- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Cleaning & Sterilization Tips for the Cleanroom

Posted:

April 04, 2016

Whether lab technicians like it or not, cleanrooms are exposed to contaminants. Adulteration can occur from personnel, equipment, or even incorrect decontamination processes. Since many cleaning methods exist, it’s important to select one that’s best for your application; an careless technique may redeposit contaminants onto surfaces rather than take them away. Understanding particle-to-surface bonding (electrical, physical, or chemical) is one of the first steps to optimal cleaning efficiency. Keep reading for more tips that ensure your cleanroom remains clean.

Basic Types of Cleaning

“Wet cleaning” removes contamination with the use of a cleaning fluid. In some cases, wiping will move particles, but fail to remove them. Therefore, wet cleaning is typically implemented when wiping is not enough to overcome the particle adhesion. Cleaning solutions include a number of chemical choices; based on the surface material and whether disinfection or sterilization is the goal will determine the type of chemical(s) required.

Non-shedding, absorbent wipes

“Dry transfer” is the polishing and/or wiping of a surface using a collective or absorbent material. Since the point of cleaning is to sanitize, reducing the possibility for recontamination is essential. Cloths and wipes should consist of durable materials that will not redeposit particles, shed fibers, or easily break apart. Your cleanroom’s ISO class will establish whether knitted polyester or more absorbent cotton twill wipes are necessary.

Cleaning Equipment

Wet cleaning and dry transfer can only go so far; for a more rigorous disinfection or sterilization, some cleaning equipment may be better-suited to the task. In cleanrooms requiring an aseptic environment, ultraviolet (UV) irradiation is used to sterilize large areas, rendering pathogens harmless by destroying the microorganisms’ DNA.

Autoclaves sterilize laboratory supplies, equipment components and some liquids by steam-cleaning, using high pressure and heat. The pressurized enclosure raises the temperature of water to above its boiling point so that the steam holds more heat, making the autoclave efficient at killing most microbes.

Vaporized hydrogen peroxide (VHP) bio-decontaminate using a sporicidal solution that is deposited onto surfaces. VHP systems are compatible with sensitive electronics and provide quick and effective neutralization of biological agents and category III and IV pathogens. A VHP unit will disperse vapors in large environments like cleanrooms and laboratories, or small enclosures such as glove boxes; however, hydrogen peroxide vapors are harmful to humans when inhaled, so units should only operate during off-hours to ensure personnel safety.

Hand-held dry-Ice cleaner

If surfaces or equipment are sensitive to moisture, non-abrasive dry ice “blasting” can be performed in a nitrogen-rich environment to remove contaminants. High-precision dry ice guns use an intense, pressurized stream of carbon dioxide (CO2) to dislodge particles. The solid CO2 sublimates, and as a result no chemical residue is left behind; contaminants are carried away by the flowing “ice” air stream.

For submicron particle removal, high-frequency ultrasonic cleaners will handle anything from the most delicate of substrates to the more difficult industrial equipment without causing damage. Sound waves create bubbles in water- or chemical-based liquid solutions, which release “scrubbing” energy when they burst. Add heat for a more powerful cleaning result.

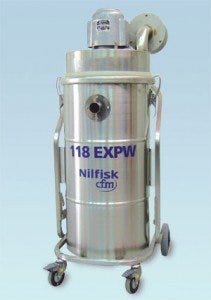

Cleanroom Vacuums are fundamental to cleanroom cleanliness. They use HEPA or ULPA filters to capture and remove particles from the controlled environment. Interchangeable attachments allow personnel to clean flat surfaces and hard-to-reach areas such as corners and crevices. Many are designed for hazardous dry or wet material clean-up with grounding wires and non-sparking motors to prevent explosions from dust or flammable liquids.

Explosion-proof vacuum cleaner for working with flammable material (by Nilfisk).

Cleaning Tips

Here are a few tips to help maintain the high standards of your cleanroom:

- Employees should treat cleaning just as carefully as they would “normal” cleanroom operations. Proper gowning and slow, controlled movements limit introduction and disturbance of contaminants.

- Avoid exposing your processes to outside contamination by ensuring that items coming into the cleanroom are cleaned/disinfected before entering. This includes, but is not limited to, equipment, tools, parts, and (the biggest offender) personnel.

- Built-up cleaning fumes may also contribute to particle accumulation. To reduce this risk, keep fan/filter units operating while you clean.

- If you’ve decided wet cleaning and/or dry transfer are the best options for your critical area, wipe/mop in a slow, controlled overlapping pattern that pushes the particles in the same direction as the room’s airflow. Using a rapid motion while wiping may charge the surface or equipment, producing electrostatic bonds that can attract particles.

- Floors are one of the most easily contaminated areas of a cleanroom since gravity naturally pulls contaminants down. Shoe cleaners and sticky floor coverings/mats will minimize the number of particles before they are tracked into your controlled environment.

- How you clean is just as important as what you use while cleaning. Even though they are small, microscopic particles are affected by gravity: clean shelves first and save the floor for last. This ensures that falling particles do not re-contaminate newly cleaned surfaces.

Practicing proper cleaning methods and providing personnel with suitable cleaning supplies will positively influence the quality and results of your cleanroom processes. Check your facility’s standard operating procedures for required cleaning frequency, but also use common sense: if it’s been exposed to contaminants or looks dirty, clean it! For more information about cleanroom sanitizing and decontamination, visit cleaning equipment.

Read More: Steps & Tips for Stainless Steel Cleaning

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731