- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Cleanroom Humidity and Temperature Control Strategies

Posted:

December 18, 2023

Categories:

Cleanrooms

This article provides an overview of Terra's cleanroom air conditioning, humidity control, and exhaust systems, showcasing a range of products designed to maintain temperature and humidity in cleanrooms and other controlled environments.

Temperature and humidity control in cleanrooms is multifaceted and crucial for attuned operation, especially when designing HVAC systems. Cleanrooms demand stringent control over environmental parameters to ensure the integrity of processes and products. Temperature and humidity directly influence the behavior of airborne particles, chemical reactions, microbial proliferation, and the performance of equipment and materials used within these environments.

Cleanroom Temperature & Humidity

Temperature and Humidity: Humidity refers to the amount of moisture (water vapor) present in the air. The capacity of air to hold moisture is temperature-dependent. Warmer air can hold more moisture than cooler air. Therefore, as temperature increases, the air's capacity to contain water vapor also increases, which is why humidity levels often feel higher on hot days.

Dew Point: The dew point is the temperature at which air must be cooled for water vapor to condense into water. This condensation occurs when the air is saturated with moisture and cannot hold any more water vapor, leading to the formation of dew. The dew point provides a direct measure of the amount of moisture in the air; a higher dew point indicates more moisture.

Interrelation: The interrelationship between temperature, humidity, and dew point is crucial for cleanroom HVAC design. For a given amount of moisture in the air (absolute humidity), as the temperature drops, the relative humidity increases. When the temperature reaches the dew point, the relative humidity becomes 100%, and condensation occurs. In practical applications, such as in HVAC system design or environmental control in cleanrooms, understanding this relationship is essential for controlling excessive trace moisture levels that contribute to mold growth, corrosion, or product contamination.

Set Point Controls: Set point control in the context of cleanrooms refers to the process of establishing and maintaining specific environmental parameters, primarily temperature and humidity, at predetermined levels or 'set points.' Importantly, if these controls are automated to achieve specific temperature or humidity setpoints via These set points are crucial in cleanroom environments where precise atmospheric conditions are required for various sensitive processes, such as semiconductor manufacturing, pharmaceutical production, or biological research.

Differential Pressure Effects: Air density changes with temperature. Warmer air is less dense than cooler air. In a system where two connected environments are maintained at different temperatures, the differential pressure will be influenced by these temperature variations. Humidity, or the amount of moisture in the air, also affects air density. Moist air (higher humidity) is less dense than dry air (lower humidity) at the same temperature and pressure. Therefore, it's important to understand and discuss your differential pressure requirements early in the build process, which allows your cleanroom designer to ensure specific pressure differentials at your specified temperature and humidity setpoints.

Cleanroom Temperature & Humidity Control

Cleanroom temperature and humidity control present significant challenges, primarily due to the high rate of airflow required to achieve ISO-rated conditions. In environments that require precise maintenance of humidity and temperature levels, dynamic operational variables are difficult to manage.

Efficiency and power costs have become a central concern, as air must be continually retreated and refiltered, a process that can account for up to 70% of cleanroom operating costs. The rate at which air is exchanged in a space, especially in controlled environments like cleanrooms, will affect the BTU requirements. To address these challenges, we'll evaluate several systems that are designed to maximize HVAC efficiency with power-saving modes, smarter controls, and best-in-class efficiency.

Other variables affecting temperature and humidity in the clean room include environmental factors such as day and night temperature cycles, seasonal changes, elevation, enclosure integrity, and even heat gain from equipment or operators. Therefore, systems responsible for heating, cooling, humidifying, and dehumidifying need to be powerful, but also efficient and adaptable to changing conditions that arise inside and outside the cleanroom. The HVAC system capacity should be sufficient to ensure that the required performance is maintained during normal use by taking into consideration, for example, room leakage, duct leakage, and filter conditions. If not properly designed, unexpected fluctuations in temperature and humidity can strain the existing HVAC and humidity control systems in ways that lead to poor performance, poor efficiency, and shorter equipment lifespans.

Continue Reading: Cleanroom HVAC Design Principles - Best Practices and Common Mistakes

How to Control Humidity in Clean Room

Image: Do we have a HQ image for this

Terra designs its heating, cooling, and humidity control management systems specifically for cleanrooms. Beneficially, most traits that are essential in cleanrooms are also beneficial in any installation environment such as all UL-listed components, efficient high-performance motors, medical-grade air delivery, and high-grade materials that are designed for 24/7 operation. Before we get into the specific systems for humidity and temperature control, let's first consider some other essential precursors that will minimize variables and improve efficiency.

When designing enclosures for precise temperature and humidity control, the system performance will be heavily affected by exterior changes in the environment. To mitigate these variables, temperature control cleanrooms will require special attention to the integrity of the room or enclosure.

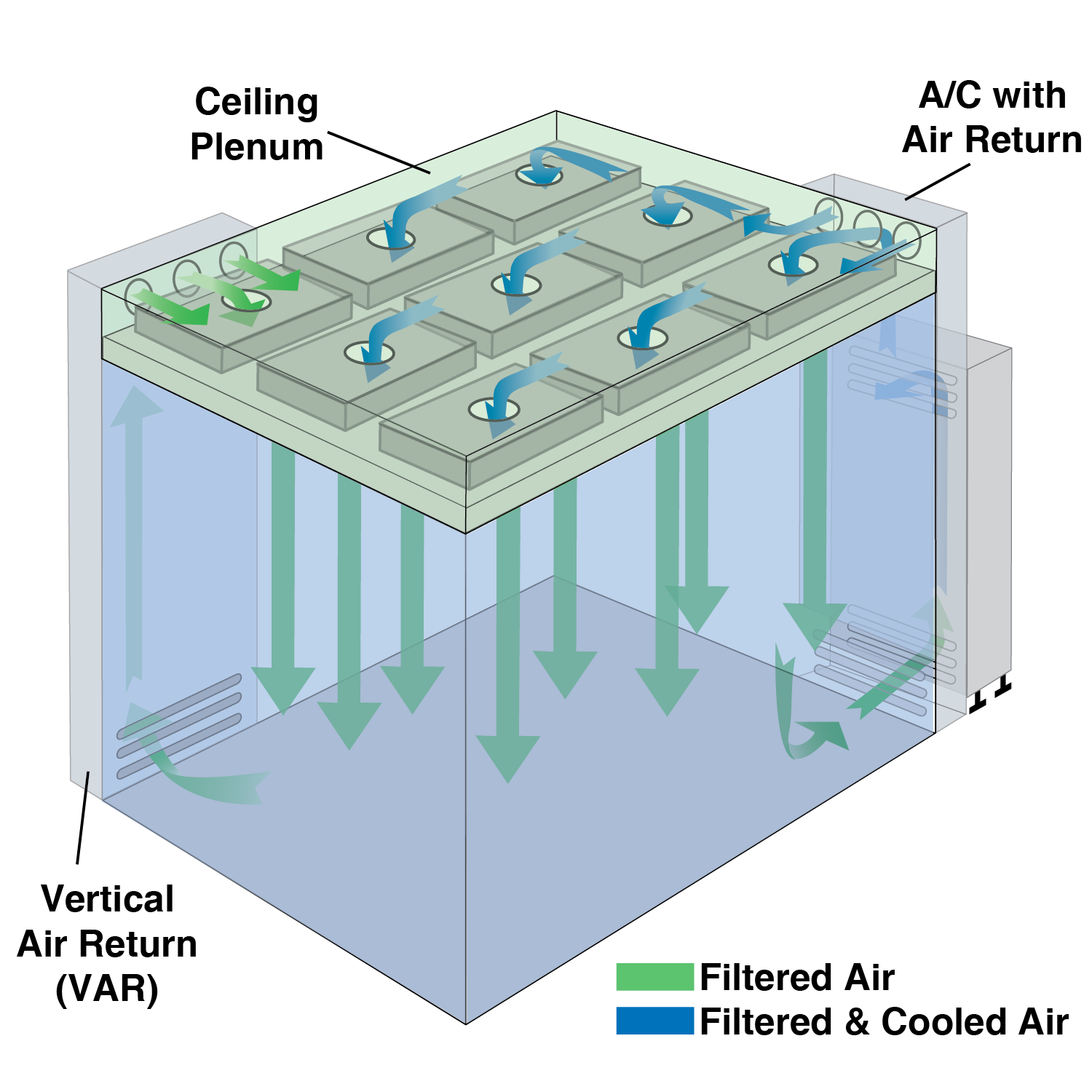

Vertical Air Returns for Cleanrooms: Terra's modular cleanrooms are often specified with internally recirculating airflow patterns, which dramatically improves heating and cooling efficiency when recirculating large volumes of pre-treated, HEPA-filtered air. Air return columns are crucial for maintaining tight temperature and humidity tolerances, dramatically reducing variability compared to single-pass, "once through cleanroom systems. Typically, these vertical air returns are integrated into comprehensive cleanroom solutions rather than offered as standalone components.

Smart® Fan Filter Power & Control Panels centralize control over assignable groups or specific targets when conducting cleanroom pressure-balancing, troubleshooting, or maintenance. These UL-Listed Smart Control Panels allow programmable fan speed adjustment, remote shutdown, and integrated displays of humidity, differential pressure, and temperature sensors.

Insulated Wall Panels: Well-insulated spaces retain heated or cooled air more efficiently, thus reducing total BTU requirements. The ease and simplicity of modular panel assembly allow for facilities to construct insulated, standalone enclosures within an existing space, thus eliminating many of the costs and difficult decisions that are associated with redesigning, retrofitting, circumventing, or reintegrating a newer, more capable HVAC system.

Cascading Airflow Design: Pressure design in controlled environments is a significant factor in controlling internal temperature and humidity values. It's important to design airflow patterns in a way that prevents the intermixing of clean, temperature controlled from outside spaces.

Controlled Entry/Exit/Transfer: Ensuring uniform temperature and humidity throughout the cleanroom becomes more challenging when production requires frequent entry and exit of people and products. Areas that are closer to air entrances and exits have significant fluctuations in temperature and humidity. When two rooms of divergent pressure share the same wall, implementing transfer systems for products and people may be necessary to maintain reliable setpoints and prevent the infusion of unconditioned air from entering areas that require maintained temperature or moisture levels.

- Airshower Entry Systems

- Pass-Through Transfer Chambers

- Airlocks

Cleanroom Air Conditioning Modules

Terra cleanroom heating and cooling systems can accommodate projects of virtually any size, scope, or complexity. Terra's standalone HVAC offerings span multiple tiers and formats. In most cases, these systems offer several different connection methods including:

- Plenum connection for cleanroom air delivery via powered fan filter units

- Rigid or flexible duct connection that routes to existing air handling systems or external exhaust

- Integration of AC modules with existing air handling units for added temperature control

If your application requires acute control over temperature or humidity setpoints, it can often be helpful to discuss your specific requirements with a Terra cleanroom specialist. Certain applications may necessitate straightforward remedies to mitigate equipment-induced heat accumulation or to maintain stable internal conditions in the face of seasonal variations and diurnal shifts. Critically, human-induced thermal output is a substantial factor; thus, the operational capacity must be evaluated to determine suitable strategies.

Wall-Mount ValuLine Air Conditioning Controls & Features

Terra's ValuLine™ Cleanroom Air Conditioning Modules allow cooling of areas up to 1,400 sq. ft with a single unit. Core functionalities include a thermostat and three-speed adjustable fan blower (low, med, high) that maintains room temperature between 60 °F – 86 °F. An integrated network card allows connection to Wi-Fi or hardwired systems and further integration with facility controls, sensors, or monitors.

ValuLine models are designed for integrated connections with a plenum system that supports air handling for up to three fan filter units (sold separately). Other unique features include filter status LEDs that indicate when fan filters require maintenance or replacement, thus greatly reducing guesswork when evaluating filter replacement cycles.

ValuLine™ Air Conditioner models are available in two formats, 23,500 BTU and 14,000 BTU. Both models include four operation modes: Energy Saver, Cool, Fan, and Dry.

Energy Saver Mode instructs the compressor and fan to cease operation upon reaching the set temperature, intermittently activating the fan every three minutes to gauge further cooling needs.

Cool Mode rapidly lowers temperature and humidity, which is adjustable via the Temp and Fan Speed buttons. When in fan mode, air circulates without engaging the compressor, offering adjustable fan speeds without requiring extra energy for temperature control.

Dry Mode is optimal for damp conditions that require humidity management without significantly cooling, automatically halting upon reaching the set temperature.

Sleep Mode allows for reduced noise and automatic shutoff, therefore reducing power usage and operational costs A Delay ON/OFF Timer enables pre-setting the unit to turn on or off within 1 hour, up to 24 hours.

User-Friendly Touch Display: Setting ambient conditions to match the needs of the cleanroom is important. The LED display and simple selection control panel, accessible from inside the cleanroom, make customization easy.

High Capacity AC / Humidity Modules for Cleanrooms

Terra's 57,000 BTU AC Conditioning Modules enable high-efficiency air conditioning with features specifically engineered for ISO-rated cleanroom environments. Boasting a cooling capacity of 57,000 BTU, it's designed to handle substantial thermal loads. The unit's compact 5-ton capacity is complemented by a barometric fresh air damper and a powder-coated steel air distribution plenum, which supports up to six Fan Filter Units (FFUs).

Air Conditioning Module with Dehumidifier and RH Control 57,000 BTU): This variant integrates dehumidification and humidity control, ensuring a consistent relative humidity (RH) level, crucial for sensitive cleanroom operations. Like its counterpart, it is suitable for ISO 7 and ISO 8 cleanrooms and offers a cooling net of 57,000 BTU, which supports up to 6 fan filter units and clean air delivery of up to 5,000 CFM.

Related: How to Calculate Room Air Change Rates & Fan Filer Coverage

Ultrasonic Humidifiers for Cleanroom Humidification

Terra's Cleanroom Space-Saving Ultrasonic Humidifier fits directly into a standard 2’x4’ (610mm x 1219mm) ceiling grid, eliminating floor clearance requirements. It uses five ultrasonic transducers to generate mist and uses only 150W, less power than conventional steam canister humidifiers. These models include a GE Smartwater Filter (GXITD) preinstalled to your unit so that you may use tap water as your supply to the Ultrasonic Humidifier. Filter replacement is conducted after 2,000 gallons or 6 months, whichever comes first. Opting to use DI water instead of tap water may extend the life of the water filter indefinitely.

Humidity Levels for Drug Stability Testing

According to the FDA, stress testing of the drug substance can help identify the likely degradation products, which can help establish the degradation pathways and the intrinsic stability of the molecule and validate the stability indicating the power of the analytical procedures used. The nature of the stress testing will depend on the individual drug substance and the type of drug product involved.

Terra's humidification modules and temperature control systems are designed for compliance in virtually any FDA-regulated facility. Ultrasonic humidifiers are designed with polypropylene materials to prevent microbial growth and stand up to aggressive cleaning agents, fumes, or vaporized disinfectants. These systems allow for clean, reliable, and maintained air delivery to support maintained testing temperatures under high humidity conditions, specifically at 75 percent relative humidity or greater. This aspect of testing underscores the necessity of incorporating humidity control modules to ensure accuracy, reliability, and compliance.

Exhaust Fans for Cleanrooms (Ventilators) For Negative Pressure Control

Terra's cleanroom exhaust fans, also referred to as exhaust ventilators, are designed to achieve negative pressure in non-hazardous cleanroom environments. These systems are built with standard dimensions for integration with dedicated exhaust handling systems. Beneficially, these systems are well suited for combining with upstream or downstream filters to capture particulate or molecular contamination.

Perhaps one of the most significant advantages of exhaust fan modules is their ability to accommodate space-constrained environments. In facilities where overhead space is limited due to existing electrical and MEP (mechanical, electrical, and plumbing) routings, installing extensive ductwork and vents is not only difficult from a logistical standpoint but also in terms of capital expenditure.

In determining the appropriate exhaust solution, one must first consider the total air capacity required for the facility. To do this, one must calculate the total cubic footage for target areas and then factor in the required air changes per hour. As a general benchmark, most negative pressure applications require a minimum of 12 air changes per hour, which involves anywhere from 2 - 3x more air handling capacity than typical HVAC conditions.

Considerations for Static Pressure in HVAC Exhaust Modules

From a performance standpoint, Terra's exhaust fan modules include a 1HP motor that is well suited for demanding air quality needs. At 0" static pressure (SP), this configuration is capable of delivering 2,418 cubic feet per minute (CFM), or 2,012 CFM at 1" SP. Static pressure is an important consideration in the context of air handling and HVAC systems, which refers to the resistance to airflow in a system. Higher static pressure increases the amount of energy required to move air through ducts or other components, therefore reducing air delivery capacity as pressure increases. Static pressure is too high may incur performance losses, or cause overstress on existing systems that are already underpowered.

Therefore, the major advantage of a standalone exhaust module is that it can be calibrated and ducted independently from existing systems, which can prevent issues with inefficient airflow or strain on facility-wide systems. Similarly, these systems allow for direct exhaust to an outdoor environment, which ensures short duct paths and easier calibration of minimum static pressure. Static pressure that is too low can mean that there isn't enough air being pushed through the system, which leads to inefficient heating or cooling and poor performance.

Terra's exhaust fans are configurable for several contamination control modes under negative pressure including fume handling, bioaersol containment, and exposure mitigation. For assistance with configuring a fume or exhaust handling system in your facility, contact a Terra Universal specialist.

Cleanroom Dehumidification Modules

Cleanroom dehumidification modules use a desiccant material to capture moisture in the air stream, which allows for lower relative humidity levels in controlled environments. Terra models feature horizontal beds with regenerating silica gel desiccant to produce dry airflow between 50 and 300 CFM, depending on the specific model.

High to Low: Humidity Setpoints In Cleanroom & Manufacturing Sectors

In the electronics industry, relative humidity ranges between 20% - 40%, which prevents damage to chips, circuit boards, and other electronic components as a result of trace moisture. As temperature increases, air can hold a greater amount of water vapor, leading to a decrease in relative humidity (assuming no change in absolute humidity). Conversely, a reduction in temperature diminishes the capacity of air to hold moisture, thus resulting in a relative increase in humidity levels. Maintaining precise temperate controls with heating and cooling systems helps to alleviate the associated impacts of climatic drift.

Automotive & EV Battery Cleanroom Humidity Requirements

Automotive and battery cell manufacturers may require reliable RH values of 20 - 30%, which supports more sensitive microenvironments to minimize the presence of moisture in the air. In critical areas that host hygroscopic materials or substances that are reactive with water, RH may require sub 1% humidity values. sensitive areas, particularly those that handle lithium battery components,

Terra offers several different enclosure configurations that can support virtually any testing requirement including explosion-proof, cold rooms, dry rooms, walk-in chambers, and burn-in chambers that are used in product evaluation and testing for both large-scale and small-scale environments.

View: Compare Specialty Climate Control Rooms

Environmental Monitoring & Test Equipment for Cleanroom Humidity & Temperature

Terra offers a broad selection of measurement and test equipment for temperature and humidity control systems.

SensoScientific® Monitoring System: Ideal for ISO-rated cleanrooms, this system offers precise ambient temperature and humidity monitoring, cloud support, and simple integration of various sensors and probes that collect data from within the environment.

Data Loggers for Relative Humidity/Temperature: Efficiently records and stores large volumes of humidity and temperature data, with easy download capabilities to Excel™ for comprehensive environmental tracking.

Temperature/Relative Humidity Meters: Versatile and portable, this meter calculates various humidity-related parameters and is ideal for spot-checking in diverse applications, enhanced by its multilingual interface.

Psychrometer for Humidity & Temperature: A convenient handheld tool for accurate humidity and temperature measurements, featuring dew point calculation, memory functions, and an automatic turn-off feature for energy efficiency.

Chart Recorders are designed to accurately record and track environmental conditions, specifically temperature, humidity, and dew point. It features a compact and rugged design, suitable for various settings. The recorder allows users to select scale ranges and recording durations (1, 7, or 31 days) through its user-selectable microprocessor.

Need Help with Product Configuration?

Shop Terra Universal products online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra sales specialist via phone, webchat, or email for help with configuration, large purchases, and application expertise.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731