- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

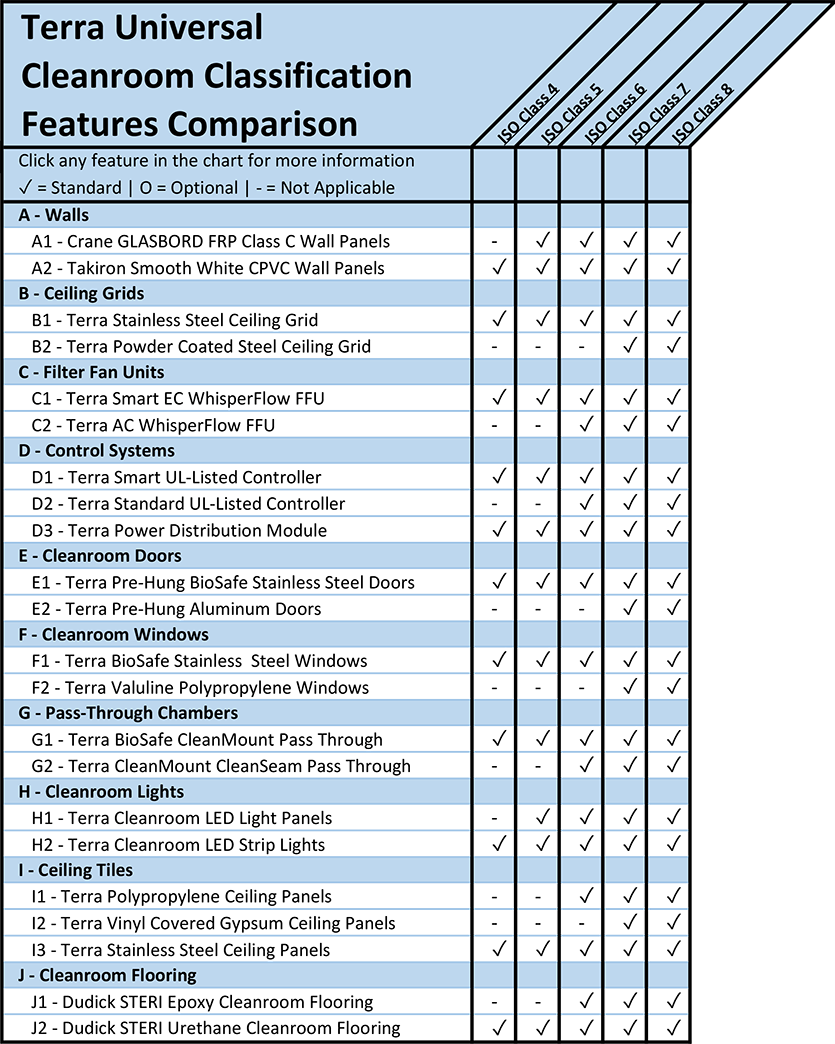

Cleanroom Conversion Packages Comparison: Doors, Windows, Lights, Panels, and Power Control

Posted:

September 15, 2022

Cleanroom Conversion System Comparison: Doors, Windows, Lights, and Panels

For retrofit projects converting an existing lab space into a cleanroom or cGMP area, the conventional solutions each come with unique challenges. New facility builds are cost-prohibitive, carry lengthy timelines, and hinge on the acquisition of a suitable facility. Depending on area requirements, installing a modular cleanroom inside an existing room is a fast, economical alternative, but often creates unusable or inaccessible space.

Mobile laboratories offer effective temporary solutions, but these portable facilities reside in far-flung areas of the property, causing staff to spend precious time transporting samples and reagents across campus. Terra offers a more economical and space-efficient approach: the Cleanroom Conversion Package.

Terra Cleanroom Conversion & Cleanroom Retrofitting Packages

Terra's cleanroom conversion system transforms any space - office, laboratory, warehouse, production area - into an ISO-rated cleanroom. The turnkey packages include all core components to renovate an unclassified space into a cleanroom, including ISO-compliant wall panels, modular ceiling grids, HEPA-filtered fan units, UL-listed control systems, BioSafe doors and windows, flooring and more.

Terra's broad portfolio of cleanroom systems include economical, ValuLine Softwall Modular Cleanrooms - Terra Universal for ISO-7 and higher spaces and BioSafe, aseptic, stainless steel models compatible with cleanrooms rated to ISO-4.

Our team of experts provides complete project supervision, including cleanroom design, technical drawings, seismic analysis, product manufacturing, delivery, installation, and project hand-off.

Get a Same Day Quote & Consultation

A - Cleanroom Wall Panels

(back to chart)

Crane’s GLASBORD fiberglass-reinforced plastic (FRP) wall panel system is certified for use in ISO-5 and higher cleanrooms. Applied with a non-outgassing polymer adhesive to most wall surfaces, including gypsum, the FRP panels are durable, non-contaminating and resist disinfectants and microbial growth. As compared to CPVC panels, FRP wall systems are more economical, but the panel’s uneven finish makes wipe-downs more laborious. Fire-rated panels are available upon request.

Takiron’s Class A CPVC (chlorinated polyvinyl chloride) panel system is certified for use down to ISO-4 environments. The solvent-free, non-outgassing adhesive ensures a gap-free seal bereft of cracks and crevices where microbes commonly collect. Takiron’s CPVC panels feature a smooth finish to promote easy wipe-downs and resist a broader range of chemicals than FRP panels, but carry higher up-front costs.

Read More: Saving Space with High-Speed Roll Up Cleanroom Doors

B - Cleanroom Ceiling Grids

(back to chart)

Terra’s modular grid structure mounts directly to existing walls to form a cleanroom-compliant drop ceiling. The powder-coated or stainless steel interlocking design requires no external bracing, including column supports or suspension cables, and spans up to 20’ in length. The grid’s standard 2’ x 4’ ceiling bays support cleanroom ceiling components, including HEPA-filtered or ULPA-filtered fan units, LED or germicidal UV lights, emergency lights, fire suppression sprinkler systems, feed-throughs and ISO-rated ceiling panels.

C - Cleanroom Filter Fan Units

(back to chart)

Terra manufactures and stocks a wide-range of ULPA- and HEPA-filtered fan units in all industry standard sizes, including room-side and top-side replaceable units, stainless steel and powder-coated steel models, energy-saving EC or industry-standard AC fans, reverse-flow (negative pressure) or downward flow (positive pressure) systems, explosion-proof models, units with integral ionizers, lights or heaters, low-profile models, and battery-powered systems.

In addition to particle filtration, HEPA and ULPA filters also capture a wide range of bacteria, viruses and mold spores that contribute to a host of infections and cross-contaminate lab samples.

D - Cleanroom UL-Listed Control Systems

(back to chart)

Terra’s scalable, plug-and-play, UL-listed control systems power a complete network of HEPA-filtered fan units, lights and electrical outlets. Significantly more cost effective than standard, hard-wired systems, Terra’s cleanroom control systems optimize room installation, relocation and maintenance and streamline room permitting, compliance and certification.

Terra’s UL-listed cleanroom control system is composed of several individual UL-marked products. Power distribution modules (PDMs) use quick-connect fittings to power all FFUs, lights and duplex outlets, irrespective of cleanroom size and scope. Smart cleanroom control panels include dynamic and programmable fan speed adjustment for energy savings and performance enhancement, empower remote shutdown procedures, and display real-time humidity, differential pressure and humidity conditions.

Fan filter replacement alarms provide a reliable and quantitative method for determining HEPA or ULPA filter replacement timelines, avoiding costly and unexpected operational interruptions. Ideal for nights and weekends, Terra’s Night Service switch drops all FFUs into low-energy operation mode, shaving energy usage by more than 25%.

E - Cleanroom Doors

(back to chart)

Terra Universal Cleanroom Doors

Terra manufactures and distributes a broad range of automatic / manual cleanroom doors and entry systems for cleanroom conversions and brick-and-mortar builds. Terra’s swing-out BioSafe doors, available in single- and double-door models, are pre-hung in a stainless steel frame for easy installation. This medical-grade, USP-compliant, leak-rated design includes continuous-seam welds to eliminate cracks and crevices for easy cleaning and sterilization.

View Terra Cleanroom Doors Dortek Ultra-Hygienic FRP Cleanroom DoorsDortek sliding and swing-out cleanroom doors feature ultra-hygienic FRP (fiberglass-reinforced plastic). The door is prehung in an FRP or aluminum wrap-around frame for easy site installation. Dortek’s systems are waterproof, chemical resistant, maintain correct room pressure and optimize air circulation. Other available door designs include fire-rated models, sliding and strip curtain doors, dual swing systems, automatic roll-up doors, and models composed of aluminum, tempered glass and ASTM-rated powder-coated steel.

F - Cleanroom Windows

(back to chart)

Terra Cleanroom Windows

Terra manufactures a wide variety of cleanroom windows, including framed and frameless windows, fire-rated models, single- and double-paned configurations, Switch glass windows, and systems with integral blinds.

Terra Biosafe Cleanroom WindowsTerra’s BioSafe windows mount flush to the cleanroom wall, eliminating cracks and crevices where microbes aggregate and colonize. BioSafe cleanroom window designs feature a smooth, 304-grade stainless steel or ASTM-rated powder-coated steel frame to support easy cleaning and sterilization.

Terra’s economical ValuLine windows include a chemical-resistant polypropylene frame compatible with all standard wall thicknesses. All cleanroom windows feature Terra’s CleanMount quick install system featuring a hardware-free clamping design enabling installation in under 5 minutes.

G - Pass-Through Chambers

(back to chart)

Terra manufacturers and stocks a broad portfolio of pass-through chambers, cart pass throughs, and transfer hatches for cleanroom conversions and stick-built projects.

CleanMount pass-through chambers support installation in under 5 minutes, mount flush to the cleanroom wall to support easy cleaning and disinfection. Terra’s BioSafe pass-throughs feature removable, autoclave-safe doors and coved, rounded corners for easy wipe-downs. Smart cleanroom pass-throughs feature a wide range of enhancements, including HEPA filtration systems, UV (ultraviolet) decontamination lamps, environmental monitoring systems, security access controls, BMS (building management system) integration and more.

H - Cleanroom Lights

(back to chart)

Terra’s ISO-rated cleanroom lights produce less heat (reducing cooling costs) and boast significantly longer lifespans than fluorescent bulbs. All stocked LED lights fit in industry standard 2’ x 2’ or 2’ x 4’ ceiling bays. Cleanroom LED panels with built-in emergency batteries illuminate the cleanroom during power outages. The systems include a test switch, battery-charge status indicator, and programmable time indicator light. LED strip lights mount to the ceiling grid to prevent obstruction of airflow laminarity. Optimal for ISO 3 – 5 spaces, the strips are installed in an aluminum housing covered by a clear, covered polycarbonate shield. Cleanroom-compliant germicidal UV lamps emit light at 254 nm to prevent microbial growth.

I - Cleanroom Ceiling Tiles

(back to chart)

Cleanroom-compliant ceiling panels cover 2’ x 4’ ceiling bays unoccupied by HEPA-filtered fan units or lights. 304-grade stainless steel panels comply with ISO-3 (and higher) environments, promote aseptic conditions, and resist corrosion.

Polypropylene ceilings tiles comply with ISO-5 (and higher) environments, resist chemicals and disinfectants, and promote easy wipe-downs. Vinyl-covered gypsum panels comply with ISO-7 (and higher spaces), resist alcohol-based cleaning agents, and reduce up-front costs.

J - Cleanroom Flooring

Dudick’s STERI urethane flooring complies with ISO-4 and higher environments, withstands corrosives and toxic spills, and inhibits growth of mold, mildew, fungus and bacteria. Dudick’s STERI epoxy flooring complies with ISO-6 and higher environments, resists mechanical abuse from heavy machinery, mitigates fire risk, and resists sanitation chemicals, organic solvents and disinfectants.

Compare a Wide Selection of Stocked and Ready-to-Ship Cleanroom Packages

Thousands of Terra cleanroom products are available with same week delivery including fan filter units, prefab cleanroom systems, and essential components.

- Orders ship from in-stock, on-hand, ready to ship selection

- Eliminate downtime and delays with same-day or same-week delivery

- Streamline compliance and installation with end-to-end UL rated components

- Factory leak tested filters and pre-packaged, ready to ship replacement filters

- Significant cost savings compared to standard, hard-wired systems

- UL-listed, scalable, plug-and-play cleanroom control system

Need Help with Product Configuration?

Shop Terra Universal Products Online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra Sales Specialist via phone, webchat, or email for help with configuration, large purchases, and application expertise.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731