Desiccant dehumidifiers are essential for maintaining accuracy and stability within a clean room. The accuracy and stability of humidity levels are critical, which is why desiccant dehumidifiers are preferred due to their ability to control humidity levels with a high accuracy of +/-2% RH.

Also referred to as desiccant dryers, Terra offers several dehumidifier models from Condair to support industrial or cleanroom environments with extremely low relative humidity levels of 10 - 20% RH. These high-performance dehumidification systems have several unique features and attributes when compared to typical residential dehumidifiers:

Condair DA Desiccant Dehumidifier Features

Energy and Efficiency: Condair DA Desiccant Dehumidifiers are standardized with all UL approved components, and boast energy-efficient operation to lower operating costs.

Large Diameter Desiccant Rotors offer low pressure drop and more efficient absorption of water molecules. The rotors are vertically mounted providing greater mechanical stability. The desiccant rotor system is more effective at low temperatures where traditional units struggle. Importantly, the desiccant rotor material is nonflammable and silicone-free to minimize particulate generation and prevent fire hazards.

Double-Wall Housing: The sturdy double-wall housing construction ensures superior durability and minimizes thermal transfer, reducing operating costs and optimizing performance in harsh environments.

Flexible Configuration: Options include integration with pre-cooling or post-cooling batteries, heat exchangers, and condensation modules for streamlined integration with existing facility systems.

Continue to: Understanding Conductive vs Insulated Properties for ESD Control

A - Cleanroom Dehumidifier Drying Capacity (60% RH)

(back to chart)

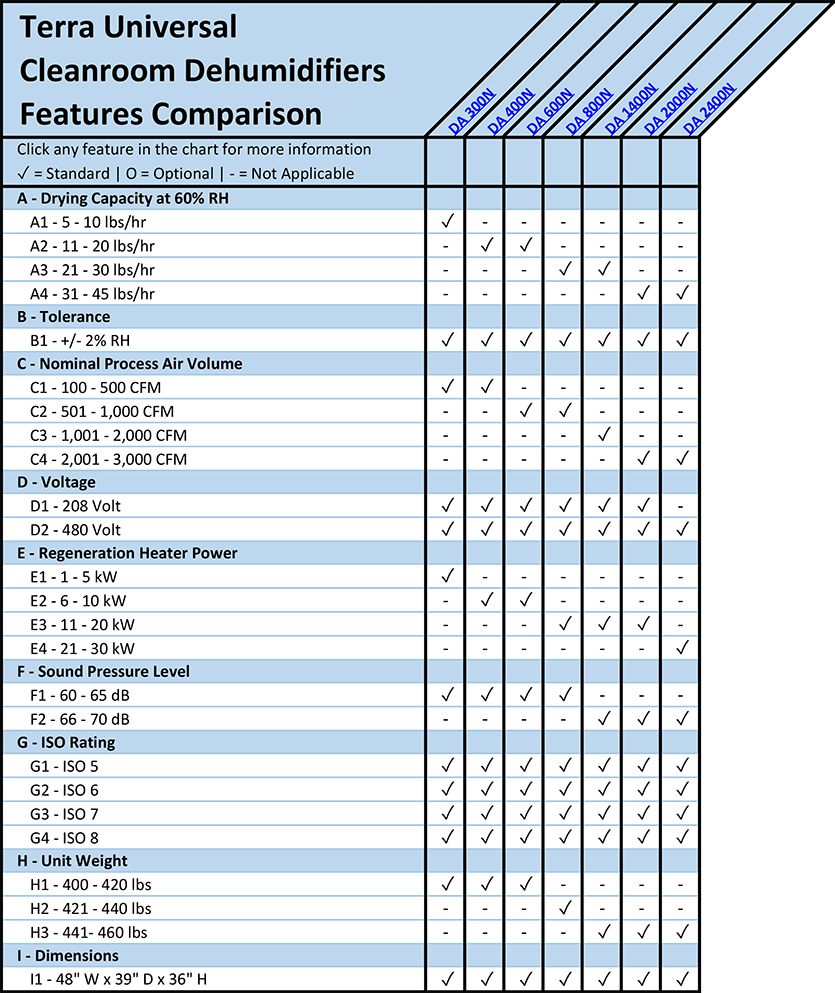

The dehumidifier comparison chart below delineates the attributes and specifications of various cleanroom dehumidifier models, specifically Condair's DA 300N, DA 400N, DA 600N, DA 800N, DA 1400N, DA 2000N, and DA 2400N.

| Technical Data | Units | DA 300N | DA 400N | DA 600N | DA 800N | DA 1400N | DA 2000N | DA 2400N |

|---|---|---|---|---|---|---|---|---|

| Drying capacity at 68° F -60% RH | lbs/h | 7.3 | 11.2 | 15.6 | 22 | 29.7 | 31.9 | 44.1 |

| Nominal process air volume | CFM | 294 | 412 | 589 | 824 | 1413 | 2001 | 2354 |

| Nominal regeneration air volume | CFM | 88 | 129 | 206 | 235 | 294 | 323 | 500 |

| Ext. compression - process air | in. H20 | 1.2 | 0.9 | 1.2 | 0.8 | 1.2 | 1.2 | 0.8 |

| Ext. compression - regeneration air | in. H20 | 1.2 | 1.0 | 0.8 | 1.2 | 1 | 0.8 | 0.8 |

| Regeneration heater power | kW | 4 | 7 | 10.2 | 13 | 17 | 18 | 23 |

| Electrical connection load | 208V | 5.8 | 8.8 | 11.9 | 14.8 | 21.6 | 22.1 | n/a |

| 480V | 7.9 | 9.6 | 12.9 | 15.6 | 20 | 23.4 | 31.4 |

A1 - 5 - 10 lbs/hr: The DA 300N model is capable of drying 7.3 lbs/hr. These systems are ideal for small cleanroom operations and general lab environments with minimal air handling requirements.

A2 - 11 - 20 lbs/hr: Both the DA 400N and DA 600N models have a drying capacity ranging from 11 - 15 lbs/hr, respectively.

A3 - 21 - 30 lbs/hr: The DA 800N and DA 1400N models are designed for a higher drying capacity, falling within the 22 - 30 lbs/hr range.

A4 - 31 - 45 lbs/hr: The most advanced models, DA 2000N and DA 2400N, offer the highest drying capacity, capable of handling 31 - 44 lbs/hr.

B - Cleanroom Dehumidifier Tolerance

(back to chart)

Typical HVAC sensors, while widely used, offer an accuracy margin of +/-4%, with potential hysteresis effects doubling this inaccuracy, cumulatively impacting control precision to about +/-7.5%. Therefore, selecting sensors with rapid response times (less than 30 seconds) is essential to ensure reliable data reporting and simplify calibration of dehumidifier control equipment.

Continue to: Cleanroom HVAC and Temperature Control Strategies

B1 - +/- 2% RH Dehumidifier Tolerance

Fluid Bed Drying: Consistent and responsive humidity control in FBD processes results in the product’s moisture content reaching the target level more rapidly and with less wastage through over or under drying. Close control steam humidifiers running on pure RO water can provide ±2%RH and increase productivity when compared to more traditional live steam humidifiers mounted on fluid bed dryers.

Stability Testing: Regulations on accelerated or long-term stability testing mostly require humidity to be controlled within a tolerance of ±5%RH. If the condition of the atmosphere falls outside this window, results are often unreliable and require retesting, which is not only expensive but also likely to delay project deadlines.

Pharmaceuticals: Maintaining precise humidity levels is crucial for many aspects of the manufacturing, processing, drying, and storage of pharmaceutical products. Since pharmaceutical products are generally hygroscopic and easily absorb moisture from the air, therefore the environment must achieve and maintain humidity control zones within +/-2% relative humidity.

FDA / GMP / GLP Compliant Facilities: Reliable moisture control is instrumental for FDA-compliant facilities with zero tolerance for mold, mildew, and opportunistic microbes. Beneficially, reliable humidity control prevents instances where environmental drift could negatively impact processes that affect potency, purity, and shelf life. To mitigate these risks and ensure optimal process performance, FDA-enforced facilities adhere to strict temperature and humidity control guidelines.

Dry Rooms and Cold Rooms for modern battery processing maintain precise humidity levels of less than 0.5% relative humidity for lithium battery manufacturing at ambient temperatures of 21°C (70°F). Achieving such low levels of humidity may require dew points that exceed -40°C for lithium batteries. For automotive hybrid battery manufacturing, these rooms support dew points as low as -70°C.

Continue to: Climate Control for EV Battery Facilities

C - Cleanroom Dehumidifier Nominal Process Air Volume

(back to chart)

C1 - 100 - 500 CFM: This air volume range is supported by models DA 300N and DA 400N, indicating their suitability for smaller cleanroom environments where moderate airflow is sufficient to maintain desired humidity levels.

C2 - 501 - 1,000 CFM: Models DA 600N and DA 800N operate within this air volume range, providing enhanced airflow for medium-sized cleanrooms, and ensuring effective humidity control over a larger area.

C3 - 1,001 - 2,000 CFM: DA 1400N models are equipped to handle substantial air volumes, making it ideal for larger cleanroom settings or areas with higher humidity loads requiring more aggressive dehumidification.

C4 - 2,001 - 3,000 CFM: Models DA 2000N and DA 2400N are designed for the highest air volume range, capable of managing extensive airflow for very large cleanrooms or industrial spaces with significant dehumidification needs.

D - Cleanroom Dehumidifier Voltage

(back to chart)

Voltage selection enhances the utility of dehumidifier deployment among a broader array of cleanroom settings. 208V systems accommodate smaller labs requiring lower voltage, while 480V systems support large-scale industrial applications that require higher voltage levels.

D1 - 208 Volt Dehumidifiers: are a common standard for light to medium industrial and commercial applications, offering a balance between energy efficiency and operational capability. Models with standard 208-volt power supplies include the DA 300N, DA 400N, DA 600N, DA 800N, DA 1400N, and DA 2000N.

D2 - 480 Volt Dehumidifiers: accommodate higher power demands including models DA 400N, DA 600N, DA 800N, DA 1400N, DA 2000N, and DA 2400N. Well suited for larger and more intensive dehumidification tasks.

E - Cleanroom Dehumidifier Regeneration Heater Power

(back to chart)

E1 - 1 - 5 kW: DA 300N models are categorized for moderate dehumidification needs with lower energy consumption, making them ideal for energy-efficient operations.

E2 - 6 - 10 kW: DA 400N and DA 600N models provide a balanced approach to dehumidification with manageable energy usage, suitable for a variety of settings.

E3 - 11 - 20 kW: Models DA 800N, DA 1400N, and DA 2000N are in this category, equipped for more demanding environments, ensuring effective desiccant regeneration in larger or more humid spaces.

E4 - 21 - 30 kW: DA 2400N models fall into the highest power requirement category, necessary for tackling challenging dehumidification tasks in excessively humid or large-scale environments.

F - Cleanroom Dehumidifier Sound Pressure Level

(back to chart)

F1 - 60 - 65 dB: This sound pressure level range, indicative of relatively low operational noise, is featured in models DA 300N, DA 400N, DA 600N, DA 800N, ensuring their suitability for environments where minimal noise disturbance is crucial, such as laboratories or hospitals.

F2 - 66 - 70 dB: Models DA 1400N, DA 2000N, and DA 2400N fall within this higher sound pressure level category, reflecting their capacity for more robust dehumidification tasks, which may be acceptable in industrial settings or areas where noise levels are less of a concern.