- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Where do most cleanroom contaminants come from? Simple: the cleanroom staff brings them in. With enough foot traffic, outside contaminants can easily migrate into your cleanroom — but the right safeguards will help your facility stay clean and compliant.

Welcome to Terra’s multi-part educational series on critical environments. Let's discuss selecting the right cleanroom protocols and procedures for your application.

Additionally, we’ll outline proper gowning procedures, as well as the Terra Universal equipment you’ll need to protect your room from cross-contamination.

As humans are the primary source of contamination in cleanroom and lab environments, cleanroom-compliant hand washers, sinks and hand dryers play a critical role in reducing bioburden and viable particle counts within sterile spaces.

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO

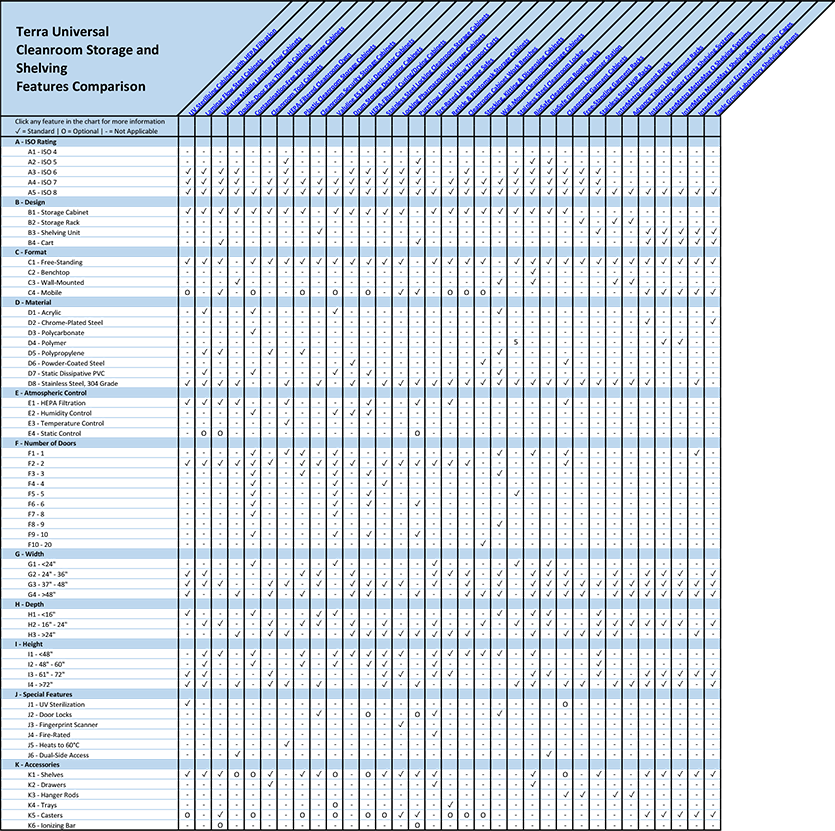

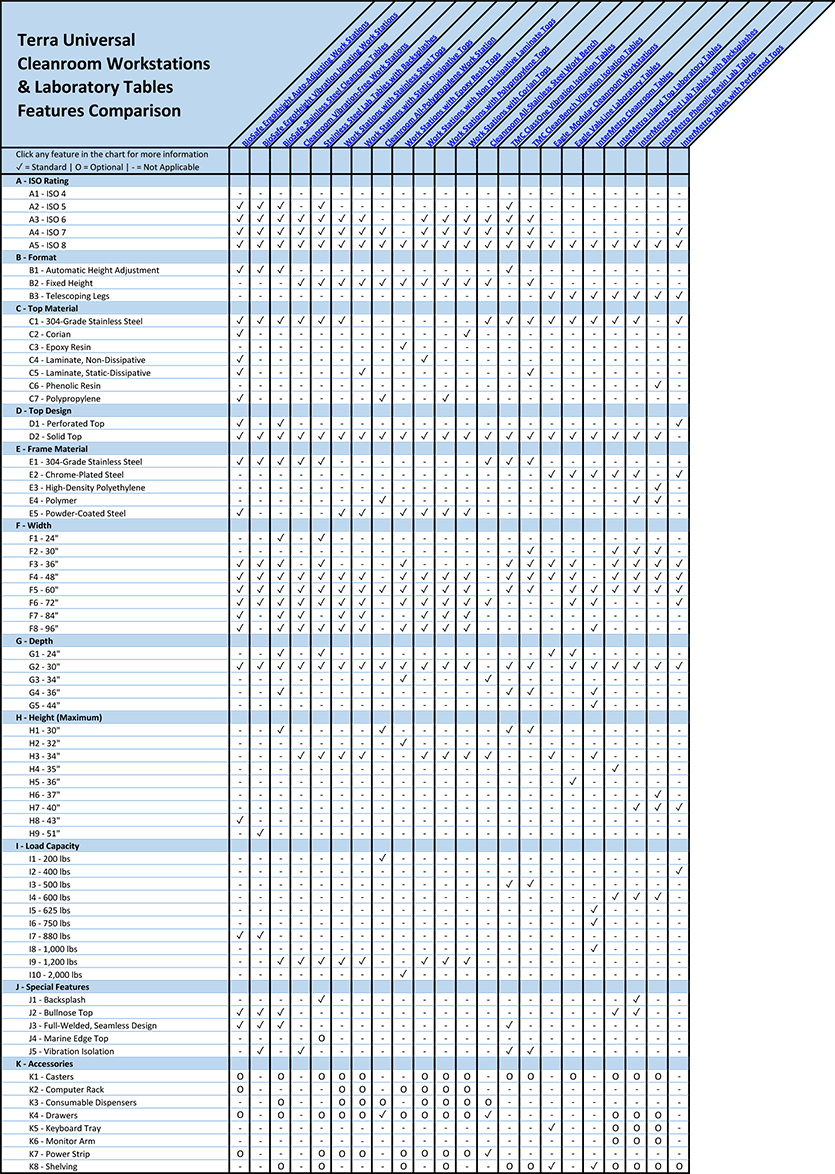

Terra Universal manufactures application-specific cleanroom workbench packages for a variety of uses, many available for immediate shipment and delivery from its Fullerton, California facility.

Terra also offers a wide selection of cleanroom specialized equipment from the following manufacturers:

Eagle (on-budget cleanroom tables and storage)

Metro (gowning furniture, modular tables, keyboard trays, monitor arms & drawers)

TMC (pneumatic vibration-isolated tables)

View All Cleanroom Workstations and Tables

ISO 14644-1 is a widely recognized

If you've ever inspected the feet and casters of typical office equipment, most are inhabited by a fine layer of dust, organic matter, and detritus. In most environments, objects that come in contact with the floor are expected to be dirty. In cleanrooms, maintaining ultra clean flooring is a key battleground in preventing the continual spread of contamination from one workstation or work area to another.

The appropriate choice of cleanroom chairs, carts, ladders and other free-standing equipment will ultimately affect the lifespan, ease of cleaning, and overall aesthetic of a cleanroom floor. Casters and leveling feet are particularly important for cleanroom floors with sensitive antibacterial or ESD surface coatings.

Whether outfitting a chair for a specific task or facility-wide outfitting, Terra Universal carries a wide selection of seating options catered for static-sensitive and cleanroom environments.

Sitting still can feel like a rocking ocean when staring through an unstable microscope — persistent viewing of blurry, shaky objects at high magnification causes nausea, headaches and fatigue. But the symptoms of motion sickness go beyond an upset stomach.

Sitting still can feel like a rocking ocean when staring through an unstable microscope — persistent viewing of blurry, shaky objects at high magnification causes nausea, headaches and fatigue. But the symptoms of motion sickness go beyond an upset stomach.

Headaches can cause visual disturbance. If it isn’t hard enough trying to view an unsteady slide, add minor loss of vision, ocular pain and photosensitivity to the equation and find out just how efficiently the observation goes—studying contents under a microscope requires the ability to see, after all.

Nausea from motion sickness can cause sweating and vomiting, which halts production. Facing such

Cleanrooms are used to perform clean processes, so it’s counterintuitive to think of maintenance and repair activities inside a controlled environment. Yet, they are very necessary and performed quite often. Protocol for crews working inside a cleanroom is different than the typical office space: personnel must gown and adhere to strict clean processes, just like lab technicians. The equipment crews bring into the cleanroom must also be compatible with the required ISO rating. Slow, careful movements and meticulous control over dust and other contaminants are critical to prevent complete shut-down and time-consuming recertification of the room.

Seems like a cleanroom is no place for a ladder: a dirty, dusty, paint-smeared structure used by the contractor who does the termite repair on your house. But in fact, cleanrooms are perfectly-suited to ladders, if they are Terra’s BioSafe brand. Cleanroom and lab ladders are used to access out-of-reach filters, lighting, or equipment. For example, taking particle measurements and airflow readings below the filter face in preparation for an ISO inspection may require a ladder. And what about changing light bulbs and making small repairs? Terra’s shelf platform can be attached to ladders, providing a convenient surface for tools and small instruments.

BioSafe folding cleanroom ladders have a number of unique features that make them ideal for aseptic

BioSafe folding cleanroom ladders have a number of unique features that make them ideal for aseptic

Cleanroom entrances present a significant potential for contaminant infiltration, so they must be managed with this in mind. Air showers are one way to minimize piggy-backing contaminants. They are enclosed chambers that use strong bursts of air to dislodge particulates from people or transport carts entering or exiting the room. Room entrances, and pass-throughs that incorporate an air shower, serve as a safeguard between critical and non-critical areas. Personnel are the greatest source of contamination in a cleanroom, so most of the methods of contamination reduction, including air showers, were developed to accommodate humans. Air showers range in size and construction, depending on the application, and are utilized by a diverse range of industries. So, how do air showers work? Find out below!

Air shower design and operation

Modular air shower chambers and tunnels use high-velocity streams of