ULPA Vacuums for Powders, Cyanides, Gloveboxes, and Cleanrooms

ULPA filtration vacuums are an indispensable tool when staring down challenging or potentially hazardous spills and messes in a laboratory or production environment. The most formidable of these messes typically include hazardous, poisonous, irritating, or nausea-inducing dust and powders that are fine enough to be aerosolized and distributed through the air as. To prevent aerosolized particle generation during cleanup and removal, specialized HEPA or ULPA vacuums are used to remove, capture, and contain these substances before safely disposing of them.

ULPA micro vacuums, such as Terra's MicroVac provide an all-in-one capture, containment, and recapture system that can prevent various exposures to chemicals and toxins during cleaning, processing, and recycling procedures. For the cleanup of highly potent or toxic substances, it's essential that cleaning processes do not further agitate and accelerate particles back into the air where they can be easily inhaled.

Vacuum Cleaners & Indoor Pollutants

Occupational hazards, including exposure to contaminated air or toxic chemicals, are prominent in many industries including photography, chemical research, synthetic plastics, metal processing, electroplating, gold and silver industries, jewelry polishing etc. When vacuum cleaners are required to reclaim, recover, or remove substances from surfaces, equipment, or the product itself, it's important to use a vacuum that will not reintroduce contamination back into the air.

Standard Vacuum Cleaner Filters vs HEPA or ULPA Vacuums

The quality of a vacuum cleaner is largely contingent on the type of debris encountered, the type of surface, and the design and style of the vacuum. Many technical factors will influence the overall capture efficiency such as the flow rate, motor type, bag design, and most importantly, the type and quality of the filter.

Standard Vacuum Cleaner Filters

Research shows that many activities generate or distribute indoor pollution including smoking, cooking, or burning candles. Regarding non-burning pollution sources, some would be surprised to find that vacuum cleaning is perhaps one of the dirtiest cleaning tasks your home or office will ever encounter. When considering a vacuum for these processes, a vacuum's capture efficiency is one of the most important key performance indicators. In other studies, researchers found that 98% of total particles by number were found in the ultrafine particle size range (Dp <100 nm) during vacuum cleaning.

HEPA Vacuum Filters

HEPA-filtered vacuum cleaners are designed to reduce and prevent the number of contaminated particles within a room or space. With a particle entrapment efficiency of at least 99.97% of particles at a size of 0.3 microns or larger. HEPA vacuums provide a high degree of particulate entrapment for a range of fine particulates including spores, pollen, dust, and other allergens.

- High-efficiency particulate air (HEPA) filtered vacuum cleaners are recommended by the U.S. Department of Housing and Urban Development for cleaning lead-contaminated house dust.

- Unlike typical fiberglass-based HEPA bag filters found in consumer vacuums, Terra filters feature medical-grade HEPA technology that does not contain fiberglass. Thus, the exhaust air is safe to breathe and will not expel fiberglass particles into the nearby environment.

ULPA Vacuum Filters

For the most critical use cases, MicroVac is one ULPA vacuum option that is well suited to achieve 99.999% efficient particle removal. The ultra-clean, high-flow, positive pressure air can easily provide enough airflow to facilitate infill and exfil of large glove boxes or sterile enclosures.

- Hazardous dust containment for cyanide powder or APIs

- Gold, aluminum, and precious metal recovery

- 3-D printing support material clean-up

- Dry chemical spill containment & fume extraction

- Recover transdermal medications or irritative powders

Multi-Stage Vacuum Features

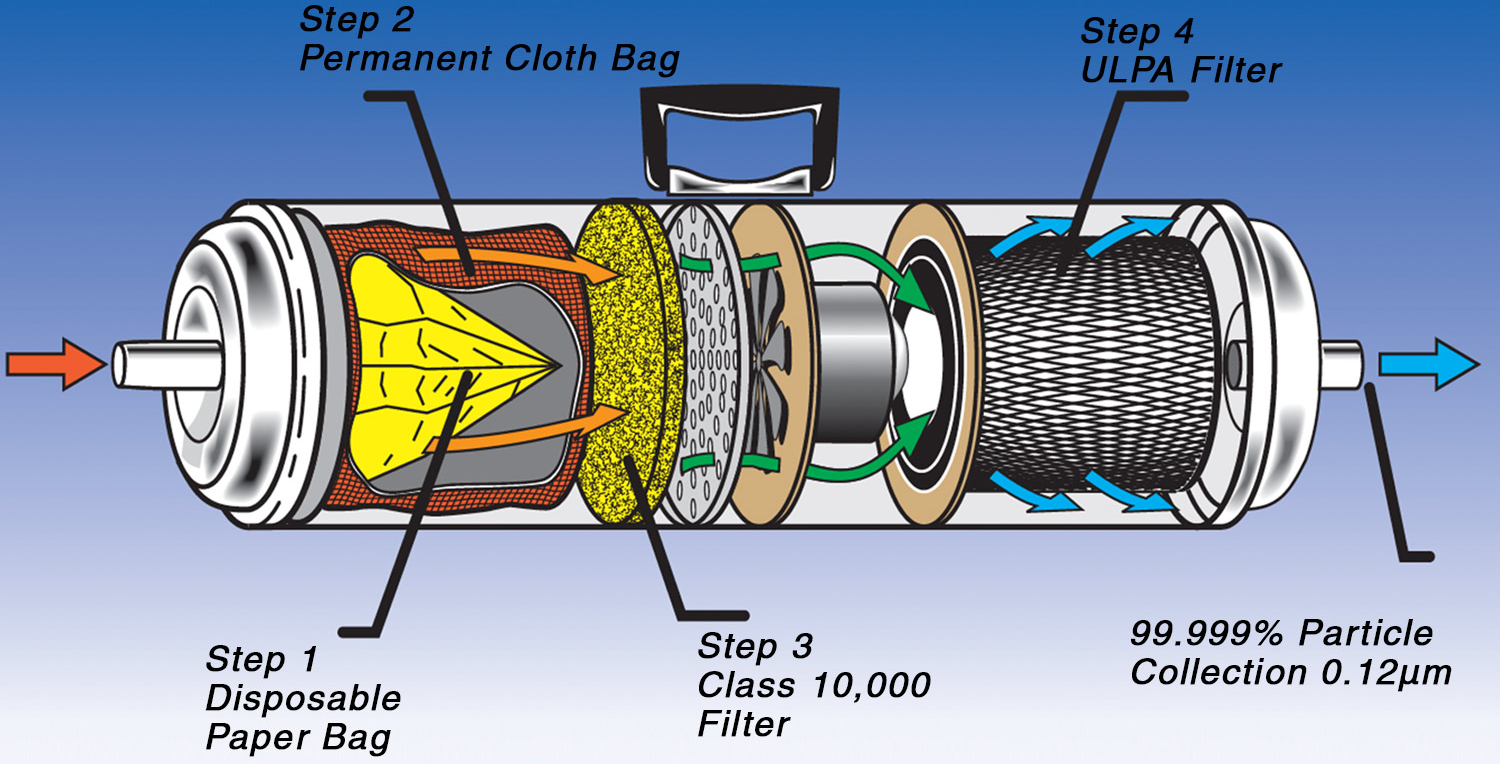

Four-Stage ULPA Filter Glovebox Vacuum with Multi-Purpose High Power Air Source

ULPA vacuum cleaners with multi-purpose, reversible outlet port can supply positive pressure ULPA air to a glovebox, or serve as a negative pressure air source during nitrogen backfilling. The powerful vacuum system is well suited to quickly ingress or egress large volumes of ultra-clean air.

Understanding MicroVac's Multistage Vacuum

- Stage 1: Disposable Paper Bag

- Stage 2: Permanent Cloth Bag

- Stage 3: Cleanroom-grade HEPA Filter (99.97% of particles 0.3µm)

- Stage 4: ULPA Filter (99.999% particle collection at 0.12µm)

Stage One / Two: The disposable paper bag for MicroVac portable cleanroom vacuum cleaner helps remove air’s largest particles, increasing the life and efficiency of the ULPA filter. During the first and second filtering stages, large particles are trapped in a disposable paper bag and inside a permanent cloth bag. The disposable bag filter fits inside the larger cloth bag filter directly inside the intake side of the MicroVac™, and the fine-mesh screen lies flush against the fixed stainless steel diffuser panel.

Stage Three: The integrated HEPA filter enhances total particle capture while also preventing oversize particles from impacting the downstream ULPA filter. An interim HEPA filter

Stage Four ULPA Filter: The glass-fiber ULPA filter removes particles 0.12 microns with 99.999% efficiency so that contaminated air can be safely extracted, filtered, and then immediately reintroduced back into the room.

Choose My Vacuum and Accessories

ULPA Vacuum Applications for Electronics

MicroVac Mini-Tool Kits are ideal for cleaning a wide variety of electronic devices including computer keyboards, input/output ports, PC boards, and other small parts or components. The vacuum attachments and mini-tools can also be connected to the outlet side of the MicroVac™ to direct and focus the stream of ULPA-filtered air.

For SMT circuit board manufacturers, the internal bag system allows the simpler recovery of precious metals such as silver and gold. The air hose can be attached to either side of the MicroVac, allowing use as a vacuum or a clean-air blower.

ULPA Vacuums for Recovery of Sodium Cyanide or Potassium Cyanide

MicroVacs are well-suited ULPA vacuums for capturing toxic, transdermal, or carcinogenic substances from an enclosure, surface, or glove box to allow safe indoor air release. This includes sodium cyanide and potassium cyanide which are used in chemical manufacturing, printing, fumigation, electroplating, and extracting gold and silver from ores.

The system is well suited for the recovery and vacuum conveying of pharmaceutical powders within an enclosed stream of air or nitrogen, including highly-potent medications such as fentanyl.

ULPA Vacuum Applications:

- Hazardous dust containment for cyanide powder or APIs

- Gold, aluminum, and precious metal recovery

- 3-D printing support material clean-up

- Fume extraction

- Dry chemical spill containment

- Recovery of transdermal medications or irritative powder

ULPA Vacuums for Cleaning 3D Prints and Collecting Support Materials

MicroVac is an excellent option for various 3D printing support processes, including the cleanup, reclaim, and recycling of support materials. Currently, Terra's MicroVac customers include some of the world's foremost 3D printing companies. Briefly, let's discuss what makes ULPA-filtered vacuums invaluable for 3D printing support materials processing.

Studies show that 3D printers produce a broad spectrum of particles. In focus, the smallest of these particles present the most potential for adverse health effects when respiration. Problematically, most standard vacuums or shop vac systems are not equipped to remove, filter, and scrub extremely small particles in great quantities.

Most people associate 3D printing with a nozzle-jet, high-temperature thermoplastic extrusion that slowly builds a 3D print by depositing a few micron layers at a time. Other 3D printing technologies, such as powder bed fusion and binder jetting, do not use heated, extruded nozzles to facilitate part building.

One advantage of powder-based 3D printing is that the method is compatible with novel materials such as foundry sand, ceramics, metal composites, and silica. Further, a significant degree of residual powder is left over after the printing process. To prevent material waste, reclaimed filament powder can be collected and recycled for additional prints. Naturally, these materials tend to be challenging to clean up because most vacuum system filters become clogged, generate backpressure, and expel particles back into the nearby air.

ULPA Vacuums for SLS and Binder Jet 3D Printing

ULPA Vacuums provide a range of nozzles and attachments to remove excess support materials from various parts and 3D printing exclosures. MicroVac offers a range of tip attachments that can access and extract excess materials from cavities or crevices within the parts.

In cases where the 3D printing materials are reclaimed and recycled, ULPA MicroVacs include a collection chamber for harvesting recyclable support material from the 3D printing enclosure. For closed chambers, MicroVacs can also provide benefits in the pre and post-stages of printing by removing any suspended particles from the chamber before, during, or after the print.

ULPA Vacuums for Cleanrooms

Cleanroom-rated ULPA vacuums are typically specified for cleanliness levels between ISO Class 4 - ISO Class 8 cleanrooms. Weighing only 10 lbs, Terra's MicroVac vacuum comes complete with an ULPA exhaust filter, 3' flexible hoses, two 20" extension wands, a crevice tool, five extra disposable bags, and a carry case with a mini tool kit. Improvise as needed, wherever it is needed, with various accessories and attachments to enhance the control of blown or vacuumed air.

Glovebox ULPA Vacuums

Microvac vacuums feature a 4-stage ULPA vacuum conveyor system that can supply, backfill, or exhaust ULPA filtered air to and from both negative and positive pressure glove box systems. This system is well suited for removing fumes, moisture, dust, contaminants, and residual materials from glove boxes or equipment enclosures.

The reversible outlet port can introduce ULPA filtered supply air from the immediate environment or connect to an air supply system such as nitrogen or argon gas tanks.

When configured to reverse flow, the system facilitates exfiltration of air to create negative pressure for nitrogen backfilling operations. The powerful vacuum system is well suited to quickly ingress or egress large volumes of ultra-clean air to support virtually any size glovebox.

- Conduct cleanup of particulates that gather in cracks, corners, and crevices

- Evacuate and filter chamber air before recirculating to an inside environment

- In-fill the chamber with ultra-clean, ULPA purified air

Vacuums for Pharmaceutical Powders and Particulate Collection

MicroVac ULPA vacuums are well suited for the recovery and vacuum conveying of pharmaceutical powders, including highly potent or potentially intoxicating medications such as fentanyl. Extremely fine powders present a difficult cleaning challenge. Powdery substances are easy to spill, easily become airborne when distributed, and can travel long distances and suspend in the air for long periods of time. Meanwhile, efforts to remove powders with typical vacuum systems would capture some degree of the material, but would also recirculate some degree of particles into the air.

Need Help with Product Selection or Purchasing?

Terra Universal Online offers a wide selection of HEPA and ULPA vacuum cleaners for unique facility needs including hospitals, pharmaceutical production, sterile processing, electronics fabrication, and cleanrooms.

Contact a Terra cleanroom specialist for assistance with product configuration or application compliance via web chat, email, or phone.