- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

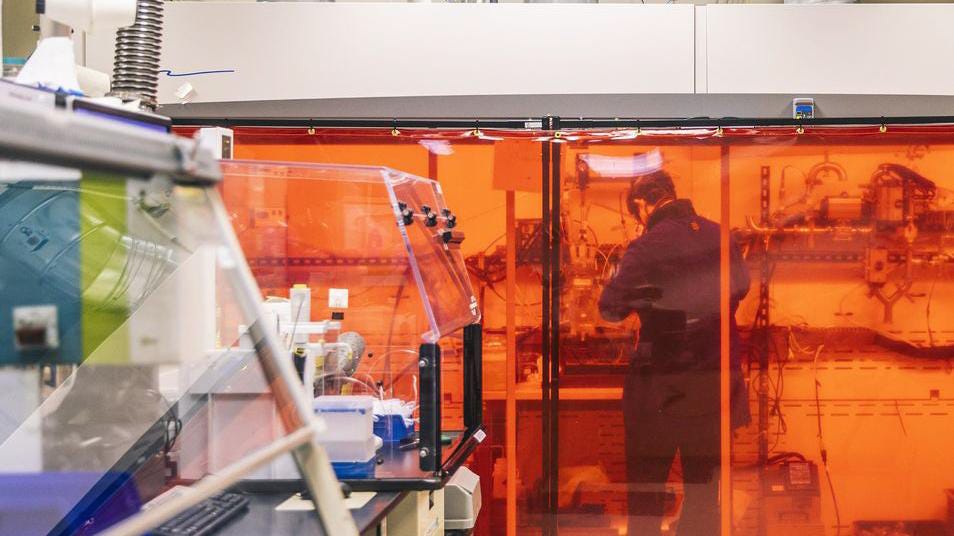

Specialized Glove Boxes and Environmental Enclosures for Battery Cell Manufacturing

Posted:

July 06, 2022

Challenges of Manufacturing Lithium-Ion Batteries

A Lithium-Ion battery consists of a cathode, anode, current collectors, and a porous separator that prevents shorting of the anode and cathode. As the Li-ion cell discharges energy, there is a significant increase in both temperature and the pressure exerted by the reaction. These two factors have the potential to result in a runaway chemical reaction, and ultimately an explosion. Thus, calorimeters must measure both temperature and pressure changes that occur to identify anomalies and prevent dangerous situations.

Lithium metal is an ideal anode material for rechargeable batteries but is also highly sensitive to humid atmospheres which encourage dendrite growth. Dendrites are often a root cause of short-circuiting within batteries, printed circuit boards, and other electrical circuits. Lithium-ion battery electrodes readily react with water and oxygen, thus increasing the risk of explosions, fire hazards, and chemical outgassing.

Overcoming Production Setbacks with Controlled Environment Gloveboxes for Lithium-Ion Batteries

One setback for high-performance rechargeable batteries is the production of CO2, CO, H2, and other gasses during lithium-ion battery cycling. Besides contributing to safety risks, gas evolution is also associated with declining cell performance factors such as electrode degradation, diminished shelf life, reduced cycle lifetime, electrolyte displacement, and increased cell impedance. Gas evolution arises from many sources in lithium-ion batteries including the decomposition of electrolyte solvents at both electrodes and the structural release from cathode materials. Byproducts such as hydrogen and organic ethylene can onset thermal runaway while also being inherently flammable. Thus, atmosphere-controlled glove boxes ensure that any gases generated in a testing or assembly environment are easily managed and removed from the test chamber via purging or filtration.

Anode Production Vacuum Requirements

Anode production requires a vacuum when removing moisture and solvents from the chamber, vacuum-degassing, enclosure sealing, and battery charging. Vacuum chambers allow the processing and assembly of battery components that rapidly oxidize or decompose when in contact with room air.

How Does a Vacuum Glovebox for Lithium-Ion Batteries Work?

Once a part or component is introduced to the internal chamber and the vacuum is applied to remove the room air, the chamber backfills with process gas (argon or nitrogen) until the chamber attains neutral pressure. When the chamber reaches the desired pressure, the vacuum controller maintains the pressure levels for a set duration and periodically reapplies the vacuum. At the end of the vacuum cycle, the chamber is backfilled with a clean, dry process gas (commonly nitrogen or argon) to restore neutral pressure. This cycle can be repeated as many times as necessary to attain the desired low humidity and low oxygen conditions.

Vacuum Glovebox Uses:

- Testing the electrochemical performances of electrodes

- Moisture free environment when constructing a coin cell

- Surface cleaning of lithium foil

- Li-metal extrusion and the assembly of cells with a Li-metal anode

- Determining the chemical composition of corrosion inhibitor/metal interfaces

- Cell assembly and leak-detection testing

Glove Boxes for Lithium-Ion Battery Assembly

Stainless Steel Gloveboxes for Battery Manufacturing

Stainless Steel Glove Boxes ensure ultra-low humidity and oxygen levels vital for processing battery cells. The environment is configurable to maintain <1 %RH with O2 and H2O levels maintained below 0.5 parts per million. For coin cells assembled in an argon-filled glove box, applications may require oxygen and moisture content below 0.1 ppm.

Stainless Steel Negative Pressure Gloveboxes offer a range of benefits for special applications that require only partial vacuum or slightly negative pressure. Stainless steel outgasses less than acrylic, is easier to clean, has higher chemical resistance, and is well suited for higher temperature applications.

Also referred to as negative pressure glove boxes, these systems offer a prototypical configuration for handling non-hazardous substances and support numerous add-ons and attachments for N2 or argon backfill. Terra gloveboxes are designed as positive-pressure isolation chambers that operate with a continuous inflow of process gas and include bleed valves to relieve overpressures. Unless specified, they are not designed as low-leak or air-tight containment chambers, nor should they be used with hazardous substances that require air-tight seals

Terra's 400 Series Stainless Steel Gloveboxes feature double gasket side flanges for easy insertion of large process equipment and easy mounting of an antechamber, vacuum systems, nitrogen purge, passthrough ovens, and standard airlocks.

Series 400 Glove Boxes are available with vacuum antichambers for intensive high vacuum testing. A 23-inch sliding tray extends 14 inches beyond the antechamber opening when fully extended to allow for easy loading of parts. With its high vacuum design and TIG welded structure, this antechamber has been tested and certified with no detectable leaks at a full vacuum with a helium mass spectrometer calibrated to 3 x 10-10 std. cc/sec (aluminum and stainless steel models only).

Series 500 Glove Boxes are stainless steel glove box chambers with glove ports and integrated HEPA or ULPA filtration systems. ULPA filtration maintains conditions equivalent to an ISO Class 5 cleanroom environment. Optional airlock systems provide a controlled environment for moving samples into and out of the glove box, and also reduce contaminant inflow during sample transfer.

Series 600 Glove Box Isolators provide a clean, controlled environment for a wide range of low-humidity, low-oxygen manufacturing processes for Battery cells, semiconductors, pharmaceuticals, and other industries. Applications include parts degassing, chemical mixing, and temperature/humidity testing.

Temperature Control Glove Boxes for Battery Cells

Insulated Temperature Control Glove Boxes provide thermal stability when testing the ionic conductivity of electrolytes, which is measured as a function of temperature. Other functions include:

- Control experiments using liquid electrolytes

- Battery assembly and battery disassembly

- Controlled temperature testing

- Storage and handling of hygroscopic chemicals

Double-wall, insulated glove box isolators boost thermal efficiency to create stable process temperatures and decrease the cost of heating and cooling cycles.

Terra's temperature control glove box systems include heated and refrigerated systems that range between -20°F to +140°F (-29°C to 68°C). Temperature control systems can be paired with optional gas purge systems for humidity control (5% to 95% RH) and/or HEPA/ULPA filters to provide a low particle atmosphere.

Terra Universal’s Process Gas Heater package provide a safe and accurate way to enhance a variety of sensitive operations requiring a heated process gas. Its programmable controller ensures safe, clean heating and provides over-temperature protection. Within a matter of seconds, it raises the temperature of the process gas (such as nitrogen, argon, or oxygen) up to 349°F.

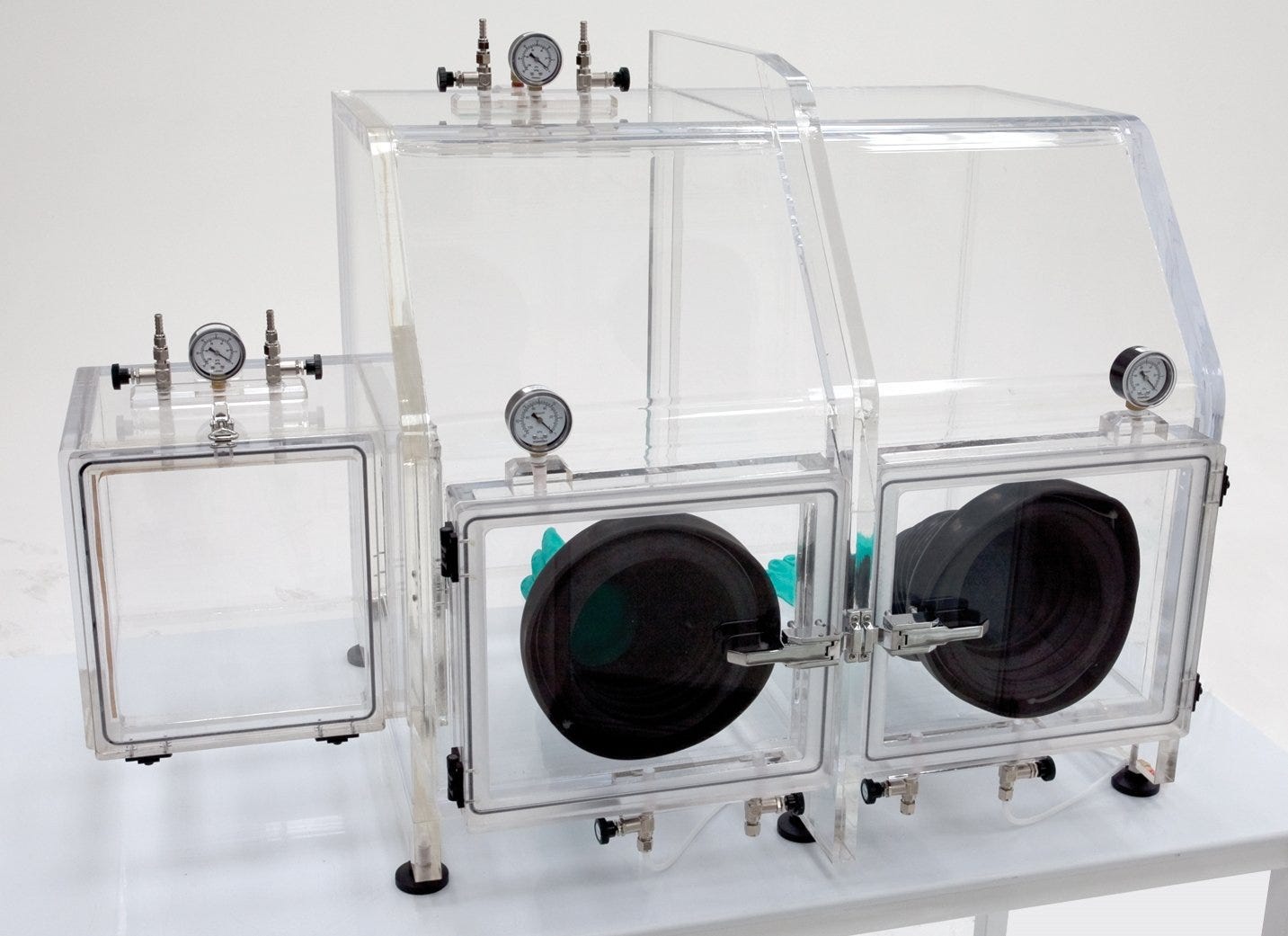

Acrylic Glove Boxes for Vacuum and Degassing

Vacuum glove boxes are ideal for vacuum cycling and process gas backfilling. This provides a fast, economical way to achieve extremely low moisture and oxygen levels inside the chamber. During each cycle, a vacuum pump connected to the glovebox removes ambient air from the chamber environment, and with it, removes the moisture and oxygen. Once the air is removed, the chamber can be backfilled with an inert process gas until the chamber attains neutral pressure. This process is repeated as needed until oxygen or moisture concentration reaches the desired level.

Acrylic Vacuum Glove Box designs are built with one-inch-thick walls to hold full vacuum down to 29.9" Hg (99.9% vacuum). These heavy-duty transparent vacuum gloveboxes include a built-in vacuum airlock to allow material transfer with minimal disruption to the internal atmosphere.

Terra's Series 210 Acrylic Vacuum Glove Box supports vacuum and degassing operations.

Depending on the configuration, advanced controllers are available to simulate program-specific atmospheric pressures, achieve target oxygen levels, or reproduce specific humidity set points when running multiple simulation series.

Optional Inert Gas Airlocks minimize nitrogen loss and contamination inflow when materials are passed through the glove box. The airlock is connected to an inert gas line to purge out ambient air before the inside door is opened to allow materials to transfer into or out of the main chamber.

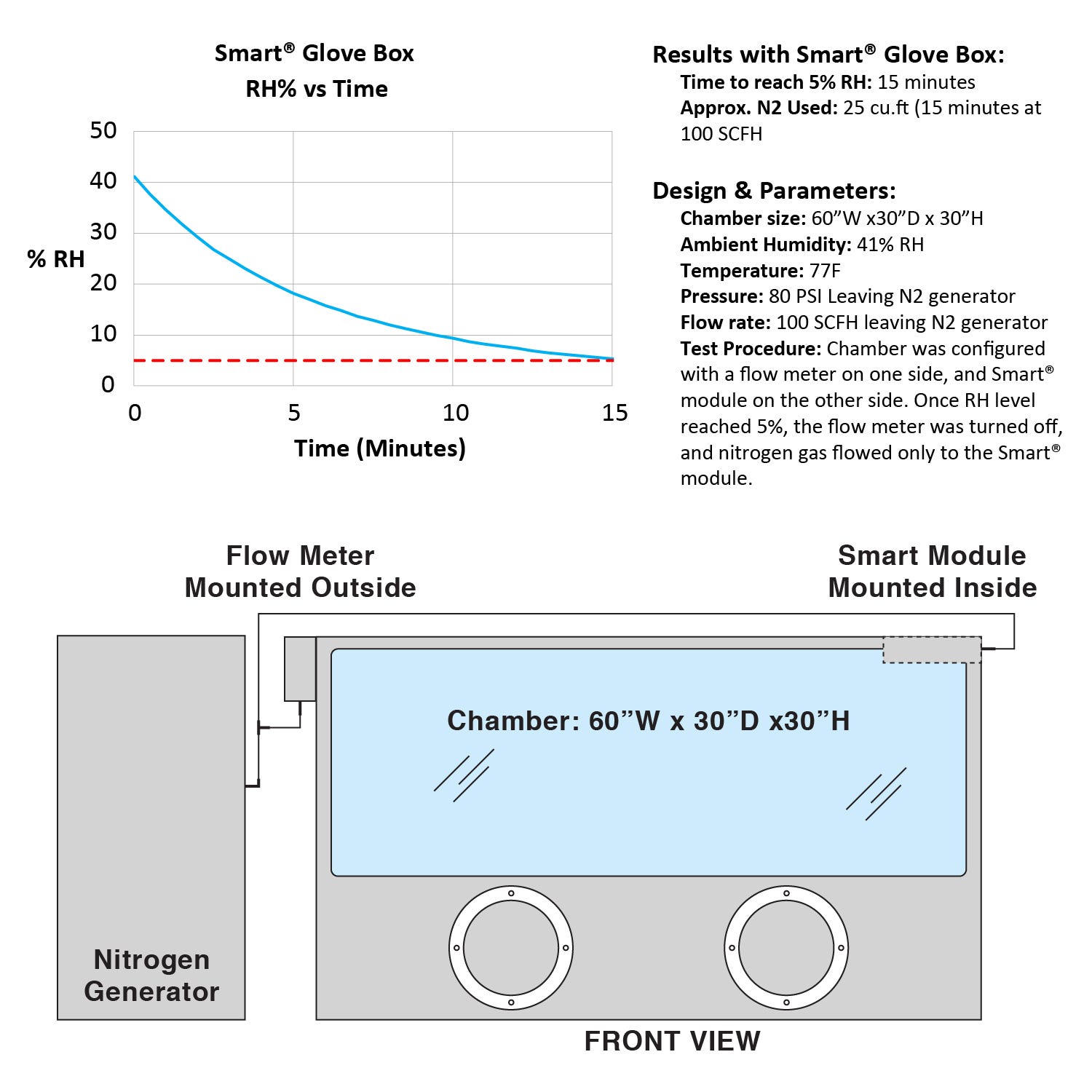

Smart Gloveboxes and Accessories for Lithium-Ion Batteries

Terra’s Smart® Glovebox Systems enable sample manipulation and throughput without removing materials from the test environment. These systems are configurable for automatically maintained humidity control, argon or nitrogen supplementation, and ESD safe materials for electrical components.

Terra's smart glovebox systems are available with numerous add-ons and accessories:

Automated Humidity Control

Automated humidity-control systems signal the system to purge when moisture levels rise above a designated set point.

Environmental Monitoring

Terra's DewWatch allows environmental monitoring between -80 and +20 degrees C at a threshold of 0.5 PPM to 23,000 PPM. The system integrates with Terra's Dual Purge™ System for completely automatic nitrogen purging.

Trace Oxygen Analysis

An integrated trace oxygen analyzer senses oxygen levels down to one part per million (ppm) which allows real-time monitoring, alarm triggering, and sending data to remote devices.

View All Glovebox Accessories and Add-Ons

[Header Image - Inset Smart Glovebox image below]

Battery Glove Box Material Construction Considerations

Static-dissipative PVC (SD-PVC) glovebox construction dissipates electro-static charges and eliminates static-cling of dust particles to help maintain clean surfaces.

Stainless Steel gloveboxes are suitable for heavy-duty, sterile, and ESD-safe applications. CleanSeam™ design features a fully-welded single-piece enclosure with smooth and seamless interiors to eliminate hard-to-clean cracks and crevices that can harbor contaminants.

Lexan Polycarbonate gloveboxes offer visual clarity plus several benefits over acrylic. Superior durability cracks less easily with 250x the impact resistance of glass, and 15x the impact resistance of acrylic. Chemical resistant formula withstands many cleaning agents such as isopropyl alcohol. Increased thermal resistance (115–130 °C / 239–266 °F) helps withstand repeated steam sterilization.

Plexiglass Acrylic gloveboxes offer durability (17x impact resistance of glass), superior clarity, and UV resistance (won't yellow from exposure to the sun).

Opaque white polypropylene glove boxes offer the best resistance to a wide range of corrosive acids, solvents, and disinfectants. The solid frame and walls feature continuous-seam welds for easy cleaning and maximum protection against chemical splashes and spills.

Read More: Gloveboxes - A Complete History

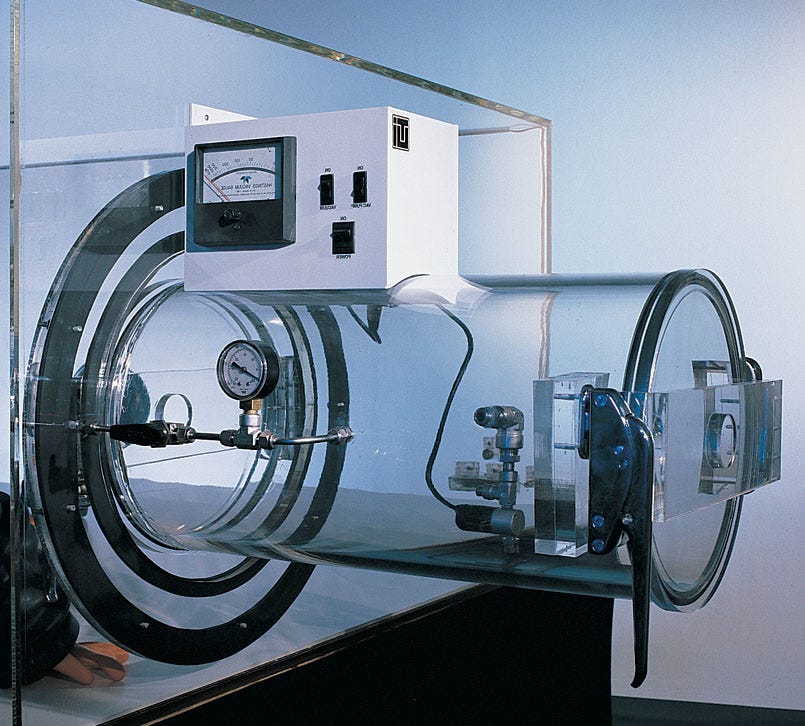

Battery Cell Manufacturing Vacuum Antechambers

Airlocks, and vacuum antechambers, allow chamber conditions to remain stable while adding or removing parts from the chamber.

Terra's Vacuum Antechamber assures a safe, contamination-free atmosphere for use with Terra’s Series 200 Polymer Glove Box or Series 400 Stainless Steel Glove Box. Together with a Terra Vacuum Control Model, the vacuum antechamber provides completely automated vacuum control at any point you require, down to 29.9" Hg.

What is a Vacuum Antechamber?

A vacuum antechamber, available in acrylic, aluminum, or stainless steel, allows you to perform moisture removal and other degassing operations on materials prior to transfer into the glove box without the risk of contaminating the chamber environment. It features a single center clamped, counterbalanced door for easy operation and sealing.

Vacuum Control Modules Advantages

The Vacuum Control Module automatically controls pump operation to maintain a preset vacuum level (to 800 Torr) inside the vacuum antechamber. This vacuum control is especially important in testing or processing applications that require sustained exposure to a precisely regulated vacuum level. A Vacuum Control Module also helps to extend the service life of your vacuum pump by allowing continuous pump operation. Repeated starts and stops, especially under existing vacuum pressure, can lead to the backstreaming of pump oil into the vacuum line, resulting in contamination and premature pump failure.

Li-Battery and Battery Component Storage Desiccators

Desiccators provide an inert gas environment for storing volatile chemicals and solvents associated with Li-battery manufacturing. They can also be used for slow, controlled drying, and are available with customized heating capabilities. The use of nitrogen or other inert process gas eliminates reactions caused by oxygen exposure.

Terra manufactures desiccators specially configured with ESD and static-safe materials when processing common microelectronics and electronics parts. These systems are readily adaptable for the storage of Lithium-Ion related battery components.

NitroPlex™ Adjust-A-Shelf Desiccator Cabinets offer a high-accuracy, miniaturized humidity module in each desiccator chamber that provides independent monitor/control capability. Using these modules, each chamber can be programmed to maintain a different humidity setpoint, from ambient down to 0%RH.

Desiccator storage cabinets maintain low humidity conditions and are configurable to relay real-time data on the internal storage conditions. Controlled storage reduces the likeliness of early-stage failures and also the “dwell effect” – the more costly damage that doesn’t emerge until battery components are installed in more complex assemblies, such as automobile battery cells, that are more difficult to repair or replace.

Continue Reading: Advantages of Terra Universal's Smart Nitro-Watch for Desiccator Cabinets and Glove Boxes

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731