- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

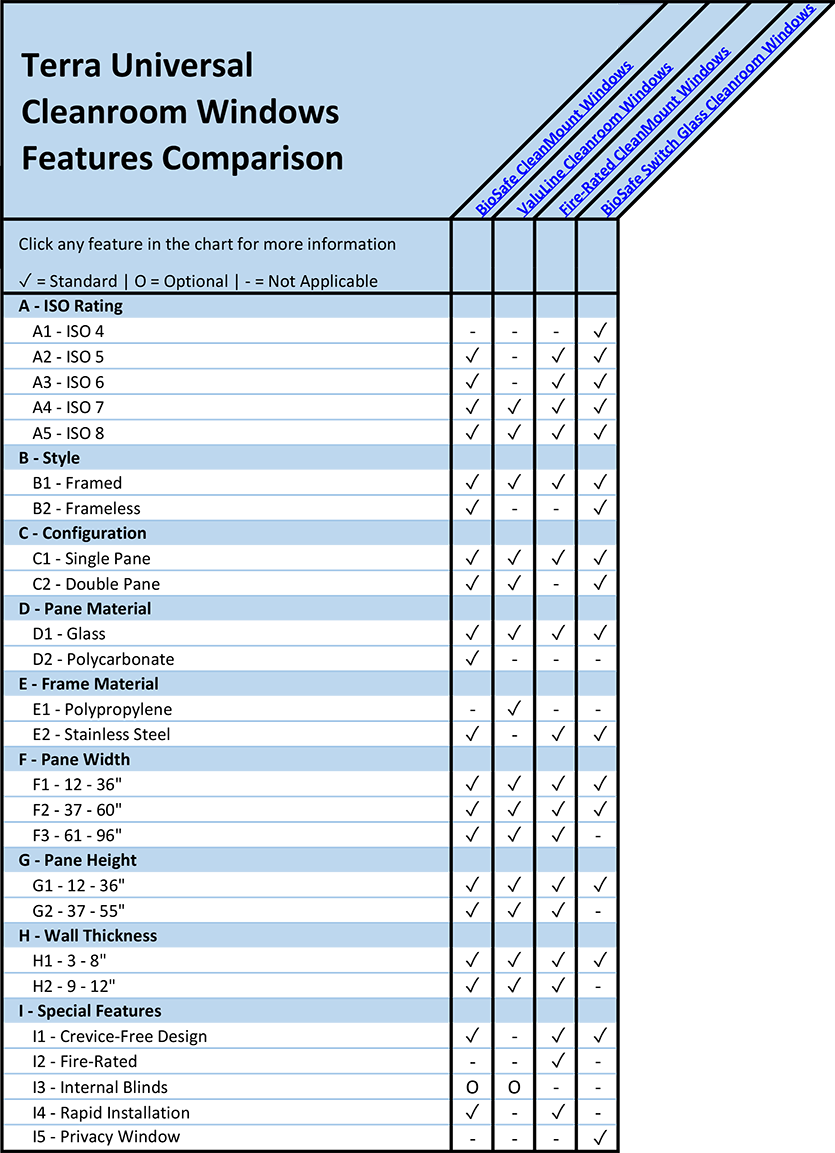

Cleanroom Window, Features, Styles, and Applications

Posted:

September 01, 2021

Cleanroom Window Features, Applications, and Styles

Terra Universal’s cleanroom windows are designed for quick and easy installation into stick-built or modular cleanrooms. Configured for health care, pharmaceutical, and CGMP facilities, Terra’s cleanroom windows are easy-to-clean, hygienic, support aseptic environments and enhance the visibility of operations and foot traffic. Terra’s broad portfolio of cleanroom window designs includes flush-mount, crevice-free, frameless BioSafe® windows, CleanMount™ fire-rated windows, economical ValuLine windows, and special-application designs including UL-listed and fire-rated windows. Switch Glass windows and internal blinds are optional for high-privacy areas.

A - ISO Rating

(back to chart)

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO 14644-1 provides guidance on monitoring and validating cleanroom conditions, establishing procedures for testing and evaluating air cleanliness, and ensuring ongoing compliance with the specified cleanliness levels.

Terra’s products are designed to comply with the below ISO 14644-1 classifications.

A1 - ISO 4

The maximum allowable concentration in an ISO class 4 environment is 10,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 4 cleanrooms, or enclosures, must maintain an average airflow velocity of 50 – 90 feet per minute and an average air change rate of 300 – 540 changes per hour.

A2 - ISO 5

The maximum allowable concentration in an ISO class 5 environment is 100,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 5 cleanrooms, or enclosures, must maintain an average airflow velocity of 40 – 80 feet per minute and an average air change rate of 240 – 480 changes per hour.

A3 - ISO 6

The maximum allowable concentration in an ISO class 6 environment is 1,000,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 6 cleanrooms, or enclosures, must maintain an average airflow velocity of 25 – 40 feet per minute and an average air change rate of 150 – 240 changes per hour.

A4 - ISO 7

The maximum allowable concentration in an ISO class 7 environment is 352,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 7 cleanrooms, or enclosures, must maintain an average airflow velocity of 10 – 15 feet per minute and an average air change rate of 60 – 90 changes per hour.

A5 - ISO 8

The maximum allowable concentration in an ISO class 8 environment is 3,520,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 8 cleanrooms, or enclosures, must maintain an average airflow velocity of 1 – 8 feet per minute and an average air change rate of 5 – 48 changes per hour.

B - Cleanroom Window Style

(back to chart)

B1 - Framed Cleanroom Windows

Terra’s framed cleanroom windows feature a 2.75”-wide, 304-grade stainless steel or polypropylene outer frame that mounts tightly against the cleanroom wall, allowing the glass pane to be recessed into the wall. The chemical-resistant frame provides a smooth, durable, and easy-to-clean surface.

B2 - Frameless Cleanroom Windows

Terra’s BioSafe flush-mount cleanroom windows feature an innovative CleanMount mounting system with no hardware or fasteners to support fast, easy installation.

Frameless windows include 0.25” thick tempered glass panels that overlay the wall surface on one or both sides. The glazing is attached to an internal stainless steel frame for a showcase appearance compatible with a variety of wall materials and thicknesses.

The windows are designed without any cracks or crevices where microbes can aggregate and colonize, supporting easy disinfection with biocides or alcohol-based cleaners. The black faux border rests behind the glass pane to prevent scratching or degradation over time.

B3 - Framed CleanMount™ Fire-Rated Cleanroom Windows

Framed fire-rated clean room windows offer frame materials and window glazing tested in accordance with UL 9 and NFPA 80 criteria.

Terra's CleanMount™ Fire-Rated Windows include a flush-mount fire-rated window with a 45-minute fire rating. UL-rated compliance includes UL 9 Fire Tests and UL File GVTV.R39784. UL 9 standards evaluate the ability of the window assembly to resist the spread of fire and heat for a specified period of time, while UL File GVTV.R39784 includes requirements for materials, design, construction, installation, and performance testing.

Read: What are the Advantages of Flush-mount Cleanroom Windows?

C - Cleanroom Window Configuration

(back to chart)

C1 - Single Pane Cleanroom Windows

Single-pane cleanroom windows, designed for installation between a cleanroom and a non-controlled space, feature a seamless stainless steel or polypropylene ledge on the opposite side of the glass pane for small part storage.

C2 - Double Pane Cleanroom Windows

Double-pane cleanroom windows, designed for installation between two critical spaces, feature flush-mounted, framed or frameless panes on both sides of the wall.

D - Cleanroom Window Pane Material

(back to chart)

D1 - Glass Cleanroom Windows

Frameless windows include a 0.25” thick, durable tempered glass pane while framed windows include a 0.5” thick tempered glass pane. Tempered glass is disinfectant-resistant, long-lasting, and provides high visual clarity.

D2 - Polycarbonate Cleanroom Windows

Impact-resistant and heat-resistant polycarbonate panes are optimal for equipment corridors, high-traffic areas, and spaces storing heat-generating equipment.

D3 - Fire-Rated Cleanroom Window Panes

Terra's single-pane fire rate window panes feature a Pilkington PyroStop technology, which is a type of single-glazed, multi-laminate that is approximately 7/8" thick.

E - Cleanroom Window Frame Material

(back to chart)

E1 - Polypropylene Cleanroom Window Frames

Terra’s ValuLine windows feature an economical polypropylene frame that resists chemicals and biocides.

E2 - Stainless Steel Cleanroom Window Frames

Terra’s BioSafe windows feature an aseptic, crevice-free, lipless frame composed of 304-grade, chemical-resistant stainless steel.

E3 - 316L Stainless Steel Cleanroom Window Frames

316L Stainless Steel Window Frames, standard on Terra's CleanMount™ Fire-Rated Windows, ensure a clean, durable, and robust material choice commonly prescribed for sterile bio-pharma applications.

All-316L stainless steel window surfaces offer enhanced corrosion resistance against harsher cleaning agents and better withstand degradation from bleach-based, disinfectants, as well as high-level sterilants including formaldehyde, vaporized hydrogen peroxide, and peracetic acid. 316L steel frame cleanroom windows exemplify components designed for medical-grade, USP-compliant applications, and are therefore compatible with many, if not all areas of a pharmacy, hospital, surgical theatre, or other types of aseptic environment.

F - Cleanroom Window Pane Width

(back to chart)

Terra manufactures all cleanroom window designs – framed, frameless, single-pane and double-pane – to exact project specifications between 12” and 96” in width.

G - Pane Height

(back to chart)

Terra manufactures all window styles to exact customer specifications, down 0.1” tolerances, between 12” and 55” in height.

H - Cleanroom Window Wall Thickness

(back to chart)

Terra’s windows are designed to accommodate modular cleanroom wall thicknesses down to 3” and stick-built, studded walls as thick as 12”.

i - Special Cleanroom Window Features

(back to chart)

I1 - Crevice-Free Flush Mount Cleanroom Window Design

Terra’s BioSafe windows feature a flush-mount system free of cracks or crevices that harbor microbes or contaminants. Terra’s BioSafe windows support easy wipe-downs, help maintain aseptic conditions, and install in fewer than 5 minutes.

I2 - Fire-Rated Cleanroom Windows

Terra’s CleanMount™ Fire-Rated Clean Room windows feature 3/16” thick tempered glass panels that are tested in accordance with UL 9 and NFPA 80 (National Fire Rating Association) criteria for a 20-minute rating.

I3 - Internal Cleanroom Window Blinds

Terra’s BioSafe and ValuLine cleanroom windows come with optional integral, cordless blinds for patient or research privacy.

I4 - Rapid Installation Cleanroom Windows

Terra’s BioSafe flush-mount cleanroom windows feature a CleanMount mounting system with no hardware or fasteners to support easy installation in fewer than 5 minutes. The CleanMount clamping design allows the window to be installed without drilling into the cleanroom wall. Internal brackets installed on each corner of the window frame may be adjusted to level the frame inside the wall cut-out.

I5 - Cleanroom Privacy Window

Terra’s BioSafe Switch Glass cleanroom windows are designed for patient and research privacy in medical facilities or research labs. The glass is operated via a wired switch or Wi-Fi remote control, toggling between clear viewing and opaque privacy.

I6 - CleanMount™ Fire-Rated Cleanroom Windows

Terra’s BioSafe Switch Glass cleanroom windows are designed for patient and research privacy in medical facilities or research labs. The glass is operated via a wired switch or Wi-Fi remote control, toggling between clear viewing and opaque privacy.

Terra's CleanMount™ Fire-Rated Windows are catered toward USP 795, USP 797, or hospital pharmacies that need fireproof ratings, as well as flush, crevice-free surfaces that support cleaning and sanitation in critical areas.

I7 - UL Listed CleanMount™ Fire-Rated Window Components

The specifications for UL File GVTV.R39784 cleanroom windows include requirements for materials, design, construction, installation, and performance testing. These specifications would ensure that the cleanroom windows meet the necessary safety and performance standards for use in cleanroom environments.

Where Can I Source Cleanroom Windows Online?

Shop Terra Universal online to view a wide selection of cleanroom window styles, materials, and specialty configurations. Terra Universal is a cleanroom specialized manufacturer that offers online and offline sales, end-to-end construction, outfitting, certification, and testing for a wide variety of controlled environments.

Try The Cleanroom Window Configurator

Terra's cleanroom window configurator is a fast and simple way to find the ideal cleanroom window size, material, and style. Enter your required window dimensions and immediately locate a wide selection of compatible cleanroom windows online.

Have a technical question that requires a prompt and helpful response? Contact a Terra specialist via phone, live chat, or email.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731