- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Centrifugation is one of the most widely used laboratory techniques for the separation of materials in the fields of biochemistry, molecular biology, medicine, food sciences and industry. It’s all about gravity and mass: particles in a heterogeneous solution will, given enough time, separate based on their size and density. Smaller, less-dense particles may also migrate down, but not always; some particles will never settle, but remain suspended in solution. Centrifuges force this process along much more quickly and efficiently. Its uses have proven to be so powerful and wide-spread across the sciences that centrifuges have been a common piece of laboratory equipment since the late 19th century.

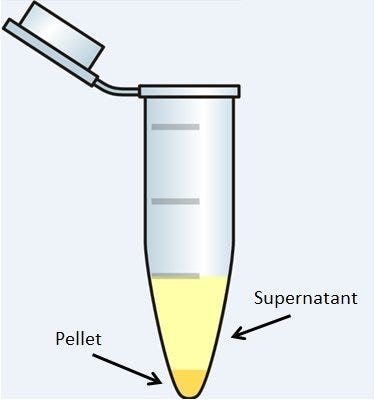

Centrifuge tube, showing separation.

Centrifugation utilizes the application of centripetal force to drive the separation of a heterogeneous solution into supernatant and pellet. The modern centrifuge amplifies the force of gravity by spinning solutions at a high rate of speed to increase the rate of sedimentation. During this process, materials with a high particle density will sediment towards the axis of centrifugation (down the tube), while materials with a lower particle density will sediment away from the axis of centrifugation. For example, bacterial cells in suspension have a high particle density and will tend to settle to the bottom.

A process that would normally take hours or days under the force of normal gravity (1 g) can be shortened to only minutes when a force of 10,000 g is applied with a relatively inexpensive and easy-to-use piece of equipment. It is common to hear about revolutions-per-minute (RPM); the more times it turns, the faster the speed and greater the energy being applied. Relative centrifugal force (RCF) is another way of expressing the gravitational force (g-force), or the turning of the rotor. Thus, it’s clear to see how this simple device can allow researchers to easily separate tissues, cells, organelles, and macromolecules for further investigation.

Swing-Bucket centrifuge rotor from Thermo Scientific.

The centrifuge is composed of a rotor, which is used to house the tubes where separation occurs. There are two main types of centrifuge rotors: fixed-angle or swinging bucket. Fixed-angle rotors hold tubes at a stable angle (typically 45°) relative to the axis of rotation. A swinging-bucket rotor swings out when centripetal force is applied and holds the cells at an approximate 90° angle relative to the angle of rotation. Recall that more dense materials will separate towards the angle of the centripetal force. Therefore in swinging-bucket rotors, the pelleted material will form at the bottom of the conical centrifuge tube, while tubes processed in a fixed-angle rotor will form sedimentation on the side. This could be problematic if the solids get caught in the angle of the tube.

Thermo Scientific Fixed-Angle centrifuge rotor.

All things being equal, the fact that swinging-bucket rotors offer a superior sedimentation location makes them the obvious choice for centrifuging samples; however, fixed-angle rotors offer valuable features that often make them a more desirable choice. What are they? First, due to their simple and efficient tube spacing, fixed-angle rotors can hold a greater quantity of tubes compared to its swinging-bucket counterpart, making it more practical for high-throughput applications. Next, as a result of the rigid design of the metal alloy material, fixed rotors can withstand much higher gravitational forces, which is necessary when separating biological macromolecules such as RNA, DNA and protein.

Regardless of your application and rotor design, centrifugation is a powerful tool for separation of micro- and macro-molecules in solutions. Centrifuges of all types and sizes are used every day for biological analysis in forensic investigations (such as separating and studying blood and urine), pharmaceutical development (characterizing macromolecules), food purity (like removing fat from milk), and wastewater management (separating “sludge” and heavy metals from water).

Centrifuges offered by Laboratory-Equipment.com.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Call (714) 459-0731