- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

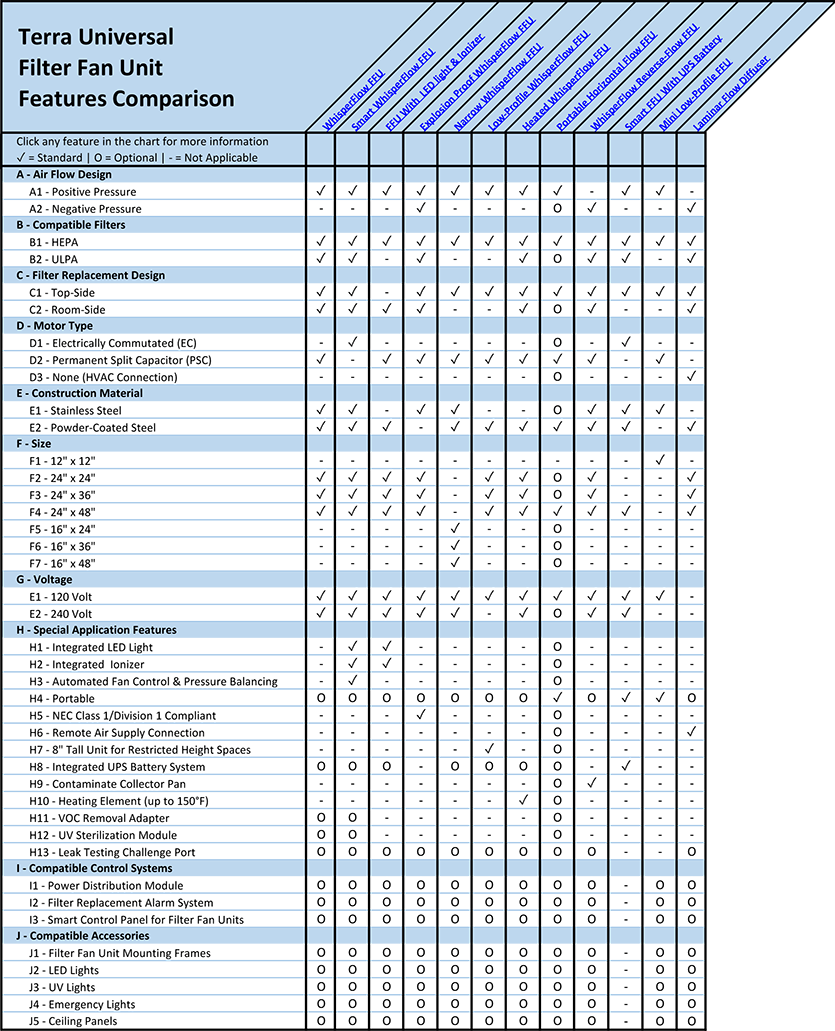

Cleanroom Fan Filter Features Comparison

Posted:

July 19, 2021

A - Fan Filter Air Flow Design

(back to chart)

A1 - Positive Pressure Fan Filter Units

Terra's positive pressure fan filter units include HEPA fan blowers capable of ISO Class 3 - ISO Class 8 air quality conditions. ULPA filtration units are available for the most sensitive ISO 3 - ISO 5 product applications including pharmaceutical compounding, semiconductor wafer processing, sterile packaging, and micro/nanofabrication.

A2 - Negative Pressure Fan Filter Units

Reverse-flow impeller FFUs capture particles generated in localized cleanroom spaces to minimize contamination and ensure operator protection.

Terra's negative pressure fan filters provide capable and safe production environments for reducing operator hazards in increased-risk applications such as USP 800 compounding, infectious disease research, and chemically intensive processes that require volatile chemical handling.

B - Compatible Cleanroom Fan Filters

(back to chart)

B1 - HEPA Fan Filter Units

HEPA filters remove 99.97% of airborne particles greater than or equal to 0.3μm in diameter. HEPA fan filter units are common for contamination and air quality control for industries including pharmaceuticals, medical devices, OEM assembly, healthcare, life sciences, infection control, and laboratory or testing environments.

B2 - ULPA Fan Filter Units

ULPA filters are 99.999% efficient for monodispersed particles 0.12 μm in diameter or larger. ULPA filtration offers additional particulate control for ultra-sensitive hardware including display panels, wafer chips, microoptics, satellite imaging, and nanotechnology applications.

C - Filter Replacement Design

(back to chart)

C1 - Top-Side Fan Filter Units

Top-side replaceable filters are a standard package available with Terra fan filter units. Standard FFUs offer a lower cost option and are ideal for small-scale and less critical cleanroom operations. To change the filter, the unit must be entirely pulled out of the ceiling bay. Climbing up to remove the bulky FFU can be difficult, dirty, and hazardous. The procedure may require tall ladders, multiple people, personal protective equipment, and perhaps worst of all, shutting down the cleanroom.

C2 - Room-Side Fan Filter Units (RSR)

Room Side Replaceable (RSR) fan filters eliminate the need for access to a roof or overhead ceiling space when conducting fan filter maintenance and replacement. Breaching the cleanroom ceiling is not required when installing or replacing RSR fan filter units or their HEPA filter media. The filter media is easily accessible from inside the cleanroom, an ideal trait for facilities with restricted ceiling heights or for pharmaceutical operations that require more frequent HEPA filter replacements.

D - Fan Filter Motor Type

(back to chart)

D1 - Electronically Commutated (EC)

Terra's Smart® electronically commutated (EC) brushless motors include an internal microprocessor and MODBUS® networking control card. Easily integrate your fan filter with a building management system, control panel, or additional air pressure, airflow, and particle count sensors.

D2 - Permanent Split Capacitor (PSC)

PSC motors are priced for affordability but are significantly less energy-efficient than their EC counterparts.

Read more: FFU Costs for an Energy-Efficient Cleanroom

D3 - None (HVAC Connection)

Motorless fan filter units include ducted collars for connection to an existing air handling unit or pre-conditioned air supply. Unlike actively powered FFU motors, motorless designs do not require electrical connections. The lightweight assembly makes for easy ceiling grid installation and includes the same baffles, diffusers, and HEPA media for smooth, quiet, and uniform air delivery.

E - Construction Material

(back to chart)

E1 - Stainless Steel Fan Filter Units

Stainless steel is a gold standard among cleanroom construction materials. Easy cleaning, favorable heat properties, and chemical resistance make stainless steel an ideal choice for biopharmaceutical and semiconductor environments. The smooth surface is easy to wipe down, resists biofilm buildup, and will not off-gas.

E2 - Powder-Coated Steel Fan Filter Units

Powder-coated steel is an economical choice that also provides favorable heat and chemical resistance for most applications. Terra’s signature white powder coat finish provides a high quality, durable barrier to protect against corrosion, plus a clean and attractive aesthetic. The advanced heat-fuse formulation exceeds ASTM and ISO paint standards to resist chipping, scratching, fading, and wearing.

F - Fan Filter Size

(back to chart)

Terra provides several fan filter unit sizes and styles to accommodate your existing ceiling grid. Each configuration is available with optional duct collars and optional 1/4 inch (6 mm) eyebolts in all (4) corners for hangwire support (order eye bolt package separately).

F1 - 24" x 24" Fan Filter Units

2' x 2' fan filters provide moderate flow rates and accommodate standard square ceiling grid installations. Lightweight (25 lbs) provides easier installation.

Approximate Weight: 25 LBS

F2 - 24" x 36" Fan Filter Units

2' x 3' fan filter units are intended for use with supported ceilings that can safely bear the weight of a fan filter unit or light panels to be installed. HEPA/ULPA packages provide a uniform flow of microfiltered air to meet cleanliness standards down to Class 10 (ISO 4).

Approximate Weight: 53 LBS

F3 - 24" x 48" Fan Filter Units

2' X 4' fan filter units accommodate standard cleanroom ceiling grid and laminar flow hood configurations and are intended for use with supported ceilings that can safely bear the weight of a fan filter unit or light panels to be installed. HEPA/ULPA filters provide a uniform flow of microfiltered air to meet cleanliness standards down to Class 10 (ISO 4). Optional with 1/4 inch (6 mm) eyebolts in all (4) corners for hangwire support (order eye bolt package separately).

Approximate Weight: 71 LBS.

F4 - 16" x 24" Fan Filter Units

Narrow fan filter units fit in a space-saving enclosure for a smaller footprint. Optional with 1/4 inch (6 mm) eyebolts in all (4) corners for hangwire support (order eye bolt package separately)

F5 - 16" x 36" Fan Filter Units

Narrow fan filter units provide a space-saving enclosure for a smaller footprint. Optional with 1/4 inch (6 mm) eyebolts in all (4) corners for hangwire support (order eye bolt package separately)

Approximate Weight: 50 Lbs

F6 - 16" x 48" Fan Filter Units

Narrow fan filter units fit in a space-saving enclosure for a smaller footprint. Optional with 1/4 inch (6 mm) eyebolts in all (4) corners for hangwire support (order eye bolt package separately)

Approximate Weight: 50 Lbs

G - Fan Filter Voltage

(back to chart)

G1 - 120 Volt Fan Filter Units

Standard 120 volt connection is suitable for standard residential power outlets in the US. Ideal for powering mobile-mounted fan filter units. Black and red wires are connected to the lower terminal. A along with a yellow jumper cable.

G2 - 240 Volt Fan Filter Units

240V connections require less current (amperage) and smaller conductors than appliances designed to operate at 120V. Ideal for fan filter units with optional heating, cooling, ionization, or UV lighting modules.

H - Special Fan Filter Application Features

(back to chart)

H1 - Integrated LED Fan Filter Light

Fan filter units with integrated LED lights enable 100% coverage of a ceiling grid with fan units while also providing adequate lighting. 100% integration of the ceiling grid is typically reserved for high-performance environments with ISO Class 5 ratings or cleaner.

H2 - Integrated Fan Filter Ionizer

Integrated ionizers provide a continuous stream of static-neutralizing ions to protect sensitive materials against ESD. Built-in ionizers enhance cleanliness by neutralizing charges that attract and hold particles on walls, tabletops, and other surfaces. Ionizers are known for being maintenance burdens that require frequent calibration. Unlike ionization technologies offered by Terra competitors, Terra systems require no calibration and automatically maintain a balance of ± 50 volts.

H3 - Automated Fan Filter Control & Pressure Balancing

Terra's Smart® Fan Filter Units paired with Smart® Cleanroom Control Panels adjust the fan speed up or down to “dial in” the proper air velocity, internal pressure, and air change rate. Variable fan filter control lets you balance FFU performance from one clean zone to another, ensuring that you maintain the pressure gradients and air change rates required. As the filters mature and air velocity decreases, the system lets you perform small speed adjustments that keep your cleanroom performing to spec.

H4 - Portable Fan Filter Units

ValuLine portable fan filter units are mobile, self-contained, hospital-grade HEPA purifiers mounted on a rolling stand. The small footprint, rolling stand, and plug-and-play operation allow easy transfer between rooms or departments.

H5 - NEC Class 1/Division 1 Compliant

Terra's explosion-proof fan filter units isolate fumes and vapor from any spark, hot surface, or friction-inducing electrical components.

Explosion-proof LED lights are available with a T5 temperature rating and are designed for low-profile pendant mounting to make maximum use of available space.

Division I environments contain ignitable concentrations of hazards under normal operating conditions and/or where the hazard is caused by frequent maintenance or repair work or frequent equipment failure.

Class I locations are those in which flammable vapor and gases may be present.

H6 - Remote Air Supply Connection

Terra's Laminar Flow Diffusers with HEPA Filters include a 12"-diameter collar for air supply connection for connecting the fan filter assembly to a remote air source. Threaded inserts in the top corners accommodate eyebolts to facilitate installation using suspended guy wires (order eyebolt packages separately).

H7 - 8" Tall Unit for Restricted Height Spaces

Low-profile 8"H fan filter units are ideal for cleanrooms installed within restricted height areas.

H8 - Integrated UPS Battery System

An Uninterruptible Power Supply (UPS) is a backup system that provides battery power to fan filter units when utility power is unavailable. In the event of a power outage, the UPS immediately activates without interruption and recharges when power is restored.

Smart® EC Fan Filter Units with UPS keep your FFU running long enough to safely store away contamination-sensitive materials, shut down work-in-progress, and/or switch to a backup power generator. Handy and convenient, the Uninterruptible Power Supply (UPS) provides power when and where you need it. The included external 24V battery pack offers extended battery runtime when used with the main tower UPS system.

H9 - Cleanroom Fan Filter Contaminant Collector Pan

A fan filter collector pan accumulates dust particles that dislodge from the HEPA filter, preventing contaminants from re-entering the cleanroom. Terra's collector pan integrates with bag-in/bag-out (BIBO) systems and is easily removed for cleaning or maintenance.

Bag-in/Bag-out (BIBO) modules are optional accessories for applications involving toxic fumes or biohazards. BIBO modules seamlessly integrate with the filter media system for safe filter disposal and replacement from the inside of the room for contact-free removal of filters with potentially hazardous airborne contaminants.

H10 - Fan Filter Heating Element (up to 150°F)

Heated fan filter units provide high-temperature air of up to 150 degrees Fahrenheit.

H11 - Fan Filter VOC Removal Adapter

Volatile Organic Compound (VOC) Removal Adapters require an adapter module for each FFU. The package includes an adapter housing, one charcoal pre-filter, two sanitizing modules, and one PCO panel and must be ordered together with a Terra WhisperFlow FFU.

Photo-Catalytic Oxidation Panels (PCO) remove volatile organic compounds (VOCs) remaining in the air stream after they pass the carbon filter. The PCO panel is highly efficient at vapor removal, yet imposes no restrictions on airspeed, allowing the Fan/Filter Module to maintain airspeed consistent with ISO cleanliness requirements (typically 80-100 feet/minute).

The carbon pre-filter removes volatile organic compounds (VOCs) to ensure a safe, clean processing environment. The pre-filter also helps compensate for VOC spikes that might occur during certain operations.

H12 - Fan Filter UV Sterilization Module

Terra Fan Filters Units with integrated UVC decontamination modules provide additional protection against bioaerosols and pathogenic organisms. UV-C lamps may not produce an entirely sterile surface, but they can maintain consistently low microbial loads throughout a wide range of operations and eliminate bioburden spikes that could necessitate extensive testing and decontamination measures. UV Sterilization modules are not compatible with the following FFU designs: Narrow, Explosion Proof, or Reverse Flow.

H13 - Cleanroom Leak Testing Challenge Port

Fan filter units with challenge ports provide a simple and efficient mechanism for conducting localized leak tests of each filter. Terra fan filter units are leak tested before delivery in accordance with IEST and UL 900 standards. For critical applications, the USP <797> framework requires that fan filter units undergo leak testing during initial installation, and semiannually throughout the life of the filter. Filter testing is also common in operating rooms, surgical suites, and CGMP facilities.

Leak testing requires the injection of an aerosol upstream of the filter. Fan filters with challenge ports allow for rapid and individual testing of each fan filter unit without requiring the introduction of test aerosols to the entire HVAC system. Challenge port testing is a more reliable method of ensuring that a test aerosol is uniformly applied and presents fewer variables.

I - Compatible Control Systems

(back to chart)

I1 - Cleanroom Fan Filter Power Distribution Module

Terra’s Power Distribution Modules (PDMs) use 3-pin or 4-pin quick connect fittings to power all FFUs and lights, regardless of the cleanroom size. The expertise of a licensed electrician is only needed to connect the main voltage to the Primary, Secondary, and Booster PDM modules; lights and fan filters are installed via quick-connect fittings without requiring hard wiring. The PDM modules must be wired to a dedicated 35A fused 120V circuit or a 30A fused 240V circuit to allow a quick fit connection of up to 5 light and 5 FFU connections per module.

I2 - Cleanroom Fan Filter Replacement Alarm System

Fan Filter Replacement Alarms provide a reliable, quantitative method for determining when HEPA fan filter media requires replacement. Automatic replacement alerts avoid costly and unexpected operational interruptions while also maximizing the working life of the fan filters.

I3 - Smart Control Panel for Filter Fan Units

Standard Control Panels provide central control and connection of lights and filters. An optional Night Service Switch drops all Fan/Filter Units (FFUs) into a low-energy mode for nights and weekends.

Smart® Control Panels connect to EC FFUs for individual or grouped fan control and remote monitoring of room differential pressure, particle counts, temperature, and humidity. The robust system offers advanced control for up to 200 fan filter units and 16 independently controlled rooms.

An upgraded Smart® Control System allows additional environmental sensors and FFU control to meet critical performance/monitoring requirements including programmable fan speed adjustment for energy savings, performance enhancement, or remote shutdown. Easily connect additional sensors to display humidity, differential pressure, and temperature data.

J - Compatible Accessories

(back to chart)

J1 - Cleanroom Fan Filter Unit Mounting Frames

Stainless steel mounting frames allow fan filter units or light panels to be installed in drywall or other hard ceilings without a ceiling grid.

J2 - Cleanroom LED Lights

Cleanroom LED lights are energy-efficient, produce low heat, carry long life spans, and are compatible with ISO class 3 spaces.

J3 - Cleanroom UV Lights

Although UV-C lamps may not produce an entirely sterile surface, they can maintain consistently low microbial loads throughout a wide range of operations and eliminate bioburden spikes that could necessitate extensive testing and decontamination measures.

J4 - Cleanroom Emergency Lights

Cleanroom LED Light Panels with Built-In Emergency Batteries allow for temporary backup lighting during a power outage. When receiving power, the light operates normally and charges the emergency battery. A UL recognized emergency driver allows the LED fixture to be used for normal and emergency operation. The LED light has a red/green indicator to inform employees after power has returned and the cleanroom is safe to re-enter.

J5 - Cleanroom Ceiling Panels

Cleanroom ceiling panels cover ceiling bays not occupied by fans or lights. These panels are available in several materials that support frequent cleaning and will not absorb water or crumble like conventional gypsum ceiling panels. Chemically resistant polypropylene panels are preferable for use with most chemical solvents and acids. Stainless steel panels are typical for pharmaceutical and USP-regulated environments that require aggressive chemical sterilants or vapor treatments during cleaning regimens. Vinyl-covered gypsum is cost-effective and fire-rated but does not offer the wider chemical compatibility of other materials. All Terra ceiling panels are cleanroom appropriate for ISO Classes 5 to 8 and Federal Standard 209 Classes 100 to 100,000.

Terra Universal is the leading US manufacturer of critical environment equipment with a diversified product line including cleanrooms, desiccators, hoods, glove boxes, cleanroom furnishings and similar equipment.

Shop online to view a wide selection of fan filtration systems, cleanroom components, and controlled environment enclosures.

Contact a Terra cleanroom specialist for assistance with product configuration or application compliance via web chat, email, or phone.

Shop Filtration Systems and Components

Cleanrooms and Containment Enclosures

Browse by Industries and Applications

Sterile and Non-Sterile Compounding

Semiconductor Manufacturing Equipment

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731