- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO

Passthrough chambers are used in cleanrooms and controlled environments across countless industries and applications. Passthrough cabinets have many benefits. Aside from reducing foot traffic in controlled areas, they also help meet special cleanliness, safety, and security requirements in different industries. For instance, pharmaceutical cleanrooms require compliance with USP <797> and USP <800> guidelines for compounding sterile medications and hazardous drugs. Other cleanrooms and labs handling biohazards require similar strict sterilization protocols, plus autoclave-safe designs. Facilities manufacturing sensitive electronics may not require frequent sterilization, but may have other special requirements for ESD-safety and controlled air spaces to minimize particle counts inside the cleanroom.

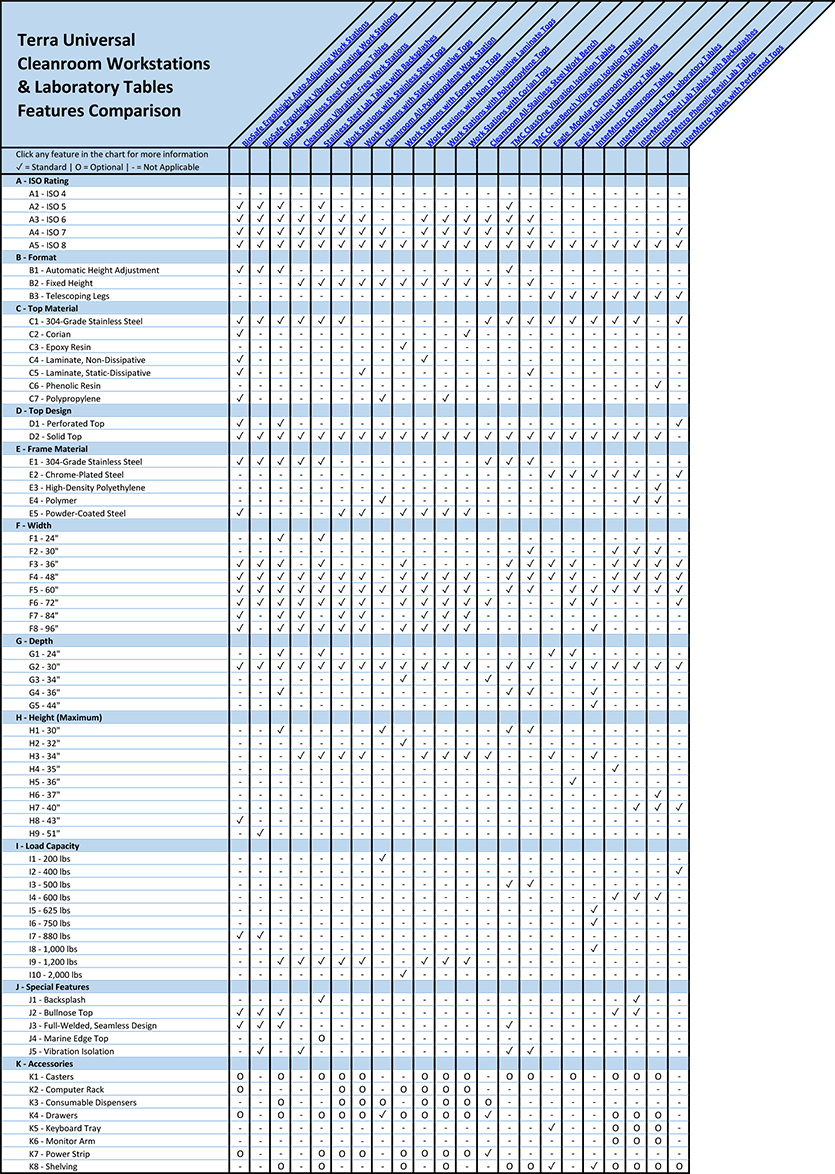

Terra Universal manufactures application-specific cleanroom workbench packages for a variety of uses, many available for immediate shipment and delivery from its Fullerton, California facility.

Terra also offers a wide selection of cleanroom specialized equipment from the following manufacturers:

Eagle (on-budget cleanroom tables and storage)

Metro (gowning furniture, modular tables, keyboard trays, monitor arms & drawers)

TMC (pneumatic vibration-isolated tables)

View All Cleanroom Workstations and Tables

ISO 14644-1 is a widely recognized

Terra Universal’s cleanroom doors are designed for quick and easy installation into operating rooms, surgical suites, stick-built or modular cleanrooms. Designed for health care, pharmaceutical, and CGMP facilities, Terra’s cleanroom doors are easy-to-sterilize, maintain room pressure and resist common biocides and hospital-grade disinfectants.

Compare cleanroom fan filter types and FFU features including airflow design, size, motors, construction, control systems, and compatible accessories.

Laminar flow air and positive pressure cleanroom design are ideal for non-hazardous, ultra-clean applications. Positive pressure mitigates dirt from entering the cleanroom when opening doors or pass-through chambers. Laminar airflow design ensures that air maintains a singular, uniform direction and velocity from intake to exhaust port. Terra's positive pressure cleanrooms include HEPA filtration systems capable of ISO Class 3 - ISO Class 8 air quality conditions. ULPA filtration units are available for the most sensitive ISO 3 - ISO 5 product applications including pharmaceutical compounding, semiconductor wafer processing, sterile packaging, and micro-nanofabrication.

Terra Universal’s cleanroom windows are designed for quick and easy installation into stick-built or modular cleanrooms. Configured for health care, pharmaceutical, and CGMP facilities, Terra’s cleanroom windows are easy-to-clean, hygienic, support aseptic environments and enhance the visibility of operations and foot traffic.

Terra’s broad portfolio of cleanroom window designs includes flush-mount, crevice-free, frameless BioSafe windows, economical, framed ValuLine windows, and special-application designs including UL-listed and fire-rated windows. Switch Glass windows and internal blinds are optional for high privacy areas.

There are compelling reasons to choose either airflow system depending on clearance requirements, process location, work surface design, and operator safety. Below is a brief comparison (read more on horizontal vs vertical laminar flow hoods).

For retrofit projects converting an existing lab space into a cleanroom or cGMP area, the conventional solutions each come with unique challenges. New facility builds are cost-prohibitive, carry lengthy timelines, and hinge on the acquisition of a suitable facility. Depending on area requirements, installing a modular cleanroom inside an existing room is a fast, economical alternative, but often creates unusable or inaccessible space.

Universal BioSafe Benchtop Hoods are a UL-Listed product manufactured by Terra Universal. "Universal" flow hoods designate a modular design that can achieve nine different configurations from a single flow hood.