- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

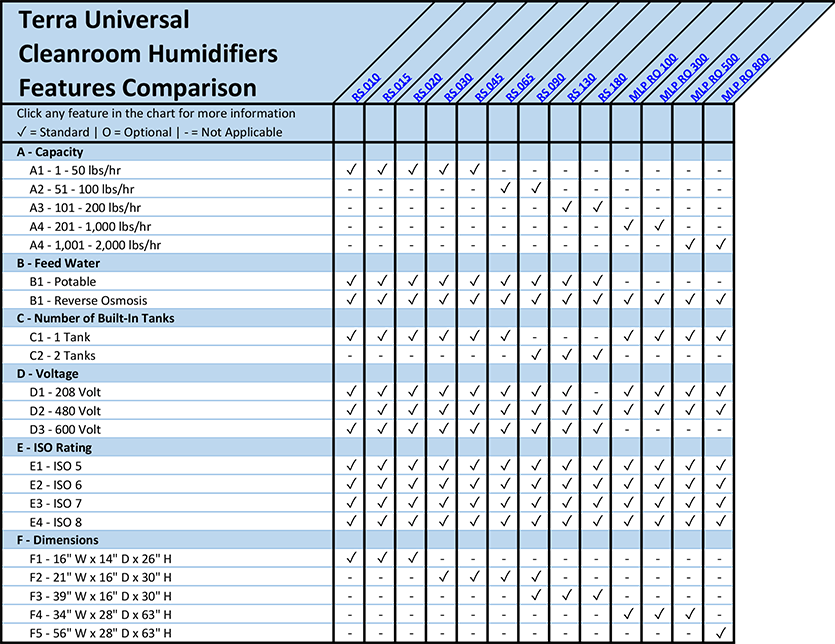

In critical cleanroom sectors such as pharmaceuticals, biotech, and electronics, precise humidity control is essential for protecting equipment, process consistency, and components. This post examines several high-performance attributes of cleanroom humidifier systems offered by Terra Universal.

Cleanroom humidifier performance is determined by several factors including capacity, feed water quality, built-in tank storage, and hygienic features required to support ISO-rated environments (deposits and scale management). Integral humidifier systems are commonly deployed within central HVAC systems or deployed in specific locations for individual room control.

Typical cleanroom humidity falls between 30-60% at room temperature, but this is not always the case. For instance, the printing of diagnostic strips using water-based inks can require a high humidity of between 95-98 %RH, and a variance of only ±1%RH. In such circumstances, when the optimum humidity must be precise, it is extraordinarily difficult to maintain the entire room at such levels, therefore micro-climates and additional humidification systems are often constructed around individual manufacturing areas or equipment assemblies.

Resistive humidifiers, such as the Nortec RS series, create steam through the transfer of heat from the heating element to the water. This is unlike electrode boiler humidifiers that pass electrical current through the water. This unique heating system has several benefits when compared to less sophisticated systems including elimination of disposable plastic cylinders and cleanable metal cylinders that significantly reduce operating costs.

Resistive humidification systems generate a steam output that is controlled by applying more or less heat to the water rather than controlling water level or conductivity. Resistive humidifiers can operate on RO water and the mineral content of the water has no impact on steam output, This virtually eliminates scale build-up, thus reducing servicing, and improves humidity control by removing the need for mineral dilution cycles to control foaming. The result is a responsive and precise humidity control of ±3%RH, or ±1%RH with reverse osmosis water (RO). Reverse osmosis water eliminates 95% of minerals from the supply water, which reduces maintenance and improves humidity control.

Scale Collection Technology: Nortec RS systems include a patented scale collection technology. This system combats scale buildup in steam cylinders by continuously collecting and storing deposits in a removable, easy-to-maintain tank, extending equipment lifespan and reducing maintenance needs.

Terra offers several cleanroom humidifier systems including Nortec RS Series and MLP RO systems by Condair.

Nortec RS series steam humidifiers are designed exclusively for air humidification via a steam distributor or a Condair blower pack appropriate for the specified operating conditions. Direct steam RS models include blower packs for direct-room humidification, while indirect steam models without blower packs utilize the building's existing steam distributor.

Direct Steam Nortec RS Humidifiers With Blower Packs: Operates on the resistance heating principle and is designed for direct room air humidification (with blower pack)

Direct Steam Mechanism: Direct steam humidification injects directly into the room or air duct system where humidity control is required. The steam immediately mixes with the air, increasing its moisture content.

Direct Steam Applications: Common for industrial processes, healthcare facilities, and commercial buildings where rapid humidity adjustment is necessary, and the direct introduction of steam doesn't pose a risk to the processes, equipment, or occupants.

| Specification | Nortec RS 010 | Nortec RS 015 | Nortec RS 020 | Nortec RS 030 | Nortec RS 045 | Nortec RS 065 | Nortec RS 090 |

|---|---|---|---|---|---|---|---|

| Capacity* (lb/hr) | 0-11.4 | 0-17.6 | 0-22.8 | 0-31.8 | 0-47.9 | 0-71.9 | 0-95.4 |

| Input kW max | 3.9 | 6.0 | 7.7 | 10.8 | 16.3 | 24.5 | 32.1 |

| Number of tanks | 1x small | 1x small | 1x small | 1x med | 1x med | 1x med | 2x med |

| Built-on Blower Packs | yes | yes | yes | yes | yes | yes | no |

| *Rated capacity will vary based on the particular unit configuration. | |||||||

Indirect Steam Nortec RS Humidifier Models Without Blowers: Indirect humidification (with steam distributor) that is designed for integrated use within the HVAC system.

Mechanism: Indirect steam humidification involves using steam to heat water or a wetted element inside an air handling unit or duct, which then evaporates into the air stream, increasing humidity without direct steam contact.

Applications: Ideal for cleanrooms, laboratories, and other environments where air purity is crucial, and any introduction of impurities must be avoided.

| Specification | Nortec RS 090A | Nortec RS 130 | Nortec RS 180 | |

|---|---|---|---|---|

| Capacity* (lb/hr) | 0-95.4 | 0-143.2 | 0-189.3 | |

| Input kW max | 32.6 | 48 | 64.2 | |

| Number of tanks | 2x small | 2x small | 2x small | |

| Built-on Blower Packs | no | no | no | |

| *Rated capacity will vary based on the particular unit configuration. | ||||

Terra recommends the MLP RO humidifier series by Condair because it combines a high-pressure pump station with a reverse osmosis (RO) system and hygienic humidification. This pre-assembled, easy-to-install solution removes over 95% of salts and minerals from tap water, ensuring optimal performance in your humidification application.

Given the significant airflow requirements of clean rooms, in-line or standalone humidification systems are often required to increase humidity levels and maintain specific RH% targets. Several factors will influence the size and sophistication of these systems including air capacity requirements, relative humidity tolerances, and climate. Humidifiers are particularly vital in sectors such as pharmaceuticals, biotechnology, healthcare, and electronics manufacturing, where a stable environment is essential for the protection of delicate equipment and products. Additionally, humidifiers help to maintain comfortable working conditions and prevent uncomfortable side effects of ultra-dry air such as dry skin, stuffiness, and static cling. Because temperature and humidity are related, it's crucial to consider additional heat sources in the cleanroom that emanate from heat-generating equipment and the human body.

Biopharmaceutical manufacturing: Precise humidity control ensures the quality, consistency, and stability of powder-based products. Air that is excessively dry can lead to powders becoming overly desiccated, allowing them to become airborne and remain suspended for extended periods. Conversely, overly humid conditions can compromise the powders' characteristics, potentially impacting the efficacy of the end product. Achieving specific humidity targets is therefore crucial, as even minor deviations can significantly influence the behavior and quality of powders and supplements in these sensitive environments.

Continue To: Cleanroom Humidity and Temperature Control Strategies

Pathology and Epidemiology: Humidity levels are a significant factor when evaluating the survivability of microbes on various surfaces, especially surfaces with inherent antimicrobial properties such as copper and silver-coated surfaces. Studies by Kaur et al. reveal that relative humidity and organic matter conditions influence the rate of bacterial decline, with higher humidity and organic content correlating with more rapid bacterial reduction.

Stability & Shelf Life Testing: In specialized environments for stability testing and shelf life analysis, humidity requirements may exceed 75 %RH. Therefore, these facilities are likely to require additional humidification systems that can achieve conditions more akin to humidity levels found in natural climates.

Printing & Textiles: In the printing industry presses must self-feed paper evenly, one sheet at a time at very high speeds. When the static electricity causes sheets of paper to stick together, the paper bunches, the feeding becomes uneven, and eventually, the paper jams the presses. In the textile industry, static electricity causes the yarns to adhere to each other, the shuttles miss threads and improper weaving patterns result.

Offices: Dry environments tend to generate static electricity, especially when combined with fast-moving conveyors and feed systems that generate friction and static discharge. In high-speed printing assemblies, sheets of paper stick together and jam the machine leading to downtime, increased operating costs, diminished quality control, and reduced profitability. Humidification systems allow for the attunement of the production environment to an ideal humidity that is high enough to prevent static generation, yet low enough to prevent issues caused by excess moisture in the air such as mold, mildew, or condensation.

Computer rooms and data processing areas: The lack of humidity results in static electricity that causes problems such as circuit board failure, dust buildup on heads, and storage tape breakage. Static electricity can also be dangerous. Sparks caused by static are extremely hazardous in locations such as hospital operating rooms where flammable gasses are present. Many flash fires – even explosions - are caused by static electricity.

Electronics & Static Prevention: Levels of humidity below 40%RH can lead to static build-up, which presents an immediate risk to sensitive electronic components and circuit boards if not properly mitigated. Because room air is especially dry in electronics facilities, humidifiers may be required at certain stages of production to reduce static generation and discharge events during the handling of plastics, films, and packaging. A humidity level of between 55-65%RH will significantly reduce the probability of electrostatic discharge while also preventing the ignition of flammable gasses or substances due to static-generated sparks.

Tablet Coating: Successful coating of a tablet largely depends on the composition of the tablet at the time of exposure to its coating. If the tablet’s surface is too dry, due to incorrect humidity levels, the coating will not adhere correctly. Likewise, if the humidity post-coating is not optimal, the coating may dry too rapidly, detrimentally affecting its properties.

The capacity of cleanroom humidifiers is a critical factor that determines their ability to maintain desired humidity levels. Terra offers several models that cater to small or large areas with outputs of 10-180 lbs/hr. These capacities are categorized as follows:

Suitable for small to medium-sized cleanrooms, ensuring precise humidity control within tightly regulated environments.

Designed for larger cleanrooms, these units provide increased moisture output to accommodate more extensive spaces without compromising humidity accuracy.

For even larger spaces, these humidifiers offer a balance between high moisture output and efficient operation, ideal for extensive cleanroom facilities.

High-capacity units for industrial-scale applications, ensuring optimal humidity levels across vast cleanroom areas.

The highest capacity range, engineered for the most demanding cleanroom environments, delivering superior moisture control.

The quality of feed water is crucial for the efficient and reliable operation of cleanroom humidifiers. The common types of feed water include:

Potable water-fed humidifiers are versatile and easily integrated into existing cleanroom infrastructures, suitable for a wide range of applications. Potable water may still contain certain levels of dissolved minerals, chemicals, and other impurities.

Nortec RS-Series Humidifiers are configurable for use with potable or DI/RO water. For potable water applications, the unique scale collector tank option saves time and money during maintenance. The scale tank collects minerals and is easily removed for disposal of scale.

Nortec RS 045 Steam Humidifiers have internal steam cylinders, external scale removal tanks, and a built-in blower pack for direct room humidification. The external collection tanks (sold separately) allow for easy access and removal of scale deposits

RO water reduces mineral buildup and maintenance requirements, enhancing the performance and longevity of humidification systems. Reverse osmosis water undergoes a filtration process that forces water through a semipermeable membrane, thus removing a vast majority of dissolved solids, contaminants, and impurities, including bacteria, viruses, and chemicals.

MLP RO 500 High Pressure Humidifiers with external tanks produce RO water, and pressurize storage water at 1000 PSI for humidifier feed water supply.

Cleanroom humidifiers are configurable with one or more corrosion-resistant stainless steel and may cylinders to support higher capacity and streamlined maintenance:

Single-cylinder systems are compact and efficient. Stainless steel components are ideal for cleanrooms where hygiene and space optimization are crucial.

Nortec Dual-cylinder systems offer continuous operation, with one tank in use while the other is being refilled or maintained, reducing downtime.

Single cylinder configurations offer humidification capacities of up to approximately 88.18 lbs/hr. For higher output, the double cylinder model delivers humidification up to 176 lbs/hr. For max output, four single units can integrate into a parent/child slave configuration, collectively achieving humidification outputs of approximately 352 lbs/hr.

MLP RO packages include models with external water tanks, as others with a 2-in-1 system that functions as a combined humidifier reverse osmosis feed water generator. Module sizes vary to match humidification volume, and several packages are available without the reverse osmosis if a RO water source is already available.

The MLP RO comes in four basic models, MLP RO 100, 300, 500 and 800.The number indicates the maximum continuous water outlet (high-pressure) in liters per hour at 59 °F (15°C) (tap water temperature).

MLP RO 500 and 800 series models include holding tanks are placed on separate frames (52 gallons (200 l) (200 l) and 132 gallons (500 l) (500 l) respectively).

Voltage requirements must align with the facility's electrical infrastructure to ensure the safe and efficient operation of cleanroom humidifiers:

D1 - 208 Volt: Suitable for smaller to medium-sized facilities, these systems integrate seamlessly into existing electrical setups.

D2 - 480 Volt: For larger industrial applications, 480-volt humidifiers offer robust performance required for extensive cleanroom environments.

D3 - 600 Volt: Designed for the largest and most power-intensive applications, ensuring reliable humidity control in high throughput cleanroom settings.

Shop Terra Universal products online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra Sales Specialist via phone, webchat, or email for help with configuration, large purchases, or application expertise.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Call (714) 459-0731