- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Did You Know? | Fan/Filter Units Do More Than Meet ISO Requirements—they also prevent infection

Posted:

June 05, 2019

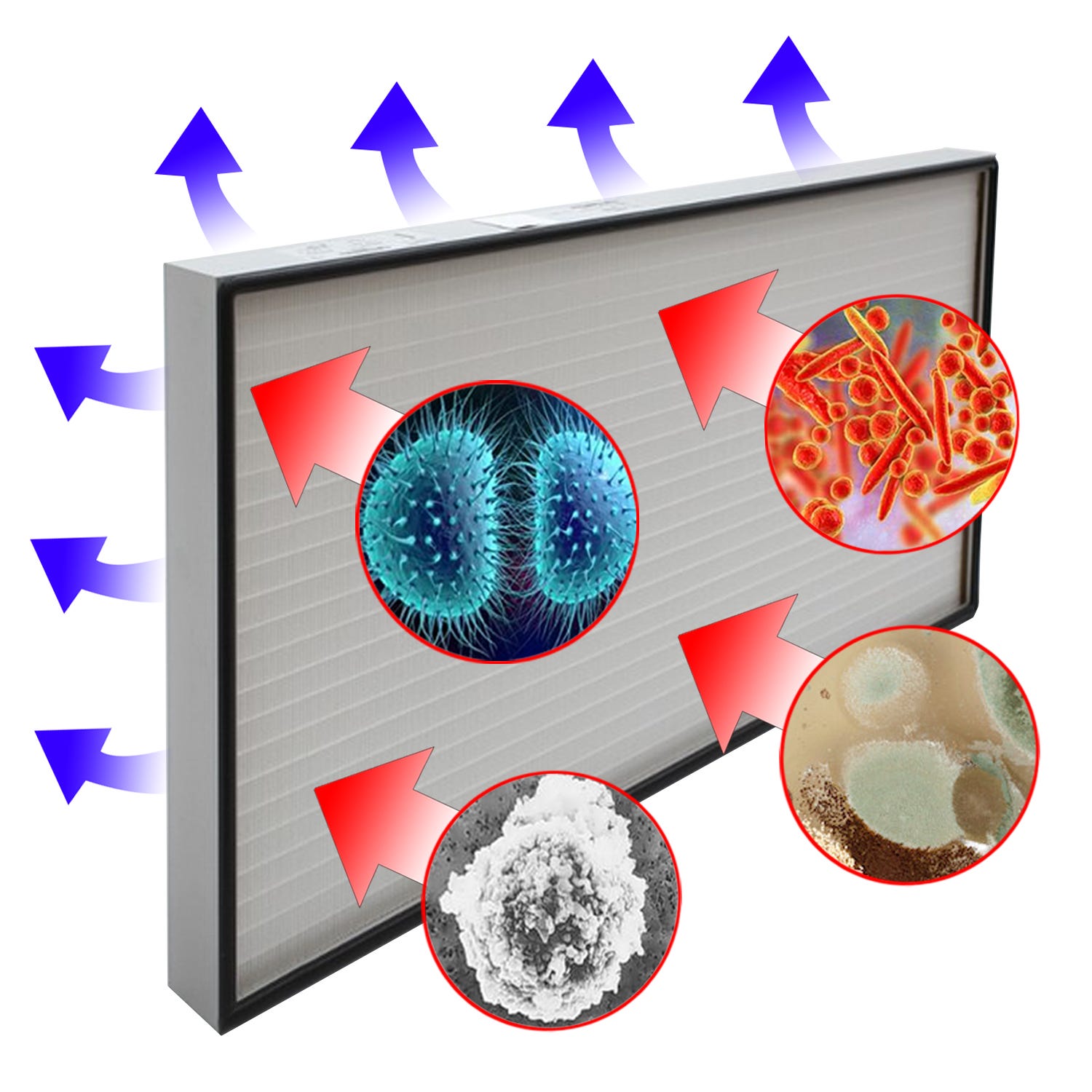

Most cleanroom professionals understand that Fan/Filter Units (FFUs) capture contaminants that degrade particle-sensitive samples. But they also remove bacteria, viruses and mold spores that contribute to a host of infections.

With the threat of superbugs on the rise in medical facilities, sterilization has never been more crucial. Superbugs, or drug-resistant bacteria that cannot be killed by standard antibiotics, have the potential to cause infections that are increasingly difficult to cure. The number of deaths related to these bacteria is decreasing. But the bugs, and the danger, remain present.

Until new cures are developed to battle bacteria, the solution to preventing the spread of germs is to update cleanliness procedures in hospitals, pharmaceutical manufacturing facilities and other places where drugs are regularly developed or used. Hand-washing can push back against the threat, but it’s important to implement protective measures against any potential breach, not just the hands of staff, equipment or patients. Airborne particulates present a hazard, too—and Fan Filter Units can help.

The filters inside the FFUs play the key role in the containment of pathogens. Most common bacteria are caught by the 0.3-micron pore size of High-Efficiency Particular Air (HEPA) filter at 99.99% efficiency. To protect critically sensitive environments, Ultra-Low Penetration Air (ULPA) filters, which are rated 99.999% efficient at retaining particles of 0.12 microns and larger in diameter, capture ultra-fine contaminants for ultra-sterilized air.

Additionally, HEPA filters comb air to remove pollen, tiny insects, bacteria, mold and other fungal spores that might be present during plant tissue culture or cannabis production. Contaminants such as these can find a way in via personnel or normal HVAC units and can blight crops, and if they are not caught, they can infect consumers as well. HEPA Filters help increase crop yields, meet regulations to pass inspection, and reduce contamination.

These filters also remove aerosol-born pathogens—germs that hitch a ride on larger particles and liquid droplets. HEPA- or ULPA-based FFUs can play an important role in infection prevention in surgical theaters, ICUs and other medical settings where the health of the patient depends on a sterilized environment.

FFUs are more than just a box to check on your ISO requirements list. They protect patients, personnel, products and so much more from the dangers of bacterial infection. FFUs keep medical and manufacturing facilities secure so that they can continue to create health solutions for the future without the worry of airborne pathogens.

Learn more Terra Universal Fan Filter Units here

Here is a list of common human pathogens that HEPA/ULPA filters capture and remove from circulation:

Pathogens: Bacteria and Diseases

- Escherichia coli: Gastrointestinal infection

- Bacillus anthracis : Anthrax

- Aspergillus brasiliensis: Sinus infections

- Francisella tularensis: Tularemia

- Bordetella pertusis : Whooping cough

- Mycoplasma pneumaoniae: Pneumonia

- Chlamydia pneumoniae: Bronchitis

- Clamydia psittaci : Psittacosis

- Klebsiella pneumoniae: Opportunistic infections

- Haemophilus influenzae : Meningitis

- Coxiella burnetii : Q fever

- Pseudomonas aeruginosa: Opportunistic infections

- Actinomyces israelii: Actinomycosis

- Legionella pneumophila: Legionaire's disease

- Thermoactinomyces sacchari: Farmer's lung

- Alkaligenes: Opportunistic infections

- Streptococcus pyogenes : Scarlet fever

- Mycobacterium Tuberculosis : Tuberculosis

Characteristics of Microbial Air Filters | Types of Filtration

Airborne filtration is a method to remove solids or liquid particles from an aerosol. Filtration is the most common method of cleaning indoor air.

There are four kinds of airborne filtration methods:

- Mechanical type – gravity dust collector, impinger, and cyclone

- Electrostatic force – single-stage electrostatic precipitator, double-stage electrostatic precipitator, etc.

- Washing – spray scrubber, water film precipitator, Venturi dust collector, etc.

- Filtration – filling-in filter, bag filter, etc.

Barrier-type filters can be used to remove particles, which include the following classifications:

- Granular layer

- Fibrous layer

- Microporous membrane

- Membrane-covered fibrous layer

- Screen mesh

- Perforated plate

Virtually every home, office, and facility integrates some type of fibrous, large pore filtration filter into its HVAC system. However, typical MERV filters are designed to intercept large-radius particles and are not an efficient method for intercepting more problematic microparticles, airborne viruses, spores, and allergens.

Continue to: Evaluating Filter Classifications and Performance | IEST vs EN Filters

Mechanisms of Microbial Filtration

Air filters are specifically designed to remove airborne particulate matter through several mechanisms.

Interception: The interception effect occurs when particles of a certain size approach the fibrous surfaces with the filter media. If the fiber pore radius is equal to, or smaller than the radius of an inbound particle, the larger particles will be intercepted and deposited on the fiber surface.

Diffusion: This particle entrapment method is a result of the Brownian motion, which describes a mechanism of particle behavior that is caused by the collision between gas molecules and particles. In this event, the random, swerving motion of particles passing through a filter's air stream makes them more likely to encounter and impact the filter media fibers.

Interception: Air filter interception occurs when a particle's mass and velocity force a particle outside of the airstream. Instead of flowing around the filter fibers, inertia will cause the particles to deviate from the streamline when approaching fibers, and then collide with and deposit on the filter media surface.

Gravitational Effect: Gravity-driven filtration is not widely used, but does play a factor in whether or not a particle will remain in an air stream, or deviate and be intercepted by the filter media. If a particle deviates from the streamline due to gravity, this filtration method is deemed gravitational deposition.

Electrostatic Effect: This filtration mechanism occurs when charges may exist on both fibers and particles. When charged particles encounter polarly charged surfaces, the electrostatic effect attracts particles.

Understanding PM Ratings for Biomedical and Clinical Studies (PM 1.0 | PM 2.5 | PM 10)

Numerous epidemiological, biomedical, and clinical studies indicate that ambient particulate matter (PM) in air pollution is strongly associated with increased cardiovascular disease such as myocardial infarction (heart attack), cardiac arrhythmias, ischemic stroke, vascular dysfunction, hypertension, and atherosclerosis.

PM (particulate matter) ratings categorize particles based on their size (radius). Particle size is the most common method of theorizing how particles will react and perform (buoyancy, hang time, penetration, capture efficiency, ect) under various air conditions (temperature, pressure differential, air velocity, humidity).

PM 1.0 (1.0 μm) PM2.5 (2.5 μm) and PM10 (10 μm) are of particular interest in epidemiological studies. These pesky particles are small enough to be invisible to the naked eye, yet remain airborne for long periods of time. Due to their small size and abundance, they are readily inhaled by the lungs.

| PM Rating | Particle Size | Nano Meter Size |

| PM 1.0 | <1.0 μm | <100 nm |

| PM 2.5 | <2.5 μm | <250 nm |

| PM 10 | <10 μm | <1000 nm |

Continue to IEST vs EN HEPA Filter Classifications and Performance

Need Help Identifying a Filtration Solution for Your Facility?

Shop Terra Universal Products Online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra Sales Specialist via phone, webchat, or email for help with configuration, large purchases, and application expertise.

Not Finding the Answer You Were Looking For?

For expanded information on HEPA filtration solutions and considerations, continue on to other articles in this series.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731