- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Cost-Effective Environmental Monitoring for CGMP and GLP Requirements

Posted:

July 30, 2021

Categories:

Cleanrooms

Cleanroom monitoring systems are quickly becoming a feature expected for all modular cleanrooms, especially given the cGMP and GLP requirements for environmental reporting.

Not every facility requires arrays of sensors for temperature, particulate, humidity, and pressure differential. The cost of a monitoring system is derived from several factors including the number and type of sensors, sampling rate, instrument sensitivity, and any value-added features such as WIFI, alarms, and automation of feedback controls. Determining the best option requires balancing a facility's needs today with the possibility of growth and expansion years down the line.

SensoScientific Cleanroom Monitoring Packages

Senso Scientific’s cleanroom monitoring systems include four different configurations for logging and displaying cleanroom conditions. Each package is configurable with your choice of sensors and retrofittable for later upgrades.

- Room pressure only

- Room temperature and humidity

- Room temperature, humidity, high speed, and pressure

- Refrigerator temperature (for cold storage spaces)

Beneficially, you'll still get the same smart-enabled features such as alarms and WIFI monitoring that are typically reserved for more advanced (and more expensive) systems. Collected data is automatically uploaded to a validated Cloud platform – the user can set up notifications, alerts, and reports directly from the Cloud portal.

The SensoScientific Cloud portal uses bank-grade security for reliable access to data collected and stored by the sensors anywhere and anytime with OTA technology.

Cleanroom managers get access to comprehensive reporting:

- Monthly, weekly, and daily reports

- Graphical temperature trend analysis

- Automatic temperature reports by email

- Alert and corrective action history

Given the low cost, ease of installation, and retrofitting capabilities, Terra recommends these systems for cleanroom projects that don't need state-of-the-art control systems, yet still require a dedicated environmental monitoring system. Although SensoScientific systems do not directly control the operation of a cleanroom, they do offer a cost-effective, configurable option for displaying and logging temperature, humidity, and room pressure.

Cleanroom Pressure Monitors

SensoScientific differential pressure monitoring systems provide\ early warning of changing air pressure conditions that would otherwise impact the regulatory compliance of a sterile work environment.

The differential pressure sensors actively measure bi-directional and unidirectional pressure between a positive or negative buffer room and the ante-room. The wireless differential pressure sensors use Wi-Fi to send information to the cloud.

The latest OTA Series differential pressure sensors are equipped with compact pressure probes, small enough to place anywhere and powerful enough to meet ISO/IEC regulatory parameters. These sensors enter a low-power mode between readings, ensuring accuracy, reliability, and product longevity. Data can be viewed from the device’s visual display or accessed through the online portal.

Cleanroom Temperature Sensors

Senso Scientific also offers a streamlined remote temperature monitoring system with the integrity to meet the stringent needs of regulatory bodies such as the FDA, USP, AABB, CAP and joint commission, NIST, and more. In fact, these are the same sensors selected by the FDA to monitor their own laboratory.

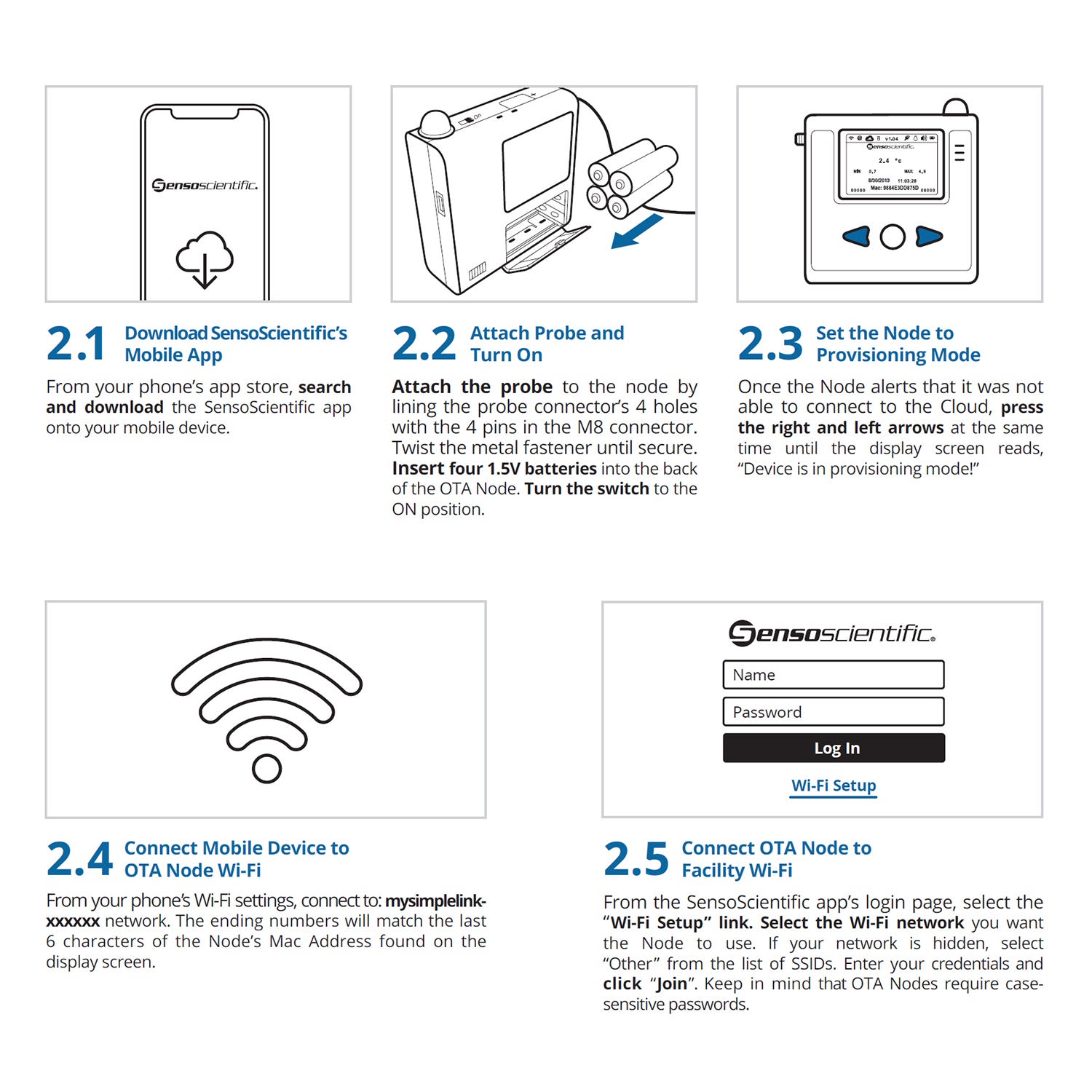

This series of nodes boasts over-the-air upgrade (OTA) capabilities and enables the devices to remotely upgrade without the need to be manually serviced.

Alarms and Alerts

The SensoScientific system is ideal for clinical trials and other research settings as you can safeguard against the loss of precious research specimens and pharmaceuticals through advanced notifications via phone, email, or text.

For example, a temperature monitoring system ensures that cold or ambient storage retains the ideal climate within a user-assigned temperature setpoint. Typically, the cold storage temperature must maintain a specific target range for minimum and maximum temperature.

For facilities handling vaccines, the Moderna COVID-19 vaccine requires freezer temperatures between -25°C and -15°C (-13°F and 5°F). The Pfizer COVID-19 vaccine requires storage in an ultra-cold freezer between -80°C and -60°C (-112°F and -76°F).

Human error and left-open doors are the most common precursors of cold storage failures. However, these mistakes are easily avoided by incorporating an active freezer monitoring system that can alert the operator to environmental drift. Door ajar sensors are available with audible alerts or mobile notifications that inform both the operator and the facility manager based on the predetermined setpoint.

SensoScientific alarms are visual and audible. Additional alerts can be provided through a variety of methods such as SMS, text message, voice, pager, cell phone, fax, and e-mail. The information is recorded to a database and time-stamped, and therefore cannot be altered through the user interface.

Installation and Retrofitting

WIFI monitoring systems are ideal for scenarios where it would be expensive, inconvenient, or technically difficult to install a hardwired system. Typically, cleanroom monitoring sensors require a licensed electrician and removal of the ceiling grid to install power and data collection. Therefore, each sensor needs to be wired and installed by hand, then conduit or coving is installed over the wires to provide easy cleaning and prevent particle retention.

SensoScientific Wi-Fi transmitters include high-speed wireless modules capable of collecting, storing, and transmitting data wirelessly over a standard Wi-Fi-enabled network. Each transmitter monitors against preset conditions that are defined by the user.

These systems require less maintenance and are more cost-effective than hardwired alternatives. The devices remotely upgrade without the need to be manually serviced.

Centralized Environmental Monitoring

SensoScientific can monitor all of your sensitive equipment and conditions, such as:

- Reach-In Refrigerators

- Ultra-Low -80°C Freezers

- Walk-in Refrigerator

- Heat Blocks

- Slide Warmers

- Lab Freezers

- Water Baths

- Water Leaks or Flooding

- Power Outages

- Ambient Light

- Room Temp/Humidity

- Door Ajar

- Pressure Differentials

- CO2 Levels

- Cryogenics

Where Can I Buy SensoScientific Monitoring Equipment Online?

Shop online to view a wide selection of SensoScientific environmental monitoring and testing equipment.

Terra Universal offers end-to-end construction, outfitting, certification, and testing for a wide variety of controlled environments including cleanrooms, laminar flow hoods, glove box isolators, biosafety cabinets, and lab equipment.

Have a technical question that requires a prompt and helpful response? Contact a Terra specialist via phone, live chat or email.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731