- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Charcoal Filters 101 for Critical Environments

Posted:

October 19, 2015

What is Activated Charcoal Filtering?

Activated charcoal is highly porous carbon used in air filters to capture solvent fumes and organic compounds by adsorption of molecules (van der Waals forces).

Unlike particle filters, which rely on micro-pores to capture solid contaminants suspended in air, activated charcoal filters are designed to entrap molecular contamination.

Terra’s coconut-shell-based charcoal filters remove a wide range of chemical fumes and odors common to laboratories and manufacturing environments. To understand chemical vapor filtration, let’s first focus on what having a carbon-based filter means.

How Are Activated Charcoal Filters Made?

There are a couple of methods to making charcoal active.

Terra’s charcoal filters undergo a chemical heating process. This results in millions of diminutive pores that increase surface area bonding sites to adsorb molecules— far more efficient than a non-activated charcoal filter. Forming accordion folds with the material further increases the ability of Terra’s charcoal filters to effectively remove fumes and odors. A larger surface with more adsorption sites leads to a longer-lasting filter.

HEPA / ULPA vs Activated Charcoal Filter Differences

Activated charcoal filters are extremely effective at adsorbing fumes in a negative pressure controlled workspace where contaminant containment is vital. While HEPA and ULPA filters capture most airborne particulates, they are incapable of removing the odors that may be released into your controlled space from either chemicals or by-products of your application tasks. Certain non-hazardous chemicals can act as irritants to personnel who work in close proximity to them for long periods of time. If these odors are not removed, personnel productivity levels go down and safety concerns go up.

Activated Bonded Charcoal Filter for Fume ScrubbingBonded-charcoal design minimizes voids, improves efficiency, reduces particle sloughing

Uses: Multiple volatile organic gases/solvent vapors and inorganic gases; fumes, food odors, body odors, perfumes, ozone.

Activated Bonded Charcoal/ Permanganate Oxidant Blend FilterUses: Cigarette smoke, fumes, ethylene, aldehydes, food odors, paint, multiple organics, hydrogen cyanide, NOx, SOx,

Caustic Impregnated Activated Bonded Charcoal FilterUses: Inorganic acids, chlorine, NOx, SOx, hydrogen sulfide

Multigas Impregnated Activated Bonded Charcoal FilterUses: Mixtures of acidic and basic vapors, mixtures of volatile organics and inorganics with ammonia, amines.

Permanganate Oxidant Blend Activated Bonded Charcoal FilterPermanganate oxidant protects against chlorinated aromatics corrosives, hydrides, alcohol, VOCs

Fume Hoods Activated Charcoal Filters

Terra’s activated charcoal filters for fume hoods and overhead canapy hoods approach 100% in their capture efficiency with common organic fumes like hydrocarbons, creating a safer, more comfortable environment. They can be used in chemical or ductless exhaust fume hoods and when used in a fan/filter unit (FFU), the carbon filter can be paired with a pre-filter, or HEPA or ULPA particle filter. Additionally, impregnated charcoal filters can optimize performance with specific chemicals. Caustic-impregnated carbon protects against organic and mineral acids, halides, VOCs, and sulfur compounds, while acid-impregnated filters safeguard against amines and acetate.

Cleanroom Charcoal Filter Replacement Intervals

Just like your at-home water filter, cleanroom-activated carbon filters have a service life. Over time, molecules accumulate in the filter, depleting the available chemical bonding sites on the filter. When this occurs, the filter has reached its Threshold Limit Value (TLV) and needs to be changed. The TLV frequency varies depending on the operating conditions and the type of chemical compounds being filtered.

When Should I Replace an Activated Charcoal Filter in Cleanrooms or Controlled Environments?

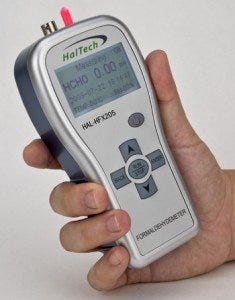

When particle filters need to be changed, you will notice changes in pressure differential and velocity. For charcoal, there are two effective ways to know when a replacement is needed:

- The filter is heavier than when it was first installed (so take a baseline weight before you start using it).

- You will start to detect odors that have slipped through the filter, telling you that it’s saturated.

You can also use chemical detector equipment to test for the presence of specific vapors in the filtered air. By monitoring filter performance closely when the system is placed in operation, you can set a replacement schedule. As long as working conditions are relatively consistent, filter replacement should take place within the same approximate period of time.

When it comes to the safety and comfort of your cleanroom operations, activated charcoal filters provide coverage that HEPA and ULPA filters can’t. Their efficient and effective porous surface adsorbs most airborne chemical fumes and odors—an irritant that, with prolonged exposure, may disturb or even harm personnel. A comfortable and safe working environment will increase efficiency and productivity.

Read More: Ultimate HEPA / ULPA Filter Particulate and Capture Efficiency Guide

Shop Cleanroom Charcoal Air Filters Online: Activated Charcoal FiltersTerra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731