motors are rated for 5 years of continuous, 24/7 operation, if the HEPA filters are consistently replaced. To accurately monitor your HEPA filter’s saturation levels, purchase Terra’s audible and visual filter replacement alarm system.

Available Environmental Control System

Standard cleanroom comes with analog pressure gauge and on/off controls; optional touchscreen FFU controller monitors, controls and logs internal pressure, as well as displaying temperature and RH.

Smooth Interior Walls

Smooth steel BioSafe cleanroom panels with radius corners simplify cleaning and stand up to biocides and disinfectants. Cleanrooms constructed with medical-grade and USP-compliant material.

BioSafe®: Terra's Ultimate Cleanliness Rating

Terra's BioSafe products are designed for the most critical applications: no gaps and crevices where microbes colonize, rounded corners for easy disinfection, won't produce contaminants during sterilization, and exceeds cGMP, IEST, ASTM and ISO 14644-1 requirements.

Biosafe Cleanroom Exhaust Vents

Adjustable exhaust vents help balance internal room pressure inside BioSafe cleanrooms.

BioSafe Cleanroom Sterilization

Ceiling panel covers allow wash-down and sterilization of cleanroom walls and ceilings without damage to filter medium; requires BioSafe glass or stainless steel wall panels, which stand up to biocides.

Containment Exhaust Plenum

Negative-pressure containment cleanrooms include exhaust plenums that route air to floor- or ceiling-mount fans, protecting the external environment from hazardous materials inside the cleanroom.

Cleanroom LED Light Panel with Emergency Power Supply, 2' x 2'

Cleanroom LED lights are equipped with emergency back-up batteries to ensure continued operation in the event of a power failure.

Clean and Durable Powder Coat Finish

Terra’s signature white powder coat finish provides a high quality, durable barrier to protect against corrosion, plus a clean and attractive aesthetic. The advanced heat-fused formulation exceeds ASTM and ISO paint standards to resist chipping, scratching, fading, and wearing.

WhisperFlow Quiet Operation Reduces Distracting Background Noise

Exposure to loud noises can lower the ability to focus on work and listen selectively, which may also lead to safety issues. Typical AC units can be annoyingly loud, measuring in the range of 70 dB (comparable to a vacuum cleaner). Terra’s WhisperFlow design produces far lower noise levels for a quiet environment comparable to a library. At 90 ft/min output, units measure under 50 dB from only 1 ft away (roughly 75% quieter than 70dB).

Seismic Safe Cleanroom Design

Terra’s modular cleanrooms are designed with seismic safety in mind. Rigid steel frames and ceiling grids are designed with sufficient factors of safety to provide vertical and lateral strength recommended by professional engineers. Both hardwall and softwall designs can be installed to adhere to local seismic codes. Optional seismic and structural calculations can be drafted and stamped by a licensed PE to help meet municipal permitting requirements.

Highest Standards For Electronic Components

Terra’s electronic components are designed and built to the highest standards required by defense and semiconductor industries for long-term reliability and protection against damage, injuries, and electrical hazards.

Continuous Product Improvement

At Terra, we strive to develop and produce the highest quality products for our customers to improve health, safety, performance, and yields. Our product quality is enabled by high-grade manufacturing equipment and processes, 45 years of engineering and application expertise, and our commitment to continuously improve.

High-Throughput Cleanroom Manufacturing

Over the past 5 years, Terra has manufactured nearly 1,500 UL-approved cleanrooms at industry-leading build times. Terra’s versatile modular cleanroom frame and panel designs adapt to any floor plan requirement. The UL-rated and scalable plug-and-play power distribution system further simplifies installment of FFU's and lights to cleanrooms of any size.

4,000 Worldwide Cleanrooms

Since 1976, Terra has designed and manufactured over 4,000 cleanrooms for companies at the leading edge of high technology

Complete Order Transparency

Using Terra’s OnTrak system, our customers can view real-time production updates, receive shipment notifications and track their orders until they arrive at their facility

Products Compliant With Your ISO Rating

Provide Terra with your desired ISO rating. We will tailor the product to meet your rating and supply a certificate of compliance appended to your invoice, to be included in your compliance package. All certificates are archived in Terra's system for quick retrieval.

Popular Accessories

For a full list of accessories, select a product then click Choose Accessories on that product page.

-

Lighthouse Handheld Airborne Particle Counters

Lightouse portfolio of handheld airborne particle counters ensure accurate readings of cleanrooms and critical environments -

Germicidal UV Lamp Sanitizes Labs, Cleanrooms

UV-C Germicidal Lamp installs on a cleanroom ceiling grid for line-of-sight room disinfection; safety occupancy sensor prevents personnel exposure. -

BioSafe Windows

Double-pane, frameless windows mount flush with no external hardware, for smooth easy to clean surface. -

ISO-Compliant Hand Washer and Dryer

Terra’s ISO 6 cleanroom sinks offer touchless operation for compliance with aseptic protocols; shown with integrated HEPA-filtered hand dryer. -

Cleanroom UV Sterilization

UV-C sterilization modules can be installed in the ducting of a recirculating air flow configuration to reduce the bio-burden in an aseptic BioSafe cleanroom. -

In-Wall Utilities Plumbing

Plumbing for utilities can be easily installed within the BioSafe wall panels -

Roll-Up Door Pas-Through Chamber

Roll-Up Door Pass-Throughs with interlocked doors -

BioSafe Pass-through Chambers

Pass-through chambers, available for BioSafe Cleanrooms, include interlocked doors that allow contamination-free sample transfer. -

In-Wall Utilities Plumbing

BioSafe cleanroom panels allow flush-mount quick-connect fittings for vacuum, nitrogen, compressed air or other utilities.

Products similar to this one

Other products you may find relevant

-

Filter Replacement Alarm System; for Fan Filter Unit, Audible Alert, Manual Override, Stainless Steel, 120 V$1,496Usually Ships in 1 - 3 days

Filter Replacement Alarm System; for Fan Filter Unit, Audible Alert, Manual Override, Stainless Steel, 120 V$1,496Usually Ships in 1 - 3 days -

Portable Nitrogen Generator; Self-Contained With Compressor and Tank, 7.18" W x 16.08" D x 23.98" H$4,335Usually Ships in 3 - 5 days

Portable Nitrogen Generator; Self-Contained With Compressor and Tank, 7.18" W x 16.08" D x 23.98" H$4,335Usually Ships in 3 - 5 days -

Group of 21 productsErgoHeight™ Electric Height Adjustable Cleanroom Workstations FromAs low as $1,705Some ship in 1 - 3 days

Group of 21 productsErgoHeight™ Electric Height Adjustable Cleanroom Workstations FromAs low as $1,705Some ship in 1 - 3 days

PASSWORD REQUIRED

for

On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

- FasTrak 24/7 provides a 24/7 commitment to meet the shipping date YOU specify, regardless of quoted lead times.

- FasTrak 24/7 assigns a dedicated production team plus a dedicated senior expeditor working three shifts to meet your delivery specification.

- FasTrak 24/7 guarantees* to meet the agreed-to specified ship date.

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.