- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Where do most cleanroom contaminants come from? Simple: the cleanroom staff brings them in. With enough foot traffic, outside contaminants can easily migrate into your cleanroom — but the right safeguards will help your facility stay clean and compliant.

Welcome to Terra’s multi-part educational series on critical environments. Let's discuss selecting the right cleanroom protocols and procedures for your application.

Additionally, we’ll outline proper gowning procedures, as well as the Terra Universal equipment you’ll need to protect your room from cross-contamination.

Manufacturers and research organizations spend considerable sums of money to ensure their cleanrooms adhere to critical cleanliness standards – disinfection procedures are optimized, quality controls are implemented and regular particle counts and microbial tests are performed to identify the smallest pockets of contamination. With many safeguards in place to limit contamination, including interlocking doors, pressure gradients, and air showers, the most common source of particles, whether viable or non-viable, stems from the cleanroom staff. The first line of defense in preventing human-borne particles from entering into a cleanroom is the gowning area.

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO

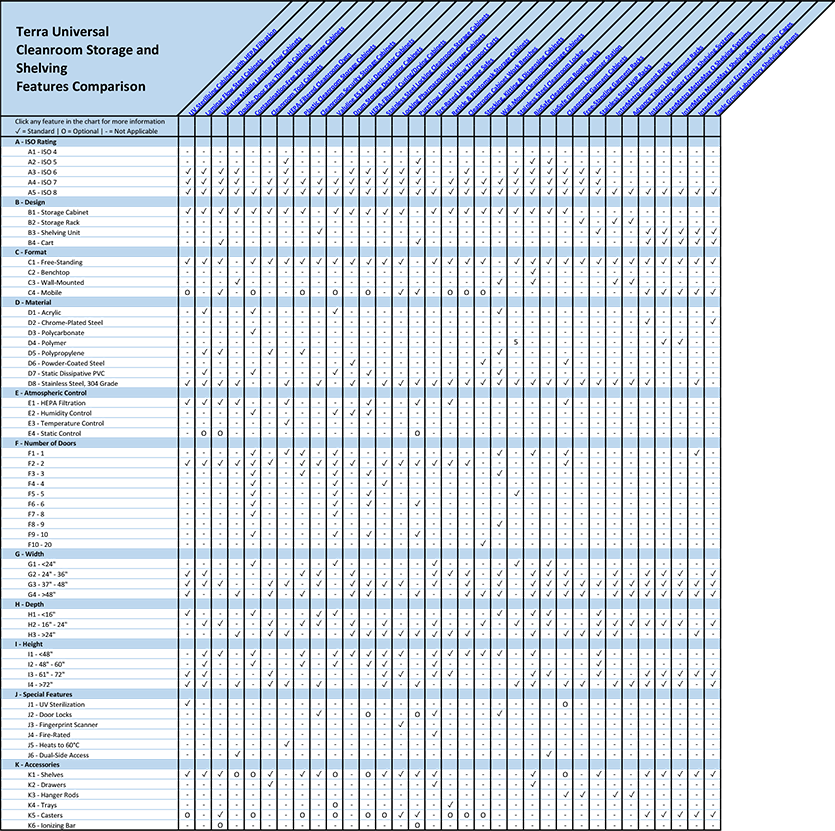

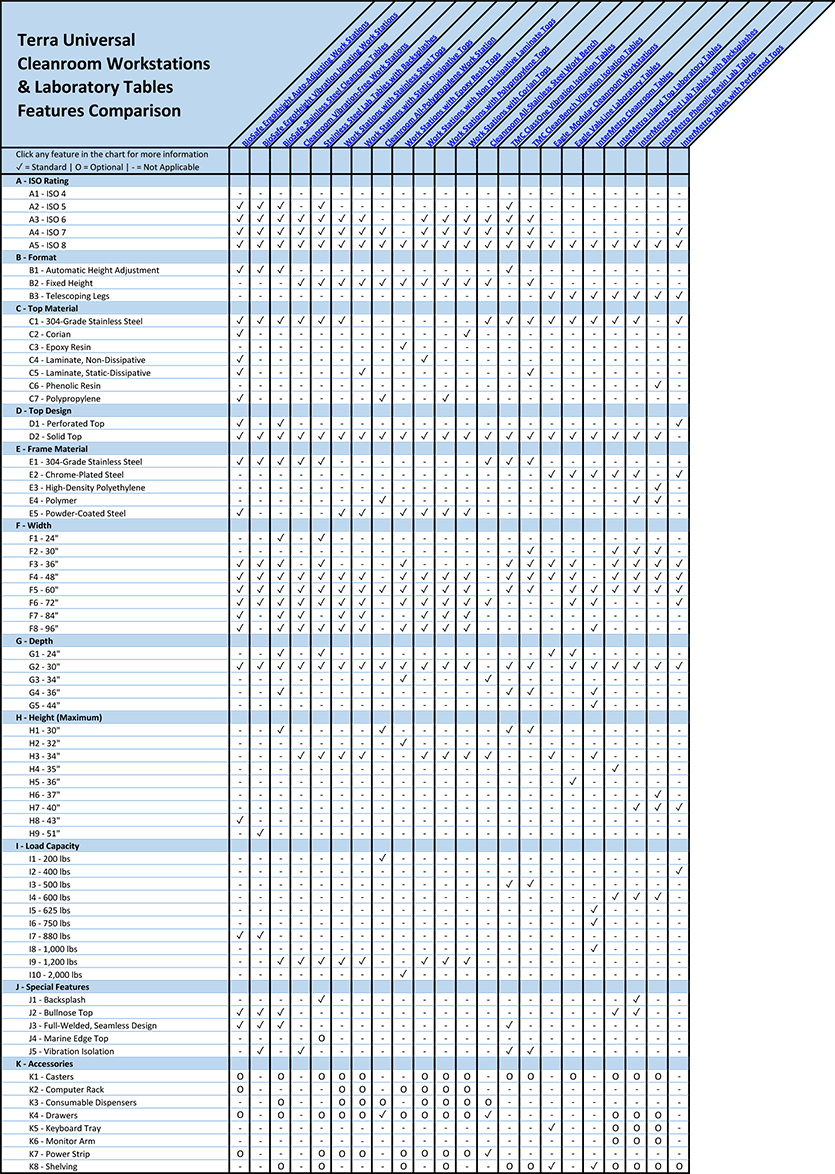

Terra Universal manufactures application-specific cleanroom workbench packages for a variety of uses, many available for immediate shipment and delivery from its Fullerton, California facility.

Terra also offers a wide selection of cleanroom specialized equipment from the following manufacturers:

Eagle (on-budget cleanroom tables and storage)

Metro (gowning furniture, modular tables, keyboard trays, monitor arms & drawers)

TMC (pneumatic vibration-isolated tables)

View All Cleanroom Workstations and Tables

ISO 14644-1 is a widely recognized

If you've ever inspected the feet and casters of typical office equipment, most are inhabited by a fine layer of dust, organic matter, and detritus. In most environments, objects that come in contact with the floor are expected to be dirty. In cleanrooms, maintaining ultra clean flooring is a key battleground in preventing the continual spread of contamination from one workstation or work area to another.

The appropriate choice of cleanroom chairs, carts, ladders and other free-standing equipment will ultimately affect the lifespan, ease of cleaning, and overall aesthetic of a cleanroom floor. Casters and leveling feet are particularly important for cleanroom floors with sensitive antibacterial or ESD surface coatings.

Whether outfitting a chair for a specific task or facility-wide outfitting, Terra Universal carries a wide selection of seating options catered for static-sensitive and cleanroom environments.

The last thing you need is your lab equipment rusting out on you. When considering your specific application needs for new stainless steel equipment, a recurring question in the market remains—what’s the difference between 304 and 316? When should you consider 316? In scenarios demanding the utmost vigilance, you may discover you require 316L stainless steel.

304 Stainless steel is composed of 18% chromium and 8% nickel. 316 Stainless steel is made up of chromium and nickel at 16% and 10% respectively, but also includes molybdenum—a silvery-white metal that’s highly resistant to corrosion.

316L Stainless steel contains the same corrosion-resistant materials as 316, but includes the added benefit of a lower carbon content—eliminating the opportunity for excessive metallic contamination and making cracking less likely. Both 316 and 316L are able to withstand chlorides and chlorinated solutions, such as Spor-Klenz® and Isopropyl Acetate.

Terra Universal specifically designs environments and furnishings to meet the needs of aseptic operations that must conform to strict FDA, cGMP and other standards involving potential microbial contamination. Bio-pharmaceutical applications require this level of sterile environment for successful disease research and drug development. We call this special line of products BioSafe®. What makes Terra’s BioSafe® solutions clean enough for sterile operations? The answer hinges on high-grade materials and easy-clean designs.

Smooth stainless steel (SS) construction (304 or 316 grade) is standard for many BioSafe® cleanrooms and other enclosures. These products also incorporate all-stainless steel hardware. Chrome-plated fixtures, unlike stainless steel, are subject to flaking and deterioration from metal-on-metal action, and can eventually rust if exposed areas