- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

A Practical Guide to Vacuum Pressure and Measurement

Posted:

May 14, 2024

Categories:

Vacuum Chambers

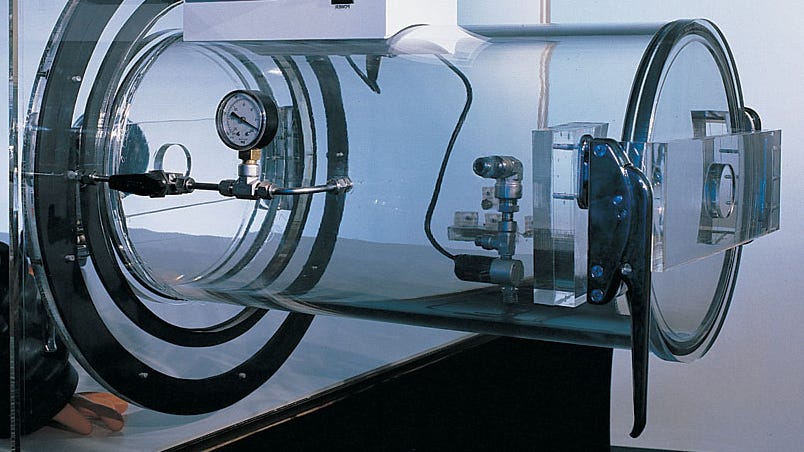

As an American manufacturer of vacuum chambers and their associated systems, Terra Universal offers an array of vacuum chamber designs for material testing, thermal testing, stress testing, degassing, atmospheric simulation, and more. In this series, we'll discuss smaller benchtop vacuum chambers for small parts, as well as large high-capacity vacuum chamber models for extra large assemblies or components. Additionally, we'll discuss configurable add-ons such as vacuum pumps, vacuum control modules, vacuum gloveboxes, and vacuum chamber material selection criteria. Whether it's a lab, cleanroom, or unspecified research environment, Terra offers thousands of ready-to-ship products, as well as custom-fabricated solutions for unique applications.

- Vacuum Chamber Measurement and Operation

- Vacuum Chambers for Stress and Pressure Testing (You are Here)

- Vacuum Chambers for Atmospheric Simulation and Testing

- Vacuum Chambers for Leak Testing, Vacuum Drying, Degassing

What is Thermal Stress Testing for Vacuum Applications?

Thermal Vacuum Testing subjects materials or equipment to both vacuum conditions and extreme temperatures, both hot and cold. These tests evaluate material and component performance between ambient and operational temperatures. Aerospace components and space vehicles may require more extreme simulations that reproduce hot-to-cold cycles experienced by a craft that is entering or exiting a planetary atmosphere. Importantly, these tests help researchers understand the combined effects of temperature and pressure values over short cycles or longer sustained periods.

Thermal stress testing is a crucial method for assessing how materials and electronic devices behave under extreme temperatures. This type of testing helps ensure that products can withstand and operate under varying environmental conditions they might encounter during use. Thermal stress testing applications include, but are not necessarily limited to:

Temperature Humidity Bias Testing (THB): THB testing exposes components to high temperatures and high humidity simultaneously to accelerate corrosion and other moisture-induced failures. It's particularly useful for evaluating the reliability of non-hermetic packaged devices.

High Temperature Operating Life (HTOL) Testing: HTOL testing subjects devices to high temperatures for extended periods to simulate long-term operation conditions. This test is commonly used in the semiconductor industry to assess the reliability of integrated circuits and other electronic components over their expected lifetimes.

HAST (Highly Accelerated Temperature and Humidity Stress Test): An advanced version of THB, HAST uses higher pressures to accelerate humidity and temperature stress, allowing for quicker identification of potential failure mechanisms in a shorter amount of time compared to traditional THB.

Thermal Shock Testing: This test rapidly alternates extreme temperatures to simulate quick changes in conditions. The purpose is to ensure the material or device can endure sudden changes without failure. It is especially important for electronics and composite materials that may experience quick temperature changes in operational environments.

Thermal Cycling Testing: Similar to thermal shock testing, thermal cycling involves repeatedly heating and cooling a product over numerous cycles but at a slower rate. This type of testing helps identify potential failures from thermal fatigue due to the expansion and contraction of materials.

Steel and Aluminum Vacuum Chambers for Thermal Stress & Material Testing Applications

Steel and Aluminum Vacuum Chambers play a pivotal role in scientific research and industrial processes, offering unparalleled precision and control in controlled environments. The preference for aluminum and stainless steel chambers for stress testing applications delineates several attributes that are important for accurate and repeatable results. All of Terra's metal vacuum chambers are cleanroom rated, and readily support contamination-sensitive applications for cleanroom and labs. Importantly, these materials will not permeate or outgas like acrylic designs.

Steel and aluminum chamber materials afford leak integrity at sustained low pressure over longer periods, as well as a host of other benefits including chemical compatibility, ESD-safe characteristics, thermal conductivity, and easy cleaning. In environments that are sensitive to minuscule changes in pressure levels, ambient temperature, humidity, or trace contamination, aluminum and stainless steel chambers are the preferred medium.

Stainless Steel Benchtop Vacuum Testing Chambers: For thermal vacuum tests in a completely isolated environment, a stainless steel vacuum chamber is ideal in terms of thermal conductivity, allowing for efficient heating and cooling cycles. Additionally, it can withstand higher temperatures involved with certain types of vacuum chamber tests. Stainless steel is a preferable material for high moisture applications, as it offers a higher degree of protection from rust and oxidation than aluminum models. Terra's double-wall stainless steel chambers support vacuum levels down to 29.9" Hg.

Stainless steel offers the highest degree of durability, cleanliness, and heat/chemical resistance, making it useful for a wider range of corrosive or thermal-dependent processes such as chemical processing, films, coatings, and curing operations. Stainless steel is also the most common choice for hygienic environments that require low levels of contamination such as labs, cleanrooms, and research environments that require frequent and harsh decontamination treatments.

Aluminum Benchtop Vacuum Chambers: For vacuum applications that require the introduction of heating and cooling systems for internal temperature management and monitoring, aluminum vacuum chambers offer a softer material that is easier and less costly to machine, therefore rendering cost savings when factory modifications are required to integrate power cables, data feeds, or heating and cooling systems. For certain thermal applications that require rapid heat cycling, aluminum is sometimes preferential to stainless steel because it heats up quickly and cools quickly with less energy requirements. Powder-coated aluminum chambers offer enhanced chemical resistance when using disinfectants, such as isopropyl alcohol, or sporicidal agents. Regarding thermal properties, aluminum vacuum chambers transfer heat quickly and efficiently, which can be essential for temperature-sensitive processes, such as thermal cycling. However, this characteristic also makes these chambers more sensitive to environmental drift via changes in ambient air temperature, or when placed nearby to heat-generating equipment.

High Capacity Vacuum Chambers for Material and Stress Testing

High Capacity Stainless Steel Vacuum Chambers are meticulously designed for specialized industrial and laboratory applications. Crafted from durable 304 stainless steel and featuring a robust aluminum door, this chamber measures 27 inches in width, 48 inches in depth, and 23.44 inches in height. The unit supports a maximum vacuum of 29.9 inches of mercury, ensuring unrestricted capabilities conditions for various vacuum processes. The chamber's internal construction includes an 18-inch wide shelf capable of supporting up to 75 pounds, making it suitable for handling substantial loads. Visibility and monitoring are facilitated by a window made from one-inch thick polycarbonate, with a diameter of 8.57 inches, which provides both safety and convenience.

Need Help Configuring a Vacuum Chamber System?

As a manufacturer of vacuum chamber systems, Terra Universal offers a deep pool of factory expertise and end to end solutions with globally honored pricing and worldwide delivery.

Shop Terra Universal Online to browse a wide selection of vacuum chamber systems, accessories, and add-ons including chambers, vacuum pumps, vacuum feedthroughs, humidity control solutions, and nitrogen purge systems.

Contact us or request a quote for custom orders including atypical chamber sizes, gas purge solutions, vacuum pumps, feedthroughs, custom gauges, and other accessories.Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731