- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Cleanroom Design and Construction Services: Dedicated Expertise or DIY?

Posted:

March 14, 2024

Categories:

Cleanrooms

On average, Terra Universal designs over 500 cleanrooms annually. Over the last six years, that equates to the successful construction of over 2,100 cleanroom environments. When it comes to sourcing a cleanroom design provider, experience is a trademark of a timely and successful cleanroom build. Here, we'll outline a variety of starting points to kick off your cleanroom design journey including DIY tools, cleanroom design principles, Terra's design philosophy, and solutions for common cleanroom construction challenges.

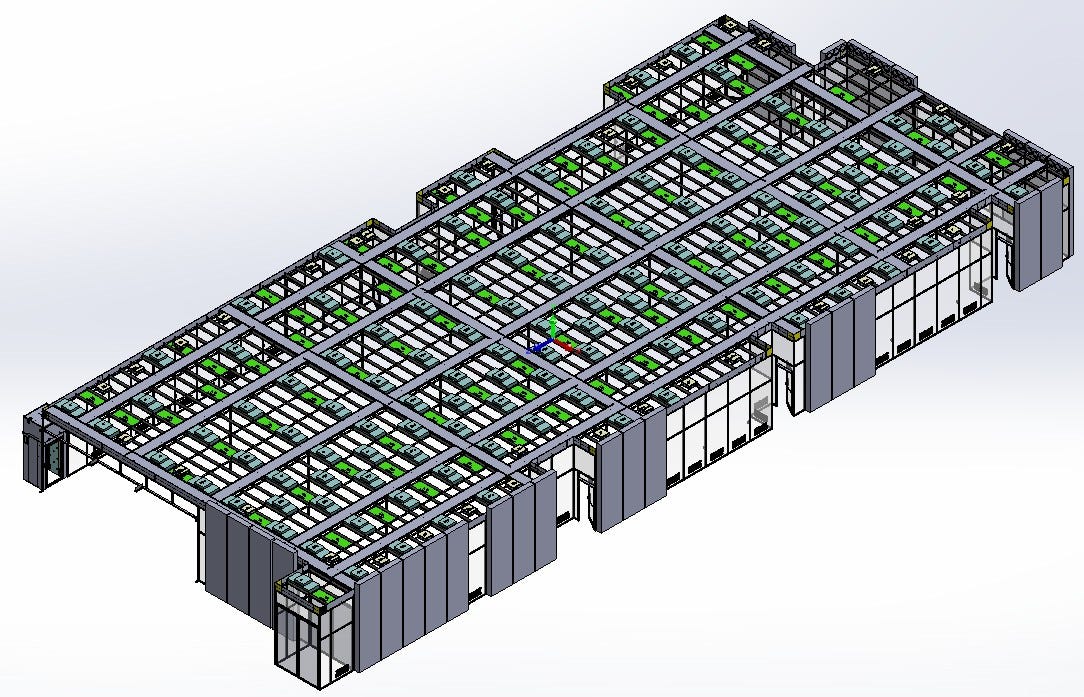

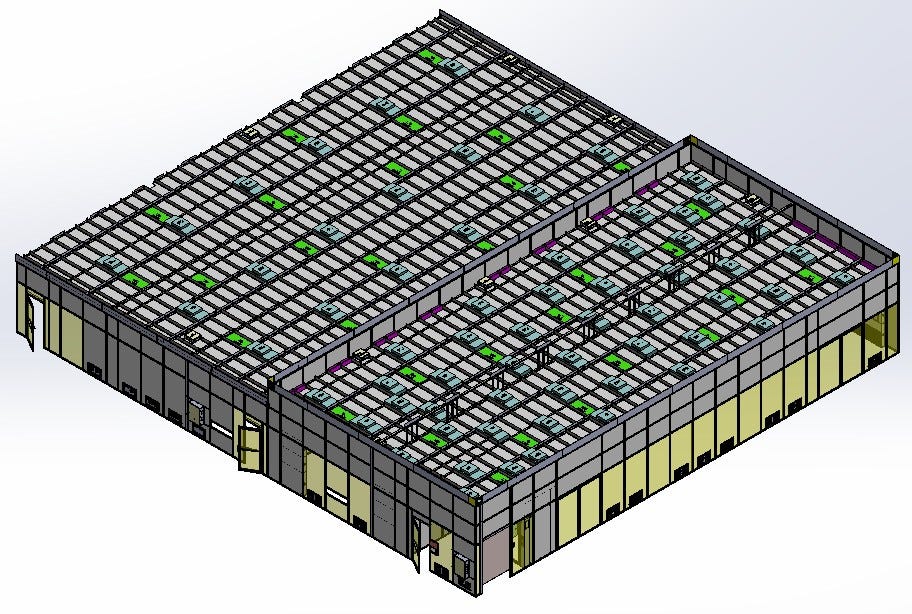

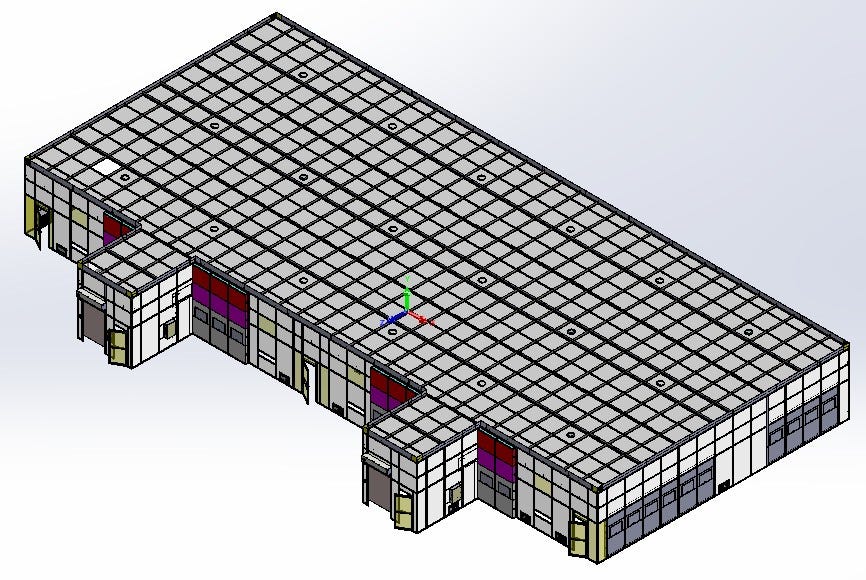

Modular & Prefab Cleanroom Design Approaches

Not every customer requires a custom-designed cleanroom. For those who seek prefab (prefabricated) cleanroom designs, Terra offers several in-house solutions and ready-to-ship solutions in hardwall and softwall styles. Terra's modular cleanroom designs emphasize flexibility and adaptability, recognizing that no single solution suits every application. Should your needs evolve, Terra's systems are designed for seamless integration of enhancements such as additional filters, lighting, ionization, or expanded floor space. This modular approach ensures that upgrades and expansions can be implemented economically, avoiding the substantial costs often associated with modifications to traditional cleanroom systems.

Terra's modular cleanroom designs and components provide a complete system of UL-listed products that are optimized to speed up installation, streamline specifications, and simplify final certification and validation. Starting from the ground up, Terra's all-in-one modular cleanroom systems are available in softwall, hardwall, BioSafe®, and specialty packages.

- Hardwall Modular Cleanroom Designs

- Softwall Modular Cleanroom Designs

- BioSafe Modular Cleanroom Designs

DIY Cleanroom Design: Try Terra's Free Online Cleanroom Design Software Tool

Terra's browser-based cleanroom designer app allows for custom cleanroom planning and design. This DIY tool enables you to design and conceptualize your cleanroom in a few easy steps, and immediately generates a price quote for the assembled enclosure and components. Emphasizing collaboration and efficiency, users can share their cleanroom designs with peers and colleagues. This functionality simplifies feedback collection and consensus building while moving toward a final design.

Cleanroom Designer Access -> Sign In or Create a Terra Account

Your profile provides secure, confidential access to

- Unlimited free access to Terra's Cleanroom Designer 3D

- Unlimited free storage of your 3D cleanroom models

- Access your cleanroom designs through the Account Dashboard

- Your quote and order history

Continue to; Cleanroom Installation Methods, DIY Strategy, and Planning Tips

Terra Cleanroom Design Principles, Approaches, and Expertise

Practical cleanroom design demands a multidisciplinary strategy that harmonizes architecture, design, and construction principles with respect to client-specific workflows and essential compliance standards. With over four decades at the forefront, Terra has spearheaded innovations in cleanroom design and technology, setting industry benchmarks with its custom and prefabricated solutions. These systems epitomize rapid deployment, scalability, and streamlined compliance, solidifying Terra's reputation for the industry's best delivery times. Combining high-throughput, automated fabrication equipment with a robust, active stock of raw materials, Terra is capable of producing cleanrooms of any design, size, scope, and complexity at industry-leading build times.

Continue to: Cleanroom Designs that Terra Recommends

ISO-14644-4 Cleanroom Design & Construction

Terra's cleanroom solutions not only adhere to but surpass the stringent ISO 14644-1:2015 standards, which delineate air cleanliness classifications in cleanrooms and zones. Crafted in our Fullerton, California facilities, Terra's portfolio includes five distinct cleanroom configurations, providing unparalleled adaptability for various requirements across ISO 4 to ISO 9 ratings. Our approach involves meticulous pre-engineering of components, rigorous quality assurance processes, and a well-stocked inventory, enabling our engineering teams to promptly respond with same-day quotes and rapidly transform project specifications into ready-to-manufacture solutions that meet and exceed requirements set by ISO 14644-1:2015 standards.

Continue to: ISO 14644 Cleanrooms & Components | Comparison & Features Guide

Cleanroom Design & Installation Challenges

It's important to understand the nature and relationship of your cleanroom provider in regard to the sourcing and delivery of the cleanroom enclosure and associated components. Each additional third-party element introduces the potential for miscommunication, delayed timelines, and increased complexity in project management.

Quality Control Issues: With multiple entities involved, ensuring uniform quality standards across all aspects of the cleanroom build becomes challenging, risking subpar installations or equipment.

Increased Complexity in Project Management: Managing a network of specialized service providers and suppliers requires sophisticated coordination and oversight, adding layers of complexity to project management.

Integration Difficulties: Ensuring that all outsourced components and systems work seamlessly together can be problematic, potentially leading to operational inefficiencies or compatibility issues.

Cost Overruns: The involvement of multiple third-party providers can lead to unforeseen expenses, arising from coordination issues, rework, or extended timelines, impacting the overall budget.

Accountability Concerns: Determining responsibility for specific aspects of the project can be complicated, making it difficult to address and fix issues or defects.

Prefabricated Limitations: It's important to understand the limitations of prefabricated systems. The downside of prefabricated solutions is that they tend to lack flexibility for builds that require unique geometries or ceiling heights that rise above 8 - 9 feet. Prefab cleanroom designs have several restrictions and limitations that custom cleanrooms do not, such as limited design freedom for internal corridors and pathways. Custom designs are not limited by maximum distances between wall-to-wall spans or ceiling heights.

Overcoming Cleanroom Design Challenges: Terra Expertise & Solutions

For customers, the advantage of Terra's in-house expertise is twofold. Firstly, it significantly reduces the risk of inconsistencies and delays that arise in planning and design stages. Secondly, Terra's comprehensive understanding of both the design and manufacturing aspects of cleanroom systems allows for more effective project management, minimizing the complexities that often accompany coordination with various third-party vendors.

In the initial design stages, Terra works to align the cleanroom's preliminary and detailed designs with the end-user's specifications and prevailing industry norms. This involves the selection of suitable materials, HVAC configurations, filtration systems, and spatial planning to achieve the requisite cleanliness standards and operational effectiveness.

Initial Engineering Drawings Provided With Every Cleanroom Build: negates the additional costs and delays typically associated with using external engineering firms. Clients benefit from direct access to Terra's engineering and fabrication expertise and reduces the constant stream of emails and phone calls that are otherwise required when working with outside entities.

Robust Manufacturing Capabilities are the cornerstone of Terra's service offering. Combining high-throughput, automated fabrication equipment with a robust, active stock of raw materials, Terra is capable of producing cleanrooms of any design, size, scope, and complexity at industry-leading build times. Deep inventory sources minimize production delays that cause manufacturing lag times. This aspect of Terra's operation is essential for maintaining a swift turnaround time for design and architecture deliverables, even when late-stage changes to the build scope occur.

Future Proofing: Terra's service continuity also ensures improved compatibility and capabilities for future expansions or new builds. Clients expanding their operations or constructing new facilities can do so with the confidence that comes from working with a consistent engineering team already familiar with their existing operations.

Manufacturer Direct Support: extends to troubleshooting, maintenance, and installation services, offering a comprehensive support system. This support system is designed to eliminate the often costly and time-consuming need for third-party consulting, thereby reducing repeated expenditures.

Designed for Faster Permitting & Inspection: Terra's UL-Listed Control Panels and Power Distribution Modules (PDMs) are specifically designed to simplify electrical connections, reduce headaches, and get cleanroom projects completed and certified faster. Each PDM accommodates up to 5 lights and 5 FFUs and must be wired to a dedicated 35A fused 120V circuit or a 30A fused 240V circuit. Quick-Connect Fittings eliminate hardwiring for the connection of lights, fan filter units, and duplex outlets. Quick connectors reduce the complexity and frequency of electrical touchpoints and allows the installation of powered cleanroom components without requiring the assistance of a licensed electrician.

Continue to: Cleanroom Power Distribution Units: A Simpler Method for Cleanroom Electrical Design

Single Source Equipment Outfitting: As the leader in critical environment solutions, Terra also manufactures laminar flow hoods, desiccator cabinets, glove box isolators, pass-through chambers, and a broad array of cleanroom-compliant furniture, storage and gowning equipment.

Qualification, Certification, and Value-Added Services: In addition to product manufacturing, Terra offers a wide range of value-added services, including white glove delivery, cleanroom installation, structural seismic analysis, expedited production, qualification documentation, and extended warranties. Qualified cleanroom orders are available with specific certificates of compliance that list each product’s adherence to ISO, UL, OSHA, and seismic standards.

Terra Cleanroom Design & Planning for Architects, Builders

Terra provides highly specialized cleanroom enclosures and components for end-to-end cleanroom design and construction projects. Ease of installation, in-stock products, and QuickShip options make Terra a single point of contact for cleanroom builders and contractors, especially when tight project deadlines require ready-to-ship products.

- Architects & Builders Selection

- Cleanrooms | Doors | Windows | Pass-Throughs | Fan Filter Units

- UL-Listed Cleanroom Control Systems

- Cleanroom Wall & Ceiling Grid Conversion Packages

- Terra Custom Cleanroom Designer

Terra's Partner Network

It must be recognized that collaboration sets the foundation for every successful cleanroom build, Terra leverages one of the market's deepest networks of experts and to deliver comprehensive solutions. This collective approach ensures that the services provided are multifaceted and adhere to the highest standards of quality and compliance. Throughout the years, Terra has commissioned a dedicated network of service providers to streamline cleanroom engineering design, architecture, construction, and system integration.

Terra's Global Vendor Network: The Terra network includes over 20 global sales regions with a wide range of global shipping options, including door-to-door international delivery. Additionally, Terra’s network of over 80 major suppliers and vendors, our project management team coordinates with project stakeholders to ensure cost savings and timely delivery of value-add products from brands like Labconco, Thermo Fisher, Metro, Eagle, Biofit, Rubbermaid, Germfree and more.

Terra Cleanroom Design & Construction Services | Get a Same Day Quote

Terra Universal offers end-to-end construction, outfitting, certification, and testing for a wide variety of controlled environments including cleanrooms, laminar flow hoods, glove box isolators, biosafety cabinets, and lab equipment.

Shop Terra Universal Online to view a wide selection of medical and surgical doors, windows, pass-throughs, filtration systems, and more.

Contact a Terra cleanroom specialist for assistance with product configuration or application compliance via web chat, email, or phone.Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731