- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Desiccators

-

Posted: August 08, 2022Categories: DesiccatorsRead more »

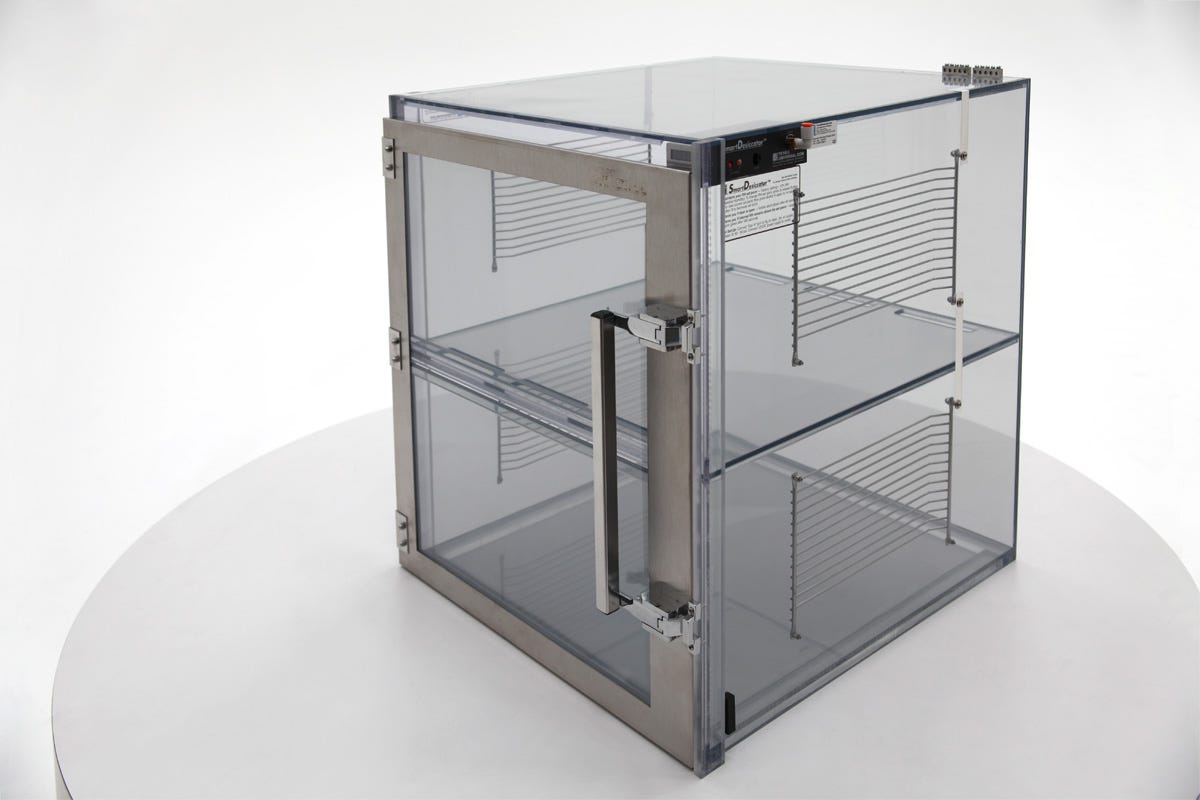

A desiccator, also referred to as a dry box or dry cabinet, is a humidity-controlled chamber that produces a dry, clean environment conducive to the storage of sensitive materials, samples, or components.

-

Posted: February 19, 2021Read more »

You need to protect sensitive samples, but you don’t want to overpay. Below is a list of application descriptions to help choose the best desiccator storage system for your application and budget.

-

Posted: February 18, 2021Read more »

Inert nitrogen gas is commonly used in laboratories to control the atmosphere for highly sensitive equipment and procedures. The best way to maintain the environment in a desiccator cabinet, glove box, or similar enclosure, is to automatically purge the environment with nitrogen or argon gas. Because these processes happen automatically based on humidity set-points, smart controllers and sensors allow for more trackable, traceable, and efficient results.

-

Posted: June 12, 2020Categories: DesiccatorsRead more »

How to Prevent Moisture Damage with a Desiccator Cabinet

On a grand scale, every desiccator cabinet looks similar: air-tight chambers, meant to keep components inside safe from humidity and particulate contamination during storage. It’s not until you need one that you consider what distinguishes one desiccator from the next, and how those differences will affect the material you need to preserve. So if you’re wondering what kind of desiccator cabinet is available, what problems to avoid and what features are used to achieve superior desiccation, read on.

-

Posted: February 19, 2020Read more »

Terra offers desiccator and desiccator cabinet designs for every purpose - whether it be for transportation, short term or long term storage, these dry cabinets protect sensitive parts and materials of all shapes and sizes from moisture damage, particle contamination, electro-static discharge, and more. Find out which design best fits your needs!

-

Posted: February 05, 2020Read more »

Forget about renting nitrogen tanks — laboratory applications aren’t on the same level as buying helium for a kid’s birthday balloons. Critical operations can’t wait for resupply. What happens when production stops because the gas supply has depleted, or when valuable experiments or products are ruined because of moisture exposure? As far as the old-fashioned nitrogen delivery via tank and truck, why wait to have crucial laboratory supplies left on the cleanroom stoop like old milk bottles? How much time should personnel have to spend refilling each tank? And where in the space-starved facility should the bulky supplies wait for use?

-

Posted: April 30, 2019Categories: DesiccatorsRead more »

Door Alignment

Proper alignment of doors will prevent excessive gas escape and ensure door sensor alignment. Some leakage, however, is normal. Because cabinets operate under varying degrees of positive pressure, Terra door gaskets are designed to allow controlled gas escape.

All cabinets are checked prior to packaging to ensure proper door alignment. However, they can come out of alignment during shipping due to the inherent flexibility of plastic.

Doors feature sensor magnets that must be aligned with the associated sensor on the desiccator door. If these magnets are misaligned, the Dual Purge™ system may not function properly, and door seals may not seat properly, allowing nitrogen leakage.

On a properly aligned, level cabinet, all door latches are engaged directly in

-

Posted: April 15, 2019Categories: DesiccatorsRead more »

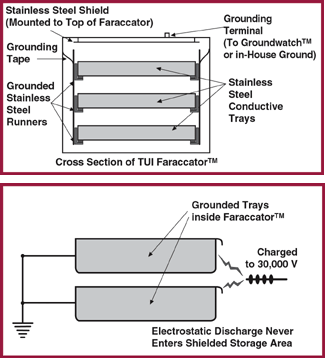

- What is electrostatic discharge?

- How is it generated?

- How does it damage microelectronic devices?

- How can it be controlled?

- What are the advantages and disadvantages of static control methods available today?

Why all the Static?

Static electricity is an excess or deficiency of electrons on a surface. The total number of deficient or excess electrons determines the charge on that surface. A surface exhibiting an excess of electrons is charged negatively, and an electron-deficient surface is charged positively.

How are Electrostatic Charges Generated?

Electrostatic charges are usually generated by friction between and/or separation of two dissimilar materials, at least one of which is a nonconductor or a poor conductor of electricity. The accumulated charge (static) resides on the surface of, rather than within, the charged nonconductive object.

-

Posted: April 01, 2019Categories: DesiccatorsRead more »

Terra offers a comprehensive range of application-specific desiccator cabinets and nitrogen control systems. These performance concepts will help you select the system right for your application.

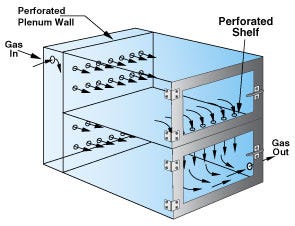

Nitrogen is the standard medium for contamination-free storage because it is relatively inert—it neither reacts with stored materials nor carries moisture—and because it can be isolated and purified relatively inexpensively.

Desiccator cabinets must be set up so that an appropriate flow of nitrogen forces out all moisture- and contamination-laden air. Because nitrogen has a lower specific gravity than air, it is introduced into the upper section of the desiccator; the heavier air is then purged out of the bottom.

Failure to maintain the appropriate

-

Posted: March 15, 2019Categories: DesiccatorsRead more »

Compare Terra's Advanced Designs and Fabrication Experience

At first glance, most desiccators look pretty similar. It's not until you put them into service—and fill them with delicate, expensive parts—that differences in quality become apparent.

When you invest in a Terra desiccator cabinet, you benefit from 40 years of design innovation and manufacturing experience. Simply put: Terra desiccators function better and function longer.

Doors

The First Failure Point of a Desiccator Cabinet - Terra's full 304 stainless steel door frames offer the strongest door construction in the industry

Terra's stainless steel door frames eliminate